Release Date:2025-03-13 14:47:21 Popularity:

In the context of accelerated transformation and upgrading of the global manufacturing industry, automation equipment manufacturers have become a key force in promoting industrial production intelligence, efficiency improvement and cost optimization. Automation equipment is widely used in food, medicine, electronics, packaging, automotive, chemical and other industries, through robots, intelligent control systems, sensing technology and other means to realize the automation of the production process, intelligent, unmanned, and greatly improve production efficiency and product quality. This article will explore the role of automation equipment manufacturers, the current state of the industry, core competitiveness and future development trends.

First, the current situation of the industry of automation equipment manufacturers

With the rapid advancement of Industry 4.0 and intelligent manufacturing, the global manufacturing industry is moving towards a high degree of automation, and the market demand for automation equipment manufacturers continues to climb. At present, the automation equipment industry mainly presents the following characteristics:

1. Strong market demand, wide range of application industries: automation equipment is widely used in food packaging, pharmaceutical production, 3C electronics manufacturing, automotive assembly, logistics sorting, intelligent warehousing and other fields, the market outlook is broad.

2. Rapid development of intelligent technology: modern automation equipment integrated PLC control system, industrial robots, artificial intelligence (AI), Internet of Things (IoT), big data analysis and other high-tech to achieve intelligent production.

3. Increased demand for personalized customization: Due to the different automation needs of various industries, more and more manufacturers provide customized automation solutions to meet the specific needs of enterprises.

4. Industry cluster effect is obvious: China, Germany, Japan, the United States as the representative of the major manufacturing countries, the formation of automation equipment industry clusters, promoting the development of industry scale.

Second, the core competitiveness of automation equipment manufacturers

In order to take the lead in the fierce market competition, automation equipment manufacturers need to have the following core competencies:

1. Technical R & D capabilities: a strong technical research and development team, continuous innovation, development of high-precision, high-stability, highly intelligent automation equipment. Combined with artificial intelligence (AI), big data, 5G communications, Internet of Things (IoT) and other cutting-edge technologies, to achieve intelligent upgrading.

2. Product quality and stability: Adopt high-quality materials and advanced processing technology to ensure stable and durable equipment operation and improve customer satisfaction. The equipment should comply with international standards such as ISO quality management system, CE certification and GMP standards to ensure market competitiveness.

3. Customized solutions: Provide personalized automated production lines and equipments to meet the production needs of different enterprises, and improve customers' production efficiency and product quality.

4. After-sales service system: provide remote diagnosis, online technical support, regular maintenance and other one-stop services to ensure long-term stable operation of equipment.

5. Cost control and production efficiency: through optimization of production processes, refined management, supply chain integration, reduce production costs and improve market competitiveness.

6. Brand influence: through technological innovation and marketing, to create a well-known brand in the industry, improve market share and customer recognition.

Third, the main application industries of automation equipment manufacturers

1. Food industry: produce automatic packaging machines, filling machines, sealing machines, conveying equipment, etc., to improve food production efficiency and safety.

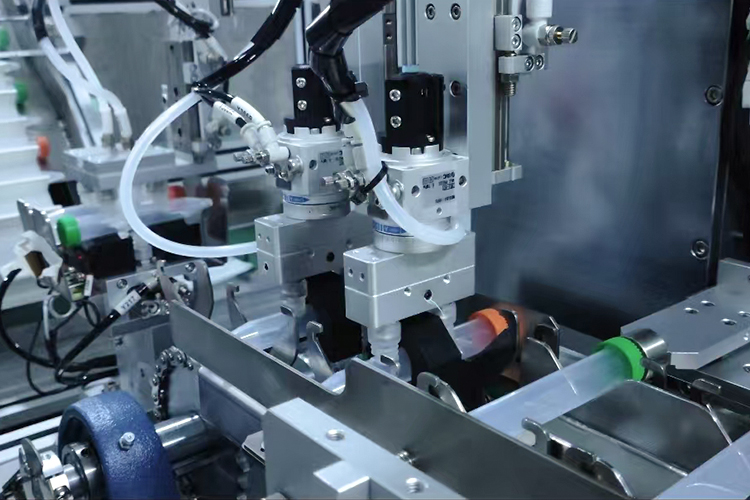

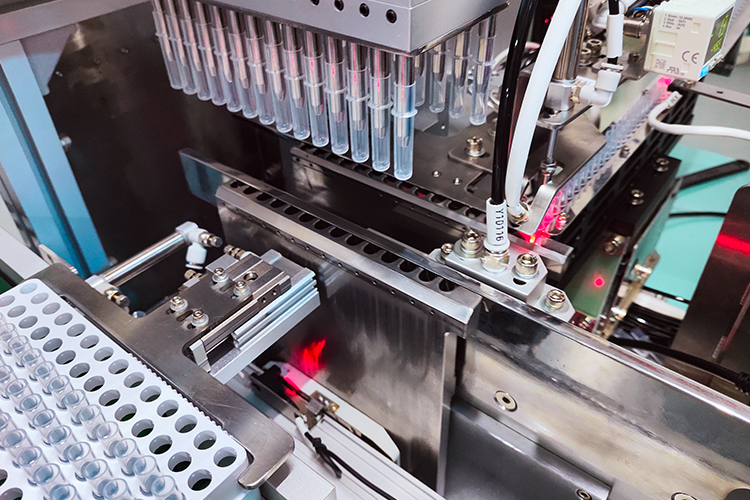

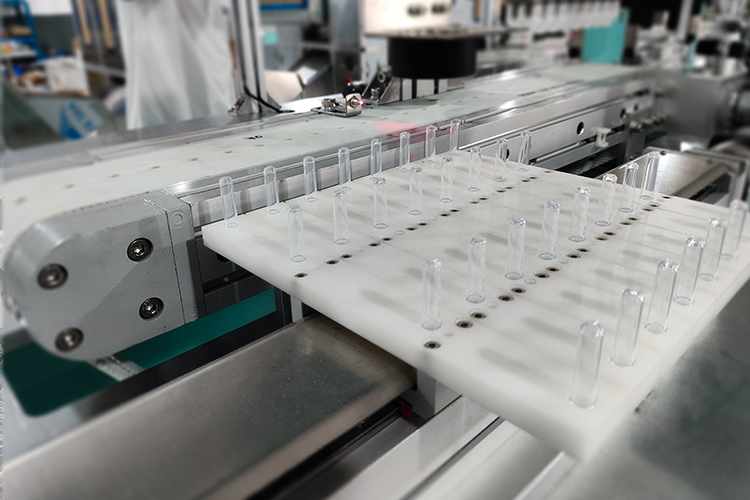

2. Pharmaceutical industry: provide intelligent pharmaceutical equipment, automatic filling machines, aseptic packaging machines, in line with GMP standards, to improve pharmaceutical safety.

3. Electronic industry: develop SMT mounter, electronic component assembly equipment, robot welding, improve the production accuracy and efficiency of electronic products.

4. Automobile manufacturing industry: adopt robot assembly, laser welding, intelligent inspection system to improve the intelligent level of automobile production.

5. Intelligent logistics and warehousing: the development of automatic sorting system, unmanned handling robots (AGV), three-dimensional warehouse, improve logistics efficiency and warehousing intelligence.

Fourth, the future development trend of automation equipment manufacturers

1. Intelligent upgrading: future automation equipment will be further integrated into AI, IoT, cloud computing, digital twins and other technologies to achieve intelligent monitoring of equipment, autonomous optimization, adaptive production.

2. Flexible production: the equipment will have stronger adaptability to support the rapid switching of different products, improve the degree of production flexibility, and adapt to the needs of multi-species, small batch production.

3. Green manufacturing and energy saving and environmental protection: the use of low energy consumption drive system, recyclable materials, reduce energy consumption, and promote the development of green manufacturing.

4. Human-machine collaboration and safety optimization: future automation equipment will pay more attention to human-machine collaboration, equipped with intelligent sensing systems, improve production safety and reduce the risk of worker operation.

5. Global market expansion: automation equipment manufacturers will accelerate the layout of the international market, enhance global competitiveness, and promote the development of intelligent manufacturing globalization.

Automation equipment manufacturers are the core force to promote intelligent manufacturing, improve production efficiency and reduce manufacturing costs. With the progress of science and technology, automation equipment is developing in the direction of intelligent, flexible and green, providing more advanced and efficient automated production solutions for various industries. In the future, automation equipment manufacturers will continue to make efforts in technological innovation, product optimization, intelligent manufacturing, etc., to provide strong support for the upgrading of the global manufacturing industry, and help enterprises to move towards a more efficient and smarter future.