Release Date:2025-03-26 14:33:04 Popularity:

With the rapid development of the medical industry, the demand for syringes, as one of the most common medical devices in clinical diagnosis and treatment, continues to grow. Traditional syringe production and assembly mostly rely on manual or semi-automatic equipment, low efficiency and easy to exist pollution hidden danger. As a modern equipment integrating automation, precision and high efficiency, syringe automatic assembly machine can realize automatic assembly, testing and packaging of syringe parts, greatly improve production efficiency, ensure product quality, and meet the strict requirements of the medical industry for sterility, safety and efficiency.

I. Working principle and structure of syringe automatic assembly machine

1. The syringe automatic assembly machine adopts mechanical transmission, pneumatic system and intelligent control technology to automate the assembly and testing of syringe components (such as syringe, needle, piston, push rod, etc.). Its workflow is as follows:

Feeding and supplying: the equipment automatically feeds the various components of the syringe (such as syringe, piston, push rod, etc.) into the working area through the automatic feeding device.

Automatic positioning and assembly: The syringe barrel and piston are automatically aligned by precision robot or feeding rail. The piston and push rod are automatically inserted and assembled to ensure sealing and smoothness.

Sealing and Inspection: After assembling the parts, the equipment automatically inspects the assembly precision and sealing. Unqualified products will be rejected automatically.

Finished product collection and packaging: qualified syringes enter the automatic packaging line for sterilization, encapsulation or labeling.

2. The syringe automatic assembly machine usually consists of the following core parts:

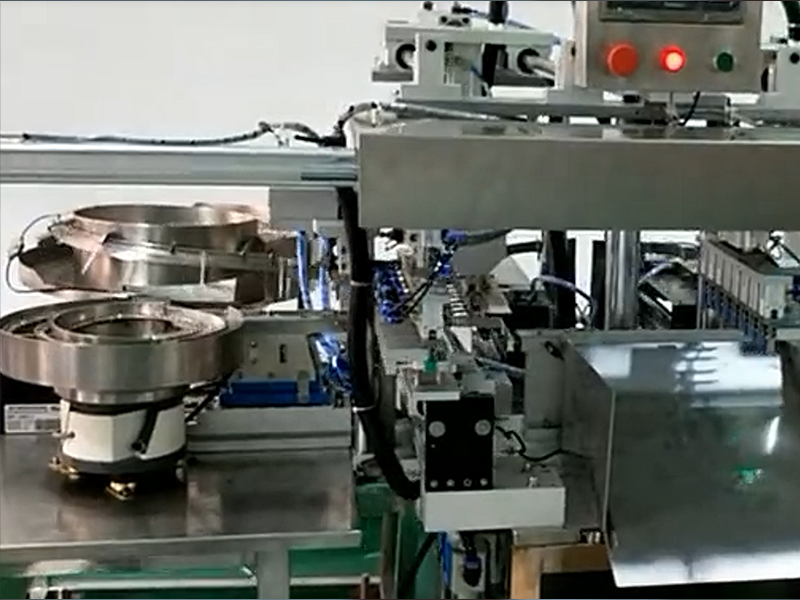

Automatic feeding system: including vibrating plate, loading conveyor or manipulator to realize automatic loading and feeding.

Assembly module: including automatic assembly processes such as needle loading, push rod loading, piston loading and sealing to ensure assembly precision.

Detection and rejection system: equipped with visual detection and sensor detection devices, real-time monitoring of assembly quality.

Control system: PLC or industrial computer control is adopted to realize automatic operation and parameter adjustment.

Receiving and packaging system: the qualified products will be automatically collected or enter the packaging process to improve the degree of automation.

Second, the advantages of syringe automatic assembly machine

1. High-efficiency automated production: the syringe automatic assembly machine can realize 24-hour continuous operation, the production efficiency is much higher than manual or semi-automatic equipment. The production capacity can reach 500-1500 pcs per hour, which greatly improves the production efficiency. Realize automatic assembly, automatic inspection and automatic packaging without manual intervention.

2. High assembly precision and stable product quality: the automatic assembly machine adopts servo motor and precision positioning system to ensure assembly precision. The assembly error is controlled within ±0.1mm, which can effectively guarantee the sealing and safety of the syringe. The equipment is equipped with online detection and rejection system, which can automatically reject the substandard products and guarantee the quality of the factory.

3. Aseptic production, in line with medical standards: the equipment operates in a clean workshop, in line with GMP (Good Manufacturing Practice) requirements. Component assembly adopts non-contact automatic assembly, reducing the risk of contamination. Finished products can be automatically sterilized and packaged to ensure product sterility.

4. Saving labor and production costs: an automatic assembly machine can replace 5 to 10 manual workstations, significantly reducing labor costs. Reduce manual intervention, reduce human error and contamination risk. Significantly increase production capacity and yield, shorten the production cycle.

5. Strong flexibility and compatibility: the automatic assembly machine is compatible with the production of syringes of different specifications (such as 1ml, 3ml, 5ml, 10ml, etc.). The modularized design of components can quickly switch production specifications and adapt to diversified needs. It can be integrated with automatic filling, automatic labeling and packaging equipment to realize a complete automated production line.

Points to choose and buy syringe automatic assembly machine

1. Production efficiency and capacity to match: according to the production demand to choose the production speed per minute and capacity of the appropriate equipment. Capacity should meet current and future production needs.

2. Assembly accuracy and detection function: the equipment should be equipped with high-precision assembly and detection system to ensure product qualification rate. Detection accuracy is required to be controlled within ± 0.1mm.

3. Stability and maintenance of equipment: choose the stable structure, smooth operation of the equipment, reduce downtime maintenance time. Maintenance is simple, easy to replace parts.

4. Brand and after-sales service: choose a well-known brand and reliable after-sales service to ensure long-term stable operation of the equipment. Timely after-sales service, provide technical support and spare parts protection.

With the advantages of high efficiency, precision, automation and sterility, the syringe automatic assembly machine plays an important role in the medical device manufacturing industry. It not only significantly improves production efficiency and guarantees product quality, but also reduces production costs and labor input. In the future, with the development of intelligent and flexible manufacturing technology, the syringe automatic assembly machine will move in the direction of more efficient, intelligent and green, helping the medical device industry to achieve higher quality production standards.