Release Date:2025-02-10 16:09:32 Popularity:

With the development of industrial automation, automatic filling machine production line is widely used in many industries such as food, beverage, pharmaceutical, chemical, daily chemical and so on. It can realize efficient filling, encapsulation, labeling and other processes of materials, greatly improving production efficiency and reducing labor costs. However, there are large differences in the price of automatic filling machine production line on the market, different brands, models, functional configurations will have an impact on the price. In this paper, we will explore the price of automatic filling machine production line factors, and provide purchase guide to help enterprises make reasonable decisions in the procurement.

First, the main components of automatic filling machine production line

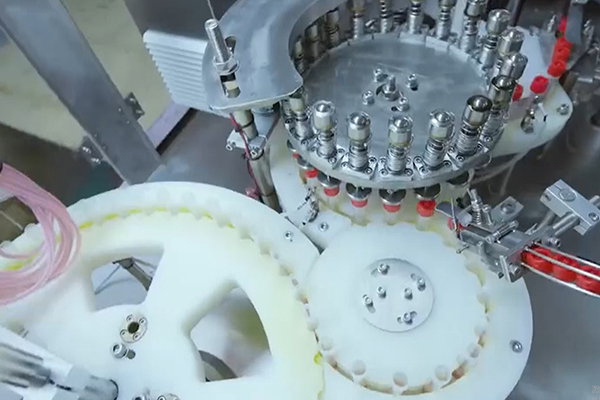

Automatic filling machine production line is usually composed of multiple automation equipment, including but not limited to:

1. Bottle handling machine: used to automatically organize and transport bottles to improve the automation level of the production line.

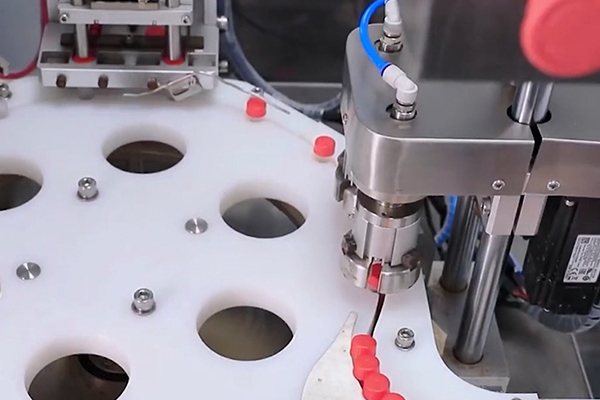

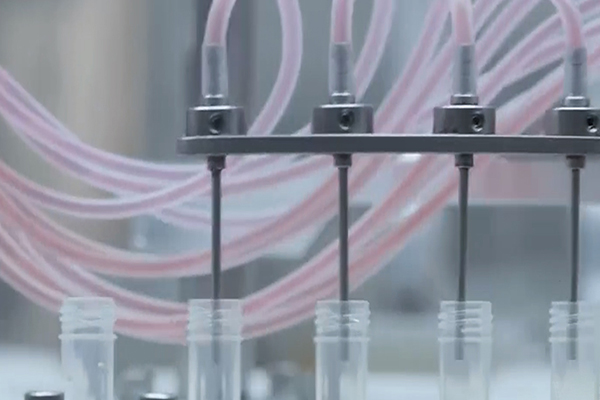

2. Filling machine: the core equipment, responsible for accurately filling liquid, powder or granule products into bottles or packaging containers.

3. Capping machine: sealing machine: automatically completes the screwing or encapsulation of bottle caps to ensure the sealing.

4. Labeling machine: automatically affix labels to provide product identification and improve package aesthetics.

5. Printing code machine: used to print production date, batch and other information, convenient for product traceability.

6. Conveying system: connecting each equipment to realize efficient assembly line operation.

These devices can be combined or customized according to the specific production needs of enterprises, so the price varies depending on the configuration.

Second, the main factors affecting the price of automatic filling machine production line

Automatic filling machine production line price depends on a number of factors, including the type of equipment, degree of automation, production capacity, material selection and so on.

1. Equipment type

According to the different filling materials, filling machine is divided into:

Liquid filling machine (for beverages, mineral water, alcohol, cosmetics, etc.)

Powder filling machine (for milk powder, flour, chemical powder, etc.)

Granule filling machine (suitable for candy, nuts, feed, fertilizer, etc.)

Different types of filling machines use different filling technologies, resulting in different prices. For example, powder filling machines usually require a sophisticated screw metering system, so the price may be higher than ordinary liquid filling machines.

2. Degree of automation

The higher the degree of automation of the automatic filling machine production line, the higher the price. The filling production line on the market is mainly divided into:

Semi-automatic filling production line (suitable for small and medium-sized enterprises, the price is lower)

Automatic filling production line (for large-scale production enterprises, the price is higher)

High degree of automation of the production line can realize unattended operation, reduce labor costs, improve production efficiency, so more favored by large-scale production enterprises.

3. Production capacity

The filling speed of the production line is usually calculated in bottles per hour (BPH). For example:

2000BPH production line is suitable for small and medium-sized enterprises

5000BPH or above production line is suitable for large-scale production enterprises

High-end lines above 10,000 BPH are usually more expensive.

The larger the production capacity, the higher the required filling accuracy and stability requirements, so the price of equipment is relatively higher.

4. Material and manufacturing process

Automatic filling machine production line is usually made of stainless steel (such as 304 or 316 stainless steel) to ensure hygiene standards in the food, pharmaceutical and other industries. 316 stainless steel is more corrosion-resistant than 304 stainless steel, so the price of equipment using high-end materials is also higher. In addition, precision processing technology and international brands of electrical components (such as Siemens PLC control system) will also affect the price.

5. Brand and after-sales service

Different brands of automatic filling machine production line prices vary greatly. Domestic brands are relatively low-priced, suitable for enterprises with limited budgets, while internationally renowned brands of equipment in terms of quality, stability and after-sales service is more advantageous, so the price is relatively higher. In addition, the supplier to provide installation and commissioning, technical support, maintenance and other after-sales service will also affect the final cost of the equipment.

Third, the price range of automatic filling machine production line

According to market conditions, the general price range of automatic filling machine production line is as follows:

Equipment type price range (RMB)

Semi-automatic filling production line: 50,000 to 200,000 yuan

Small and medium-sized automatic filling production line (20005000BPH): 200,000 to 500,000 yuan

Large automatic filling production line (500010000BPH): 500,000 to 1.5 million yuan

High-end customized production line (>10000BPH): more than 1.5 million yuan

Enterprises need to combine the production needs, budget and long-term return to make a reasonable choice when purchasing.

Fourth, how to choose the right automatic filling machine production line

1. Define the production demand: according to the production volume, product type, packaging specifications, etc., to determine the appropriate type of filling machine and production capacity.

2. Comparison of brands and suppliers: choose a reputable manufacturer, check customer cases, to understand its equipment performance and quality stability.

3. Examine the degree of automation: for large-scale production enterprises, it is recommended to choose high automation equipment to reduce manual intervention and improve production efficiency.

4. Focus on after-sales service: the stable operation of the equipment depends on good after-sales support, including installation and commissioning, training and routine maintenance.

5. Reasonable budget planning: comprehensively consider the price of equipment, long-term operating costs (such as energy consumption, maintenance costs) and return on investment to make the best decision.

The price of automatic filling machine production line is affected by a variety of factors, including the type of equipment, degree of automation, production capacity, materials, brands and so on. When purchasing, enterprises need to comprehensively consider the production demand, budget, automation degree and after-sales service, and choose the most cost-effective equipment. With the development of intelligent manufacturing, the future filling production line will be more efficient and intelligent, providing enterprises with better production solutions. Reasonable investment in a set of efficient filling production line can not only improve production efficiency, but also improve product quality and enhance market competitiveness.