Release Date:2025-07-16 15:25:05 Popularity:

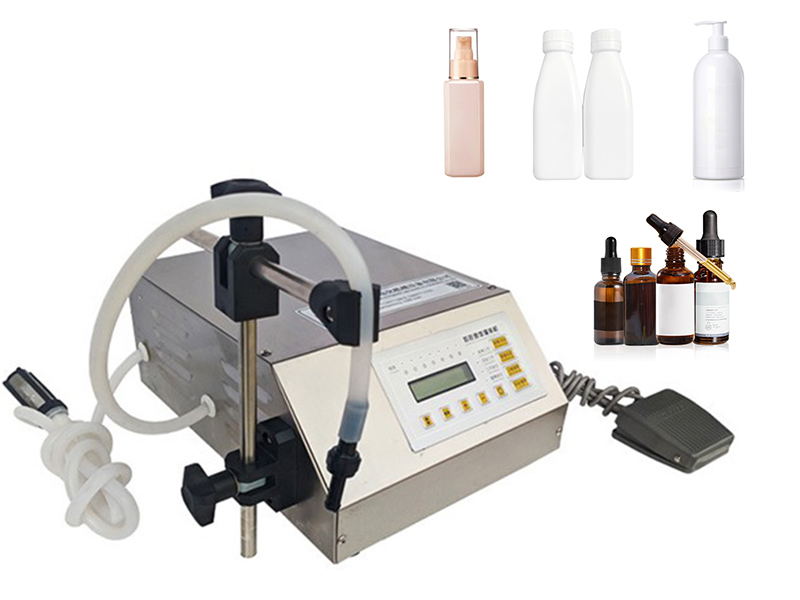

The automatic filling machine for alcoholic beverages is an automated equipment for fast, accurate and clean filling of various liquid alcoholic beverages. It can not only complete automatic bottle sorting, quantitative filling, automatic capping and capping, but also cooperate with the back-end labeling, coding and packing system to realize unmanned operation of the entire filling production line. This equipment is widely used in the standardized production of bottled liquor, red wine, rice wine, beer and fruit wine, which can effectively improve production capacity, ensure filling accuracy, and greatly reduce labor costs.

1. Equipment structure and main functions

Bottle sorting system: automatically sort and position bulk empty bottles, and transport them to the filling area to improve the overall production rhythm.

Filling system: according to the different types of alcoholic beverages, normal pressure, negative pressure, equal liquid level or flow meter filling methods are adopted to ensure the consistency of the liquid level in the bottle and the stable filling without bubbles.

Anti-drip filling nozzle: The filling head is equipped with an anti-drip design to prevent the spillage of alcoholic beverages from contaminating the bottle and equipment, and keep the filling environment clean.

Screw or press cap system: adapt to different bottle caps (such as screw caps, corks, metal anti-theft caps), automatically complete the capping, pressing, tightening and other actions, and seal reliably.

Intelligent control system (PLC + touch screen): the equipment operation adopts human-machine interface management, the filling speed, time, and capacity can be adjusted, and it has real-time monitoring and fault alarm functions.

Conveying system and supporting interface: after filling, it is automatically transported to the labeling, coding or packing module to realize the linkage production of the whole line.

2. The core advantages of automatic wine filling machine

High filling accuracy: with the help of flow meter, servo system or electronic weighing module to control the filling volume, the error can be controlled within ±1ml, meeting the quality consistency requirements of high-end wine brands.

High-efficiency capacity output: multi-head filling design (4 heads, 8 heads, 12 heads, etc. are optional), thousands of bottles of wine can be filled per hour, suitable for batch operations in medium and large factories.

Adapt to a variety of bottle types and wines: The equipment is compatible with glass bottles, plastic bottles, ceramic bottles and other bottle types and capacities, and supports a variety of wine types such as white wine, red wine, sake, and fruit wine.

Hygienic and safe, easy to clean: The parts in contact with the wine are made of food-grade 304/316 stainless steel, equipped with a CIP online cleaning system to ensure equipment cleanliness and food safety.

Save labor costs and easy operation: Fully automatic operation only requires 1-2 people on duty, greatly reducing the intensity of manual labor and the pressure of enterprise employment.

Automatic wine filling machines are becoming a "weapon" for wine companies to achieve intelligent production with their multiple advantages such as high precision, high efficiency, and high compatibility. It not only improves production efficiency and saves labor costs, but also ensures the hygiene and consistency of products, and effectively enhances brand reputation. With the continuous advancement of technology and the upgrading of consumption structure, automatic wine filling machines will play an increasingly important role in the industry in the future, helping Chinese wine brands go global and move towards a new stage of high-quality development.