Release Date:2025-03-28 16:24:02 Popularity:

In industrial manufacturing, O-ring sealing washer is an important sealing element widely used in the field of hydraulics, pneumatics, mechanical equipment and automobile manufacturing. Its main role is to prevent liquid or gas leakage, to ensure the normal operation of equipment. Traditionally, O-ring sealing washer assembly mostly adopts manual operation or semi-automatic equipment, but with the expansion of production scale and the development of automation technology, O-ring sealing washer automatic assembly machine came into being. The equipment can be automatic loading, accurate assembly, detection and rejection and packaging, significantly improve the production efficiency and assembly precision, and become a seal manufacturer to improve the competitiveness of the tool.

First, the working principle and structure of O-type sealing gasket automatic assembly machine

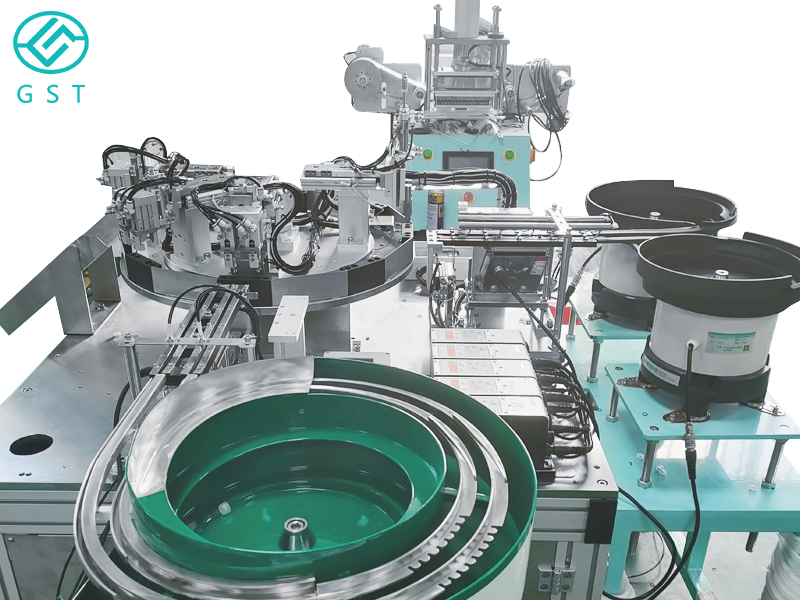

1.O-type sealing washer automatic assembly machine mainly adopts automatic feeding, robotic gripping, assembly positioning and automatic detection and rejection technology to realize the efficient assembly of sealing washers. Its basic workflow includes:

Automatic loading: gaskets and assembled parts (such as shafts, bolts, spools, etc.) are automatically loaded by vibrating disk or linear feeder and transferred to the assembly station.

Automatic assembly: robot or special fixture will grab the gaskets and accurately assemble them to the fittings being assembled to ensure the accurate position and sealing.

Detection and rejection: The equipment is equipped with visual inspection and displacement sensors to detect the assembly effect in real time and reject defective products.

Automatic discharging and packaging: qualified products are automatically discharged into the packaging station or receiving container.

2.O-type sealing gasket automatic assembly machine is mainly composed of the following parts:

Feeding system: Adopt vibrating plate, linear feeder or silo to feed materials automatically to ensure smooth feeding of gaskets and assembled parts.

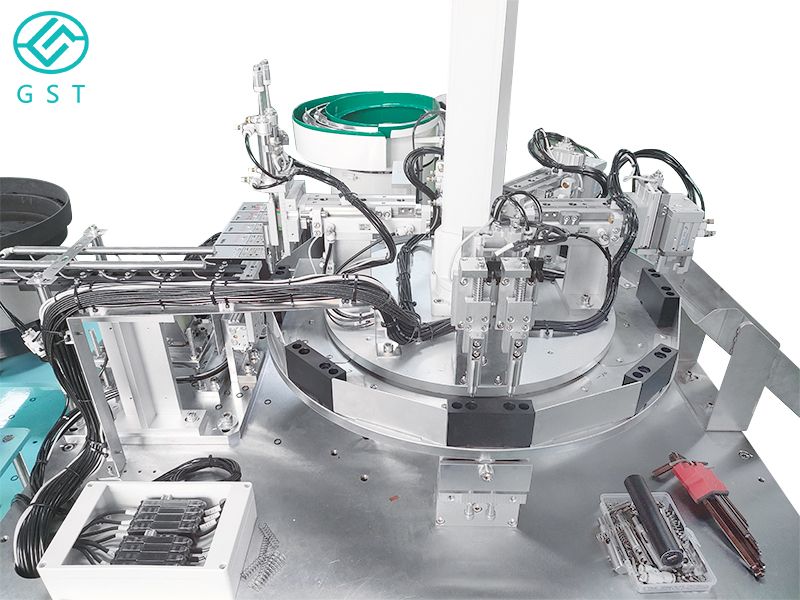

Assembly system: adopt manipulator, servo motor or cylinder drive mechanism to realize automatic gripping and precise assembly of gaskets.

Detection and Rejection System: Equipped with visual inspection and displacement sensor to monitor the assembly quality in real time and automatically reject defective products.

Control system: PLC control and touch screen operation can adjust the assembly speed, detection accuracy and production parameters.

Discharging and packaging system: qualified products are automatically collected or put into the packaging equipment to realize automatic assembly line operation.

Second, the technical characteristics of O-type sealing gasket automatic assembly machine

1. Automation and efficient production: fully automatic feeding and assembly, replacing traditional manual operation. Single machine can assemble tens to hundreds of seals per minute, the efficiency far exceeds manual assembly. It can be linked with automatic packaging line or testing equipment to realize automatic production.

2. High assembly precision and stable quality: Adopt precise positioning and assembly mechanism to ensure the fit of O-ring and workpiece. Equipped with visual inspection and size monitoring system to monitor the assembly effect in real time. High assembly precision reduces leakage problems caused by poor sealing.

3. Flexible adaptation to a variety of specifications: the equipment supports a variety of specifications of O-ring gaskets and workpiece assembly. By replacing the fixture or adjusting the parameters, it can realize the fast switching of different specification products. Suitable for small quantities of multiple varieties or large quantities of single-species production mode.

4. Fault alarm and automatic rejection function: the equipment is equipped with automatic detection and fault alarm system. Once there is assembly deviation, substandard products or equipment abnormality, it can automatically shut down and reject the defective products. Ensure production stability and quality pass rate.

As a key equipment to improve efficiency and quality in modern industrial production, O-ring gasket automatic assembly machine has been widely used in automobile manufacturing, home appliances and electronics, hydraulics and pneumatics and medical food and other fields. With high efficiency, precision and automation, it effectively improves production efficiency, reduces labor costs and ensures stable product quality. In the era of intelligent manufacturing, this equipment will continue to promote the development of the seal assembly industry in the direction of high efficiency, intelligence and automation.