Release Date:2025-02-14 15:07:28 Popularity:

In the field of modern industrial manufacturing, standardized equipment has been unable to meet the special production needs of all enterprises. Therefore, non-standard equipment manufacturing has become an important choice for many industries to improve production efficiency and optimize process flow. Non-standard equipment refers to non-universal automation equipment designed and manufactured according to specific production requirements, combined with process characteristics. With the development of science and technology and changes in market demand, the non-standard equipment manufacturing industry is ushering in new development opportunities.

The characteristics of non-standard equipment manufacturing

1. Customized design: the core feature of non-standard equipment manufacturing is customized according to customer needs to ensure that the equipment can be adapted to the production process of a particular product. For example, food processing, automotive parts production, electronic component assembly and other industries, often require highly accurate and specially designed production equipment to meet their unique processing needs.

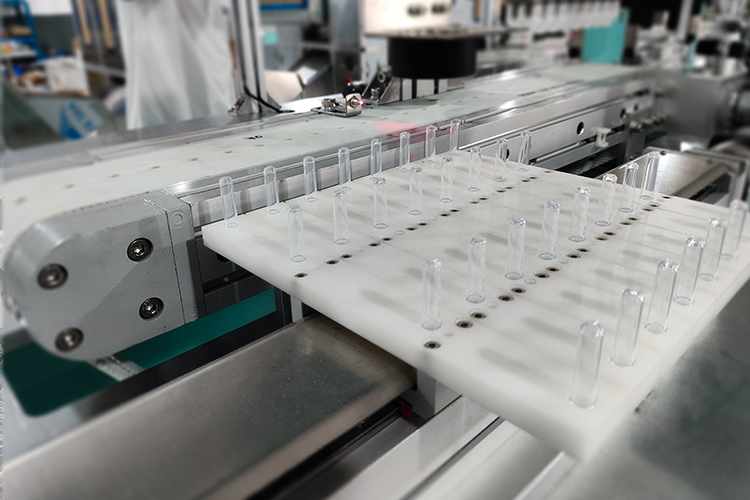

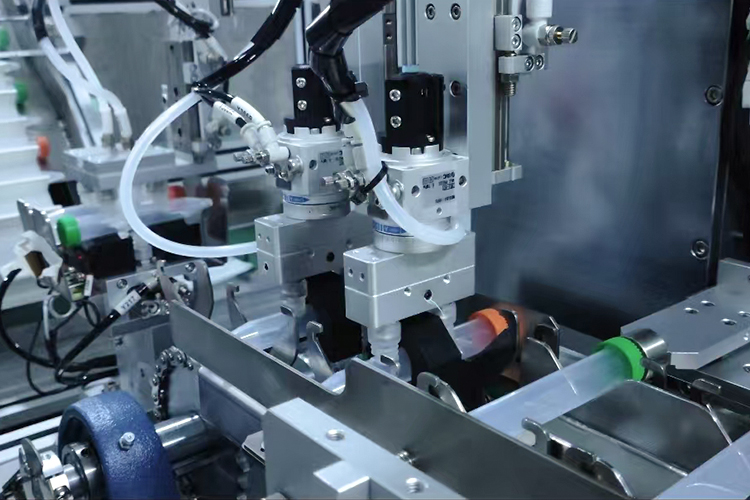

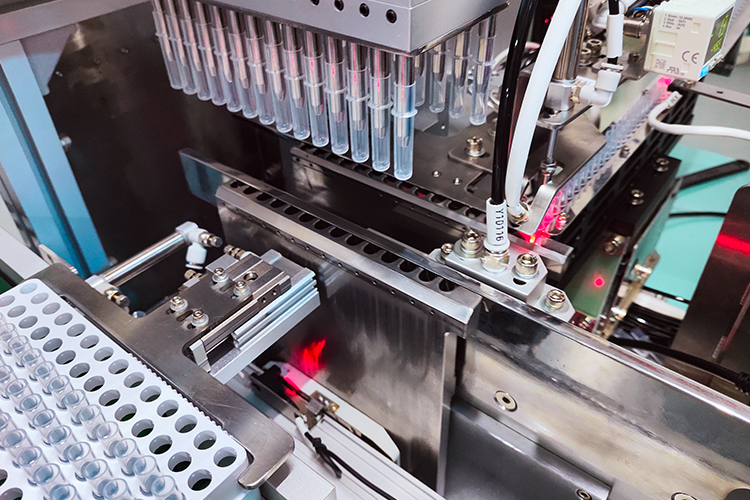

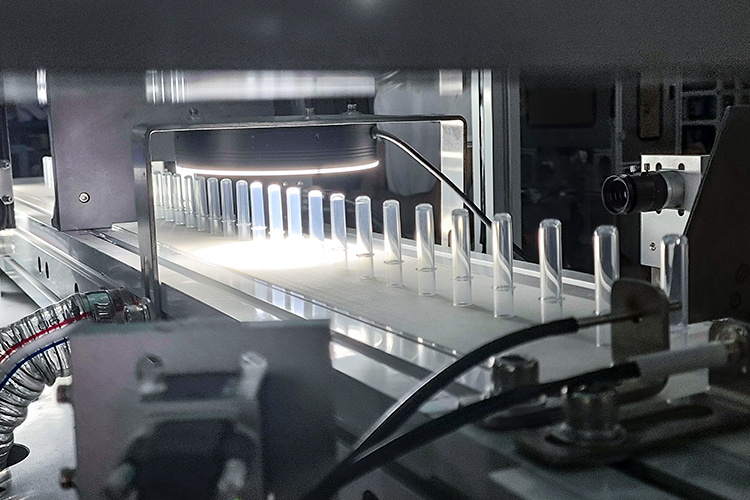

2. Highly automated: modern non-standard equipment is widely used in intelligent control systems, combined with sensors, PLC (Programmable Logic Controller), robotics and other advanced technologies to achieve intelligent and automated production. This not only reduces manual intervention, but also improves production efficiency and product quality.

3. Flexibility: unlike standardized equipment, non-standard equipment has a higher degree of flexibility, and can be adjusted for different product types and production requirements. For example, a non-standard automated production line can be compatible with a variety of specifications of product packaging, without the need for frequent replacement of equipment, thereby reducing the operating costs of enterprises.

4. High technical difficulty: As each non-standard equipment needs to be based on customer demand for a new design and manufacturing, which involves a high degree of technical difficulty, often requiring multi-disciplinary expertise, such as mechanical design, electronic control, automation system integration. Therefore, non-standard equipment manufacturers with strong R & D capabilities in the industry competition is more advantageous.

Application areas of non-standard equipment manufacturing

1. Automotive manufacturing industry: the production and assembly of automotive parts and components require highly accurate non-standard automation equipment, such as engine assembly lines, welding robots, intelligent testing equipment, etc., to ensure product quality and production efficiency.

2. Food and beverage industry: non-standard equipment in food processing, packaging and testing play an important role. For example, for different food forms (solid, liquid, paste, etc.) designed filling machines, automatic labeling machines, sealing machines and other equipment, are non-standard equipment category.

3. Electronic manufacturing industry: in the field of electronic components production, non-standard equipment can be used for precision welding, automatic assembly, dispensing, testing and other aspects of the production to improve accuracy and reduce manual errors.

4. Medical device industry: medical device manufacturing involves strict production standards and health requirements, non-standard automation equipment can ensure that the products comply with industry regulations and improve production safety. For example, reagent filling equipment, drug packaging machine, sterile production line, etc..

The future development trend of non-standard equipment manufacturing

1. Intelligent and digital: with the development of artificial intelligence and industrial Internet of Things (IIoT), the future of non-standard equipment will be more intelligent, able to achieve remote monitoring, data analysis, automatic fault diagnosis and other functions to improve the efficiency of equipment operation and maintenance.

2. Combination of modularization and standardization: Although non-standard equipment is mainly customized, the future development trend is to standardize some of the functional modules to improve the versatility and scalability of the equipment, in order to reduce manufacturing costs and delivery cycle.

3. Green design: modern industrial requirements for environmental protection is becoming increasingly high, non-standard equipment manufacturing also need to move towards the direction of energy saving, environmental protection. For example, the use of energy efficient motors, reduce material waste, optimize energy management.

Non-standard equipment manufacturing industry plays a vital role in the process of industrial automation. It can not only meet the individualized production needs of enterprises, but also promote the manufacturing industry to the intelligent, flexible and efficient direction. In the future, with the continuous progress of science and technology, non-standard equipment manufacturing will further improve production efficiency, helping enterprises to occupy a favorable position in the fierce market competition.