Release Date:2025-07-17 13:59:03 Popularity:

Under the background of rapid development of modern manufacturing industry, standardized equipment can no longer meet the diversified, personalized and flexible production needs of enterprises. More and more enterprises are beginning to turn their attention to the customization of automation equipment to improve production efficiency, optimize process flow, reduce labor costs and enhance market competitiveness. Customization of automation equipment is gradually becoming an important driving force for promoting industrial upgrading and intelligent manufacturing transformation.

1. Definition and characteristics of automation equipment customization

Automation equipment customization refers to the development, design and manufacture of non-standard automation equipment that meets the specific needs of the customer's actual process flow, product characteristics, production scale and spatial layout. Compared with traditional standard equipment, customized equipment is more highly matching, flexible and targeted, and can achieve "process-specific, functional integration, and optimal performance".

Its main features include:

Personalized design: tailored according to the unique production needs of the enterprise, accurately matching the actual process flow.

Modular combination: multiple functional modules are freely combined and expanded to adapt to future production line upgrades.

Intelligent control: PLC, human-machine interface, visual system, robotic arm and other intelligent control technologies are widely used to achieve unmanned operation.

Significant efficiency improvement: Through the integration of automatic feeding, processing, testing, packaging, etc., production efficiency and product consistency are significantly improved.

2. Main application areas of customized automation equipment

With the continuous evolution of industrial technology, customized automation equipment is widely used in many fields, including but not limited to:

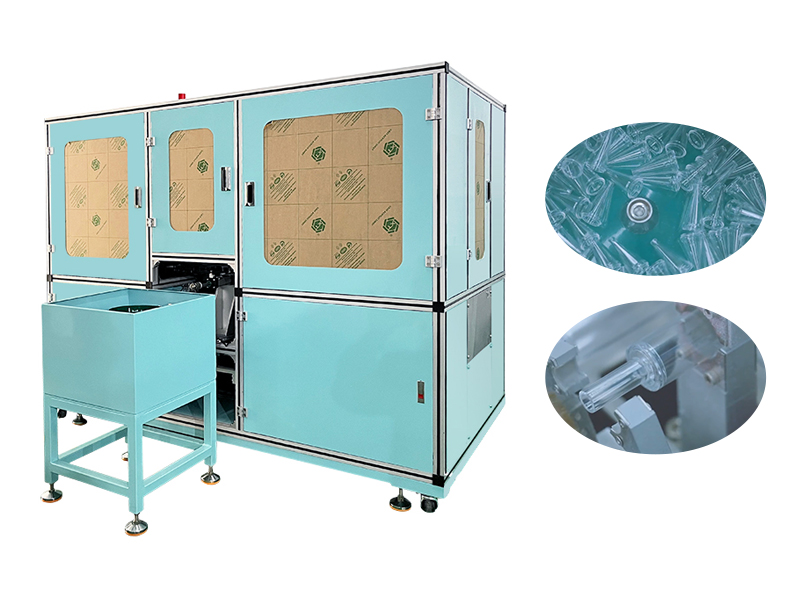

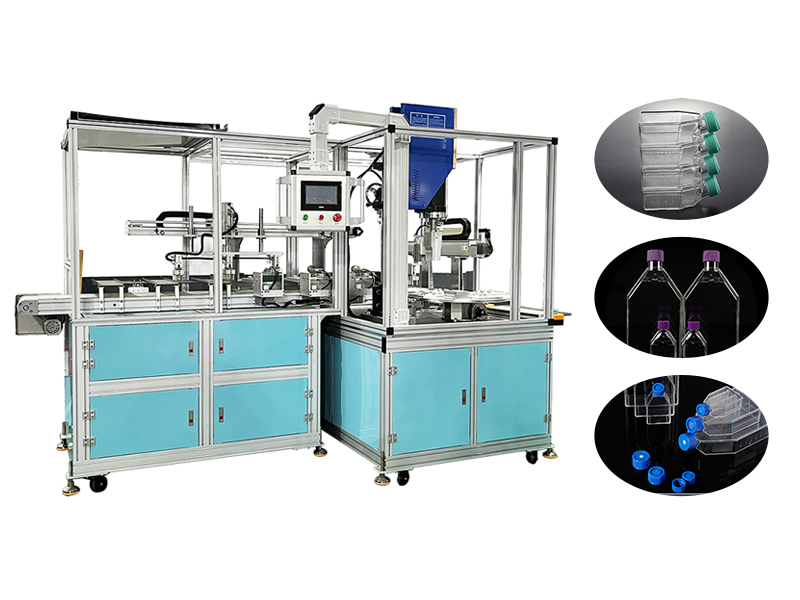

Medical device industry: customized pipette assembly machines, dental mirror automatic assembly lines, pipette tip plug core boxing machines, etc., to meet high cleanliness and high precision requirements.

Daily chemical and food packaging: such as quantitative filling machines, automatic labeling machines, intelligent packaging lines, etc., to improve production speed and packaging quality.

Automotive parts manufacturing: customized equipment such as automatic riveting assembly and parts conveying systems to achieve high-intensity operation automation.

3C electronics industry: used for precision assembly, welding, dispensing, testing and other links to ensure high-precision assembly of tiny components.

Plastic product molding and assembly: such as hanger flocking machines, trouser rack automatic assembly machines, etc., to meet the processing and treatment of various forms of plastic parts.

3. Advantages of customized automation equipment

Improve efficiency and reduce costs: Replace traditional labor with automated equipment, greatly reduce the number of workers and manual errors, improve production line operation efficiency, and reduce scrap rate.

Enhance product consistency and quality controllability: Stable and accurate equipment movements ensure standardization of product size, function, etc., and achieve consistent mass production quality.

Strengthen corporate competitiveness: Quickly respond to market changes and flexibly adjust production capacity and product types, which is conducive to enterprises seizing the initiative.

Optimize space and process layout: Customize equipment size and function layout according to on-site working conditions to maximize space utilization and smoother production flow.

Beneficial to data collection and intelligent management: Can be integrated with MES, ERP and other systems to achieve visual management of production processes, real-time monitoring of equipment status, data traceability and other functions.

4. Brief description of customization process

A complete automation equipment customization process usually includes:

Demand research: In-depth understanding of the customer's basic situation such as products, production capacity, processes, and environment.

Scheme design: The engineering team draws preliminary scheme drawings to confirm the functions and configurations of each module.

Prototype trial production: manufacture test equipment prototypes, conduct debugging and verification.

Formal production: optimize the design based on trial production feedback and start mass production.

Installation, commissioning and training: install, run and test the equipment after it arrives at the customer site and train operators.

After-sales service: provide continuous technical support, equipment upgrades and maintenance services.

Under the wave of intelligent manufacturing, standard equipment can no longer meet the multiple demands of all industries for efficiency, quality and flexibility. Automation equipment customization, as a key solution integrating technological innovation and industrial applications, is helping more and more companies achieve production automation, intelligent operation and digital management. In the future, with the in-depth integration of artificial intelligence and industrial Internet, automation equipment customization will play a more core role in promoting industrial upgrading and high-quality development. Choose customization, choose the future!