Release Date:2025-03-28 15:58:41 Popularity:

In the fields of biopharmaceuticals, scientific research experiments, cell culture and vaccine development, culture flasks are a commonly used container. Its quality is directly related to the experimental effect and product safety. Traditional culture bottle welding mainly relies on manual or semi-automatic equipment, there are problems such as low efficiency, uneven welding, high labor costs, and it is difficult to meet the needs of mass production. As a kind of automatic equipment designed for culture bottle manufacturing, culture bottle automatic welding machine has become the key equipment in the field of biopharmaceutical and laboratory equipment production through accurate welding, high efficiency, strong stability and other advantages.

I. Working principle and structure of culture bottle automatic welding machine

1. The automatic welding machine for culture bottle adopts ultrasonic welding, heat fusion welding or laser welding technology, and realizes the efficient welding of bottle body and bottle cap, bottle neck and bottle bottom or bottle body and interface through the automatic control system. Its basic workflow includes:

Feeding and Positioning: The automatic feeding device transfers the culture bottles to the welding station and positions them accurately.

Welding operation: ultrasonic or hot melt welding technology is used to weld the bottle neck, bottle bottom or interface to ensure firmness and sealing.

Cooling and curing: After welding is completed, the equipment automatically carries out cooling treatment to ensure the stability of the welding area and prevent deformation.

Automatic inspection and rejection: Equipped with online inspection system to inspect the welding quality, if there is any bad welding or leakage welding, it will automatically reject the non-conforming products.

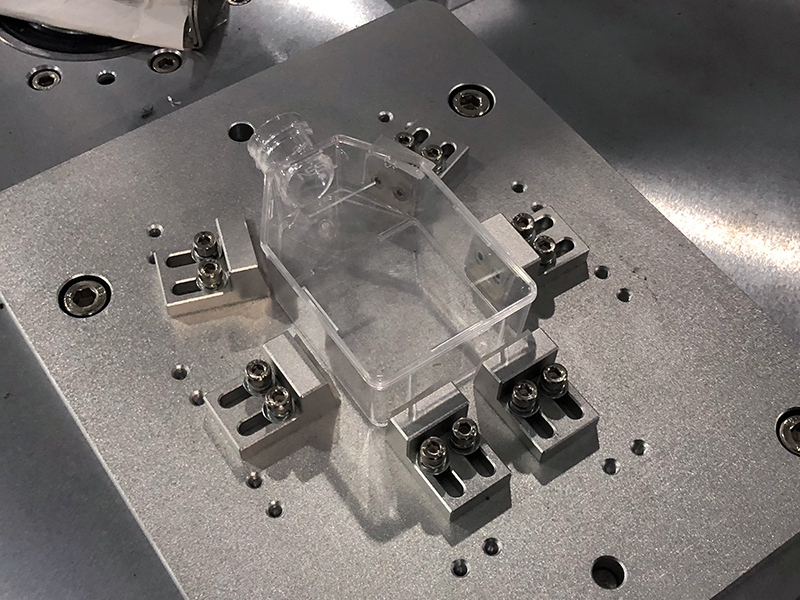

2. The automatic welding machine for culture bottle mainly consists of the following parts:

Feeding system: Automatically conveying the culture bottle to the welding position. It often adopts turntable type, linear type or mechanical hand feeding.

Welding system: the core part, using ultrasonic, thermal fusion or laser welding technology to realize the welding of bottle body and bottle cap or bottle neck.

Control system: PLC control and touch screen operation interface are adopted to realize automatic operation and parameter adjustment.

Inspection and Rejection System: Equipped with visual inspection and sensor monitoring, automatic inspection of welding quality and rejection of defective products.

Cooling system: cooling the bottle after welding to prevent deformation and ensure welding stability.

Welding technology of culture bottle automatic welding machine

1. Ultrasonic welding technology: the use of high-frequency vibration friction heat to realize the fusion of the plastic bottle body and bottle cap or bottle bottom. The welding speed is fast, and the welding seam is beautiful and firm. Suitable for PP, PE, PS, PET and other materials culture bottle welding.

2. Hot melt welding technology: By heating the welding head, the welding part of the culture bottle will melt and combine. The welding effect is firm and suitable for thick-walled bottles or welding of specific materials.

3. Laser welding technology: adopts high energy laser beam to melt the connection between bottle body and cap or bottle bottom. Welding precision, suitable for high-precision and high cleanliness requirements of the production occasions.

Advantages of automatic welding machine for culture bottle

1. Improve productivity and reduce labor costs: automatic welding machine can realize high-speed continuous welding, productivity is much higher than manual or semi-automatic welding. A single machine can weld dozens to hundreds of culture bottles per minute, significantly increasing production capacity. Automated operation reduces manual intervention, significantly reducing labor costs.

2. Precise welding, strong sealing: adopting precision positioning and welding control system to ensure uniform and firm welding. High consistency of weld, eliminating leakage and loosening phenomenon, guaranteeing the sealing of culture bottles. Online detection function eliminates defective products and ensures the qualified rate of welding.

3. Automatic control, easy to operate: equipped with PLC control and touch screen interface, adjustable parameters, easy to operate. Programmable control, adapt to different bottle types and specifications, strong flexibility. Fault automatic alarm and shutdown protection, easy maintenance.

4. High welding stability, high yield: automatic welding machine welding parameters are stable and controllable, welding quality is uniform. Product consistency is high, and the pass rate is stable above 98%. Adaptable to batch production and multi-specification culture bottle manufacturing.

With high efficiency, precise welding and automatic operation, the automatic welding machine for culture bottles has become an indispensable equipment in the field of biopharmaceutical and laboratory equipment production. It can not only significantly improve the production efficiency, but also to ensure the welding quality and sealing, to meet the mass production and high quality requirements. In the future, with the continuous development of intelligent manufacturing and automation technology, culture bottle automatic welding machine will play a more important role in the field of biopharmaceuticals, medical devices and laboratory equipment.