Release Date:2025-03-14 14:05:09 Popularity:

With the rapid development of the global manufacturing industry and the arrival of the intelligent manufacturing era, the fully automated production line has become the core driving force of modern industrial production. It completes the whole process automation operation from raw material conveying, processing, testing, packaging to finished product output through robots, intelligent control system, data analysis, artificial intelligence (AI) and other advanced technologies, which significantly improves the production efficiency, reduces the cost, and ensures the stability of product quality.

First, the working principle of fully automated production line

The fully automated production line is mainly composed of automatic feeding system, intelligent processing equipment, robot operating system, intelligent detection devices, data management system and other components, its workflow is as follows:

1. Automatic conveying of raw materials: adopting conveyor belt, manipulator and AGV (Automatic Guided Vehicle) to realize the automatic transmission of raw materials.

2. Intelligent processing and assembly: complete product manufacturing and assembly by CNC machining centers, 3D printing equipment, automatic welding robots and other high-precision equipment.

3. Quality inspection and optimization: Combining machine vision, X-ray inspection, AI intelligent analysis and other technologies to ensure that the quality of each process meets the standards.

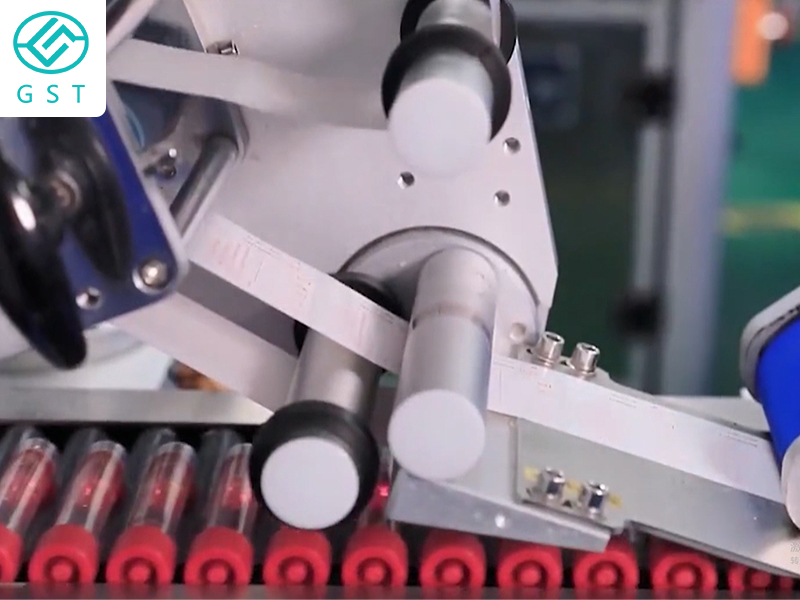

4. Automatic Packaging and Labeling: Finished products are packaged, labeled and classified through automatic packaging machines, inkjet printers and barcode printing systems.

5. Intelligent warehousing and logistics: adopting automatic sorting system, intelligent three-dimensional warehouse and unmanned truck to realize efficient warehousing and logistics management.

6. Data monitoring and remote management: through industrial Internet (IIoT) and cloud computing, realize remote monitoring, intelligent diagnosis, real-time analysis of production data.

Second, the core advantages of fully automated production line

1. Enhance production efficiency: 24-hour continuous operation, production efficiency is 35 times higher than traditional manual operation.

2. Reduce labor costs: the traditional production line requires a large number of workers to operate, while the fully automated production line reduces the dependence on labor, reducing the operating costs of enterprises.

3. Improve the stability of product quality: the use of intelligent detection systems and standardized operations to ensure stable product quality and reduce human error.

4. Optimize the use of resources and reduce production costs: precisely control the use of raw materials, reduce waste and improve production efficiency.

5. Flexible production, adapt to the needs of multiple varieties: modern fully automated production line supports flexible manufacturing, which can quickly switch production mode and adapt to different specifications and models of products.

6. Data intelligence, real-time monitoring: through cloud data analysis, AI predictive maintenance, timely detection of production anomalies, improve equipment life.

7. Enhancement of safety: Adoption of intelligent protection system and machine self-checking function reduces the risk of workers involved in high-risk operations and enhances production safety.

Application areas of fully automated production line

1. Food and beverage industry: automated packaging, filling, encapsulation, sterilization, sorting, enhance food safety and production efficiency.

2. Pharmaceutical and medical device industry: automated pharmaceutical, aseptic packaging, intelligent detection, to ensure that the quality of drugs in line with GMP standards.

3. Electronics and semiconductor manufacturing: SMT mounter, automatic assembly, precision testing, to ensure high precision and stability of electronic component production.

4. Automobile manufacturing industry: robot welding, automatic spraying, assembly line, to enhance the intelligence of automobile manufacturing.

5. Chemical and new energy industry: automated reaction control, intelligent feeding, unmanned production, to ensure that the production process is safe, environmentally friendly and efficient.

6. Logistics and warehousing management: automatic sorting system, AGV handling, intelligent warehousing system, improve the accuracy and efficiency of logistics and distribution.

Fourth, the future development trend of fully automated production line

1. Artificial Intelligence-driven intelligent manufacturing: in the future, AI will be deeply integrated into the fully automated production line to achieve intelligent optimization of scheduling, independent learning troubleshooting, intelligent adjustment of production processes to further improve production efficiency and quality.

2. Integration of Industrial Internet of Things (IIoT) and 5G technology: Through 5G+Industrial Internet, real-time transmission of production data, remote monitoring and cloud management will be realized to improve the response speed and management capability of smart factories.

3. Flexible manufacturing and customized production: the future production line will be more flexible and adaptive, and can quickly adjust the production mode according to the order demand to achieve large-scale personalized customization.

4. Green and energy-saving technologies: Low-energy equipment, recyclable materials, and energy-saving control systems are used to facilitate low-carbon manufacturing and reduce carbon emissions from industrial production.

5. Human-machine collaboration mode: the future fully automated production line will pay more attention to the collaboration between people and intelligent equipment, the use of collaborative robots (Cobots), to enhance the flexibility and safety of production.

6. Globalized market competition: With the development of automation technology, more and more companies will invest in the construction of fully automated production lines to take the lead in the global market competition.

Fully automated production line is not only a key means to improve the efficiency of modern industrial production, but also an important part of the future intelligent manufacturing and industry 4.0 era. It improves production efficiency, reduces costs, optimizes product quality, and promotes industries to a new stage of intelligent manufacturing through intelligence, data, and unmanned. In the future, with the in-depth development of AI, 5G, industrial IoT and other technologies, the fully automated production line will be further intelligent, bringing broader prospects for the innovation and development of the manufacturing industry.