Release Date:2025-03-25 15:16:50 Popularity:

In the field of modern industrial manufacturing, chamfering process is an important link to improve the precision and aesthetics of products. Automatic chamfering machine, as a kind of automatic equipment specially used for chamfering workpiece edges, corners or orifices, is widely used in metal processing, mold manufacturing, mechanical parts, pipe processing and other industries. Compared with the traditional manual chamfering or semi-automatic equipment, the automatic chamfering machine has the advantages of high efficiency, high precision, easy operation, strong stability, etc., which can significantly improve production efficiency and product quality.

First, the working principle and structure of automatic chamfering machine

1. Working principle, automatic chamfering machine using high-speed rotary tool or grinding wheel, the edge of the workpiece for trimming, deburring and chamfering. Its workflow usually includes:

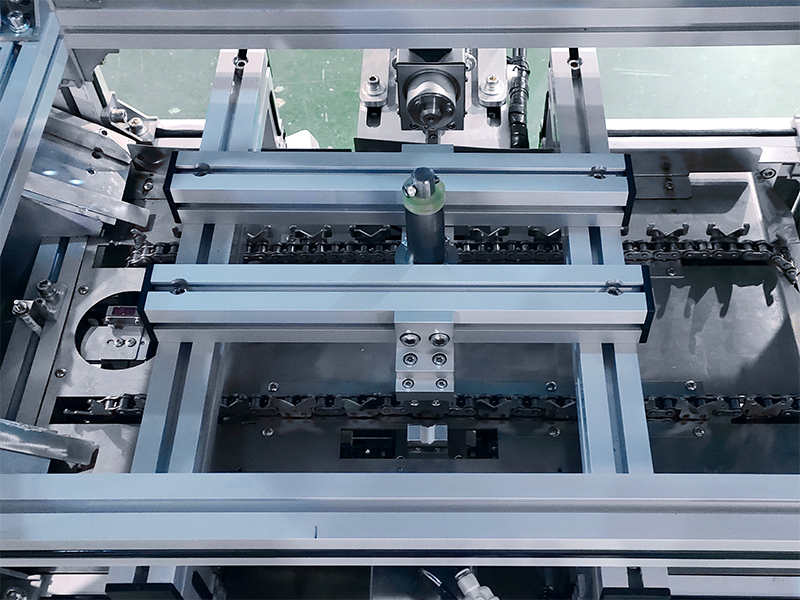

Automatic feeding of workpieces: the workpieces are fed into the machining area by automatic conveyor belt or manipulator.

Automatic positioning and clamping: the machine automatically positions the workpiece and clamps it with hydraulic or pneumatic fixtures to ensure machining stability.

Chamfering: High-speed rotating tools or grinding wheels chamfer the workpiece to ensure smooth edges and consistent precision.

Automatic inspection and discharging: the equipment is equipped with automatic inspection and sorting function to ensure that the finished products are sent out after the processing precision is qualified.

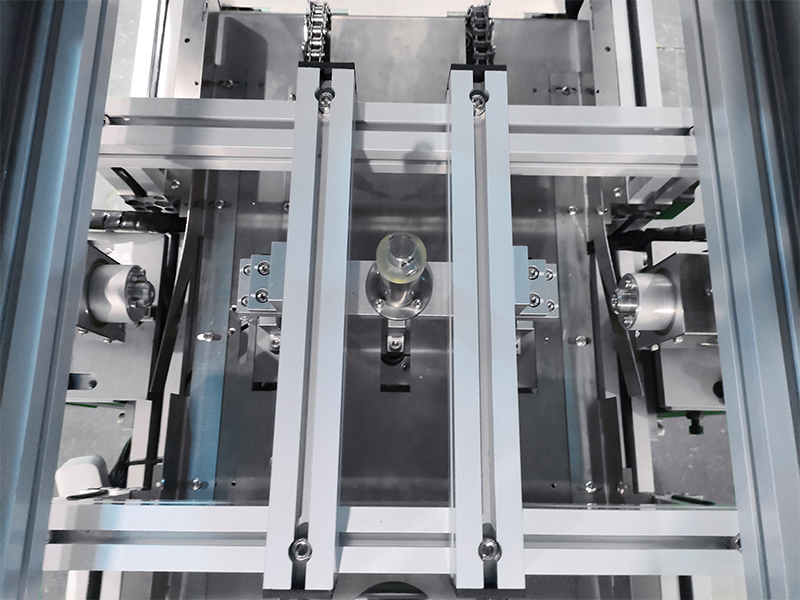

2. Composition of equipment structure, automatic chamfering machine usually consists of the following major components:

Main frame and machine tool: solid frame and processing table to ensure smooth operation and no vibration.

Feeding and positioning system: automatic feeding device and precision positioning mechanism to ensure that the workpiece is accurately in place.

Chamfering cutter head or grinding wheel: adopting carbide cutter or diamond grinding wheel, rotating at high speed to complete the chamfering operation.

Numerical control or PLC control system: through the numerical control program or PLC control, realize automatic processing with adjustable parameters.

Cooling and dust removal system: automatic cooling of the tool during processing, and equipped with dust collection device to ensure a clean working environment.

Second, the advantages of automatic chamfering machine

1. Efficient automatic production: automatic chamfering machine adopts continuous feeding and processing mode, which can realize batch production. Fast processing speed, single piece of workpiece chamfering time can be controlled within 15 seconds. It can be integrated with automatic assembly line for unmanned production.

2. High chamfering accuracy and consistency: driven by CNC system or servo motor, the chamfering angle and depth accuracy can reach ±0.05mm, which ensures that the chamfering size of each workpiece is consistent and avoids manual processing errors. It can chamfer smooth, beautiful and burr-free edges.

3. Saving labor cost: the equipment realizes automatic feeding, clamping, chamfering and discharging, reducing manual intervention. One operator can manage multiple machines at the same time, saving labor costs. Processing efficiency increases, effectively reducing production costs and time.

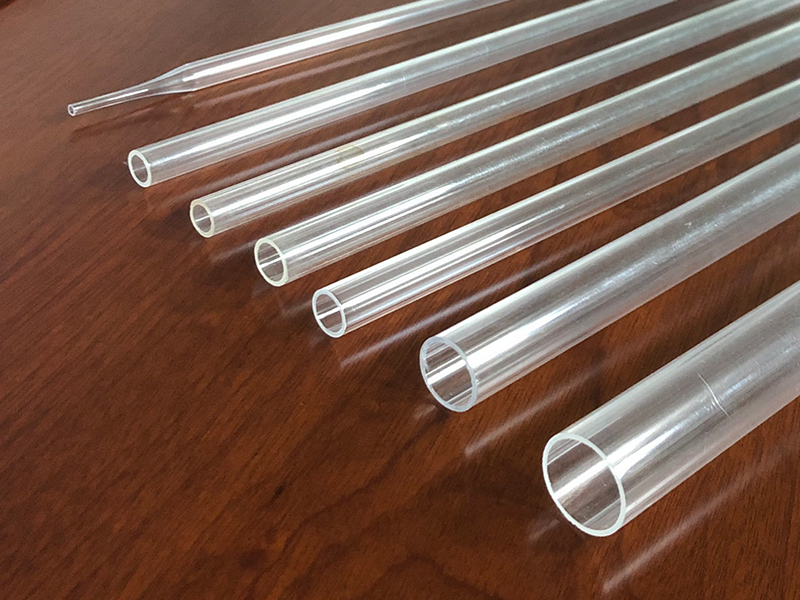

4. Multi-functional and flexible: chamfering can be carried out for workpieces of different materials and shapes, such as stainless steel, aluminum alloy, carbon steel, copper, plastic, composite materials and so on. It can realize chamfering of inner hole, outer edge, plane, bevel and other angles. The chamfering angle and size can be flexibly adjusted, suitable for diversified production needs.

5. High environmental protection and safety: the automatic chamfering machine is equipped with cooling and dust removal system, less dust in the processing, strong environmental protection. The operation is automated, reducing manual contact and safety hazards. Closed structure or protective cover is adopted during processing to prevent flying chips from hurting people.

Application areas of automatic chamfering machine

1. Metal processing industry: automatic chamfering machine is widely used in the edge processing of steel plates, profiles, pipe fittings. Chamfering the outer corners, inner holes or weld seams of metal parts, removing burrs and improving welding quality. In the automotive parts, hardware tools, aerospace and other fields are used in large quantities.

2. Mold and machinery manufacturing: In mold manufacturing, automatic chamfering machine is used for mold edge trimming to ensure smooth mold surface. Mechanical parts processing, through the automatic chamfering machine for deburring and rounding processing, improve the assembly precision.

3. Pipes and tubes industry: automatic chamfering machine is used for chamfering the mouth of metal pipes and plastic pipes to ensure that there is no burr and no jamming when welding or assembling. Commonly used in water pipes, gas pipes, oil pipes and other pipe processing.

4. Automobile manufacturing and maintenance: Automobile manufacturing field has high requirements for parts chamfering, such as piston rods, crankshafts, brake pads and other workpieces chamfering. Automatic chamfering machine can improve parts processing accuracy and reduce assembly resistance.

Fourth, the main points of automatic chamfering machine purchase

1. Processing accuracy and stability: Select high-precision tools and servo motors to ensure stable chamfering accuracy. Processing error should be controlled within ± 0.05mm.

2. Degree of automation: choose fully automatic feeding, processing and discharging equipment, suitable for mass production. The equipment should have automatic detection and abnormal alarm function.

3. Processing materials and specifications: according to the processing material (such as steel, aluminum alloy or plastic) to choose the right tool. Ensure that the equipment is suitable for large quantities and multi-specification workpiece processing.

4. Brand and after-sales service: choose a well-known brand and high-quality after-sales service to ensure the long-term stable operation of the equipment.

Automatic chamfering machine plays an important role in metal processing, machinery manufacturing, pipe processing and other fields by virtue of its high efficiency, precision and automation processing capability. It can significantly improve production efficiency, reduce labor costs, and ensure product processing accuracy and aesthetics. In the future, with the continuous development of intelligent and automation technology, the automatic chamfering machine will realize a wider range of applications in more fields, helping industrial manufacturing to efficient, precise and green direction.