Release Date:2025-02-17 15:28:35 Popularity:

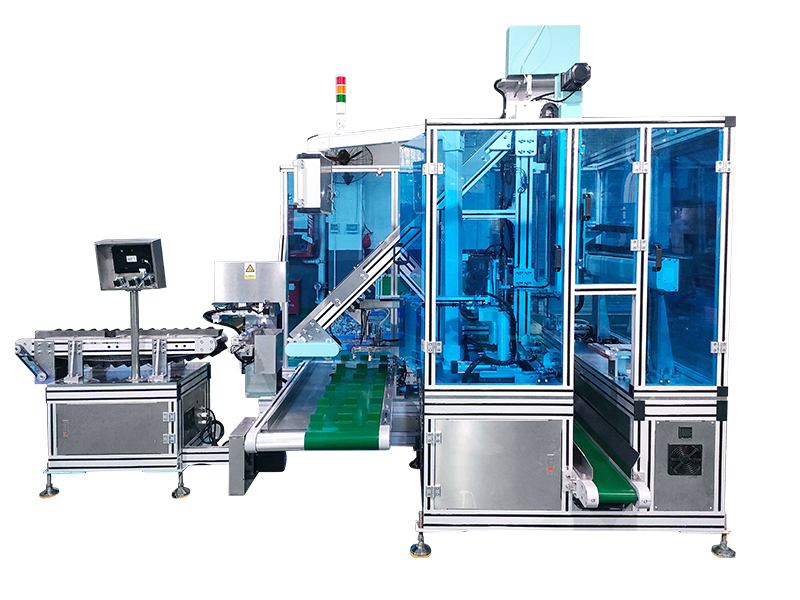

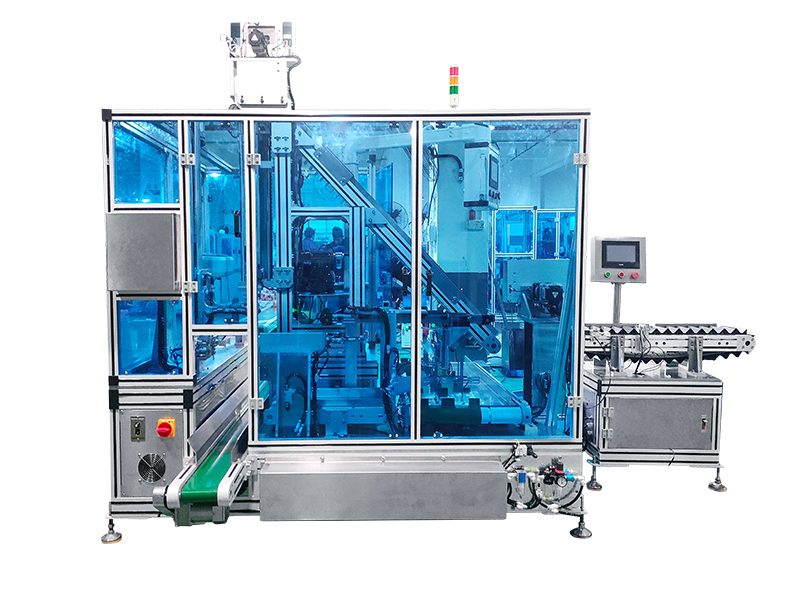

Automatic Bag Packing Machine is a highly automated packaging equipment widely used in many industries such as food, medicine, chemical industry, etc. Especially in the packaging of bulk commodities, granules, powders, liquids as well as small products, it has the significant advantages of high efficiency, precision and intelligence. This kind of equipment can automatically form, fill, seal and output the pre-made bags, which greatly improves the production efficiency, reduces the labor cost, and ensures the stability and consistency of the packaging. In this paper, we will discuss in detail the working principle, characteristics, application areas and future development trend of automatic bag packaging machine.

First, the working principle of automatic bag packaging machine

Automatic bag packaging machine working principle based on the combination of mechanical and automation technology, mainly includes the following processes:

1. Bag piece feeding and molding: first of all, the pre-prepared bags from the automatic bag feeding system to the equipment work position. The equipment positions and shapes the bag pieces according to the specifications and size requirements of the bag and opens the bag opening.

2. Material Filling: Once the bag is positioned, the automated filling system begins to accurately fill the bag with material according to the set metering method. The way of filling material can be chosen according to the product characteristics such as liquid filling, granule filling, powder filling and so on.

3. Sealing: After the filling is completed, the equipment will automatically seal the opening part of the bag, common sealing methods include heat sealing, pressure sealing and so on. The sealing system, through high temperature or pressure, makes the bag mouth firmly sealed to prevent material leakage or external pollution.

4. Output and Cutting: After the sealing is completed, the equipment will discharge the bags and cut the finished products according to the needs of the production line to ensure that the size of each bag is consistent.

This workflow is coordinated through the PLC control system, and the equipment operator only needs to set the parameters and carry out simple monitoring, thus realizing fully automatic operation.

Second, the characteristics of automatic bag packaging machine

1. High efficiency and automation: automatic bag packaging machine can be uninterrupted packaging, improve production efficiency. Its high degree of automation, basically reducing the manual operation, reducing labor intensity.

2. Accurate metering: the equipment can accurately control the filling amount according to the type and weight requirements of materials. Through high-precision sensors and metering devices, it ensures that the weight of materials in each bag is the same, avoiding too much or too little packaging and reducing waste.

3. Multi-functional adaptability: automatic bag packing machine has strong adaptability, can adapt to different specifications and different types of bags, to meet the diversified needs of customers for packaging forms and bag types. At the same time, the equipment can handle liquid, powder, granules and other materials, with a certain degree of flexibility.

4. Compact design and space-saving: the design of modern automatic bag packing machine is usually very compact and covers a small area. This makes it easy to be embedded into production lines of different sizes, saving space in the production site and improving productivity.

5. Easy to clean and maintain: The equipment is made of food-grade stainless steel and other corrosion-resistant materials, which ensures the hygiene and safety of the packaging process. The structure of the equipment is simple, easy to clean, in line with the high standards of modern production on health and safety.

Third, the application field of automatic bag packaging machine

Automatic bag packing machine is suitable for a variety of industries, especially in the packaging process requires high efficiency, high precision, low labor costs in a wide range of fields. The following are its main application areas:

1. Food industry: the food industry is one of the most widely used automatic bag packaging machine. The equipment can be used to package candy, nuts, seasonings, dried fruits, rice, noodles and many other foods. Automatic bag packaging machine can not only improve the packaging efficiency, but also to ensure the hygiene and consistency of food packaging, in line with the strict standards of the food industry.

2. Pharmaceutical industry: the pharmaceutical industry has very high requirements for packaging quality and hygiene. Automatic bag packing machine is suitable for pharmaceutical packaging, especially for granules, tablets, capsules and powders. It can be operated in aseptic environment to ensure the precision and safety of packaging.

3. Chemical industry: granules, powders and other materials in the chemical industry often need precise packaging. Automatic bag packing machine can quickly and efficiently complete the packaging of chemical products to ensure packaging accuracy and product quality, while avoiding material contamination and leakage.

4. Daily chemical industry: in the daily chemical industry, laundry detergent, cosmetics, shampoo and other liquid or powder goods packaging often rely on automatic bag packaging machine. Equipment can provide different specifications and different forms of packaging to meet the diverse needs of consumers.

Fourth, the future development trend of automatic bag packaging machine

1. Intelligent development: with the development of intelligent technology, automatic bag packaging machine will gradually achieve a higher level of intelligence, through big data and Internet of Things technology to real-time monitoring of the operating state of the equipment, automatically adjust the packaging parameters, and further improve packaging efficiency and quality.

2. Environmental protection and energy saving: with the increasing requirements of environmental protection and energy saving, the future of automatic bag packaging machine will be more green materials and energy-saving technologies to reduce energy consumption, reduce the generation of packaging waste, to achieve sustainable development.

3. Higher versatility and flexibility: the future of automatic bag packaging machine will pay more attention to multifunctionality, can adapt to more types and specifications of packaging needs. The design of the equipment will be more flexible, able to quickly adjust and adapt to different production tasks to meet the diverse needs of the market.

With its high efficiency, precision and automation, fully automatic bag packaging machine has been widely used in many industries, especially in the fields of food, medicine, chemical and daily chemicals, and has become an important tool to improve production efficiency and reduce labor costs. With the progress of technology, automatic bag packaging machine will continue to develop in the direction of intelligence, environmental protection and flexibility, bringing productivity improvement and cost optimization for more enterprises, and helping them to stand out in the fierce market competition.