Release Date:2025-07-18 15:23:19 Popularity:

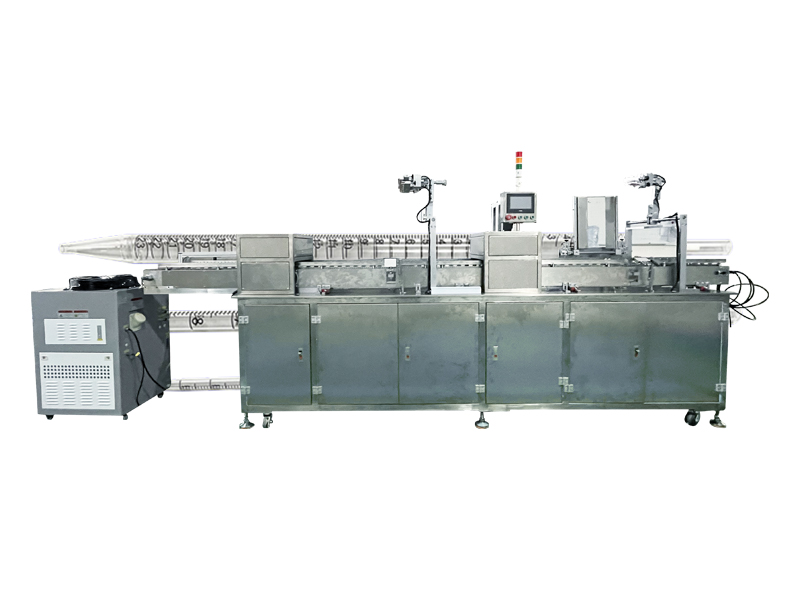

A two-color automatic screen printer is an automated device that can realize continuous printing of two color patterns. It is suitable for products with different appearances such as round, flat, and special shapes. It uses a multi-station automatic transmission system, a precision positioning device, and two independent screen printing mechanisms to complete two screen printing operations of different colors or patterns after the product is clamped once, thereby improving production efficiency and ensuring accurate pattern position and consistent color.

1. Equipment structure and workflow

A standard two-color automatic screen printer is mainly composed of the following parts:

Automatic feeding system: automatically arranges and transports the products to be printed to the printing station;

Precise positioning system: achieves high-precision positioning through manipulators, photoelectric sensors, or visual recognition technology;

Dual printing head structure: two sets of screen printing mechanisms can work synchronously or continuously to complete different color printing respectively;

UV curing or hot air drying system: ensure that the ink is dried immediately after printing, improving efficiency and quality;

Automatic unloading system: automatically collects the products after printing, which is convenient for subsequent process connection;

PLC control system: set parameters through the touch screen, monitor various operating states in real time, and operate intuitively and conveniently.

2. Main application areas

Two-color automatic screen printers are widely used in the following industries:

Medical equipment: such as centrifuge tubes, pipettes, test tubes and other plastic consumables scale lines and logo printing;

Electronic components: printing text and logos on products such as resistors, capacitors, connector shells, etc.;

Cosmetic packaging: used for printing bottle LOGO, instructions and patterns;

Daily plastic products: such as water cups, pencil cases, toothbrush handles, etc. brand pattern printing;

Hardware and plastic industry: two-color logo printing on smooth or special-shaped parts.

3. Advantages of two-color automatic screen printer

Efficiency improvement: Compared with traditional single-color printing and manual color change, the two-color automatic screen printer can complete two-color printing at one time, greatly shortening the production cycle;

High printing accuracy: Adopting high-precision servo drive and positioning mechanism to ensure no offset between the two printings and accurate pattern overlap;

Save labor costs: The fully automatic loading, printing and unloading process can replace 3 to 5 workers, especially suitable for large-volume orders;

Strong adaptability: The jig can be customized according to the product size and shape to adapt to workpieces of different specifications;

Good stability and consistency: Automated control avoids human errors, making the printing quality of batch products highly consistent;

Wide ink compatibility: Suitable for a variety of printing materials such as UV ink, solvent-based ink, and thermosetting ink.

As an efficient representative of printing equipment, the two-color automatic screen printer is gradually replacing traditional manual and single-color equipment, and has become an important tool for manufacturing companies to improve printing quality and create brand image. For companies pursuing high efficiency and high quality, investing in a two-color automatic screen printer is not only an optimization of production means, but also an important step in improving corporate competitiveness.