Release Date:2025-03-31 16:13:27 Popularity:

In the fields of biomedicine, scientific research, experimentation and testing, pipette tips are widely used for dispensing, transferring and testing liquid samples as a common laboratory consumable. Due to the high demand for cleanliness and standardization of pipette tips, the traditional manual cartoning method has low efficiency, irregularity and high risk of contamination. In order to solve these bottlenecks, the pipette tip automatic corking cartoning machine came into being. This automated equipment can realize the integrated operation of automatic loading, precise corking, cartoning, capping and testing, which greatly improves the production efficiency and product qualification rate, and meets the demand for high-quality consumables in the field of laboratories and pharmaceuticals.

Definition and Composition of Pipette Tip Automatic Corking and Cartoning Machine

1.What is pipette tip automatic cartoning machine?

Pipette tip automatic core filling and cartoning machine is a kind of intelligent equipment integrating automatic feeding, core filling, cartoning, capping and testing. It can automatically arrange the pipette tips into the carton according to the specified quantity and accurately insert the chips or gaskets to ensure the sealing and cleanliness of the products. The whole machine adopts PLC control system and visual inspection technology to realize high-speed and stable automatic operation, reduce manual operation and improve production efficiency and quality consistency.

2.Main components of automatic core stuffing cartoning machine

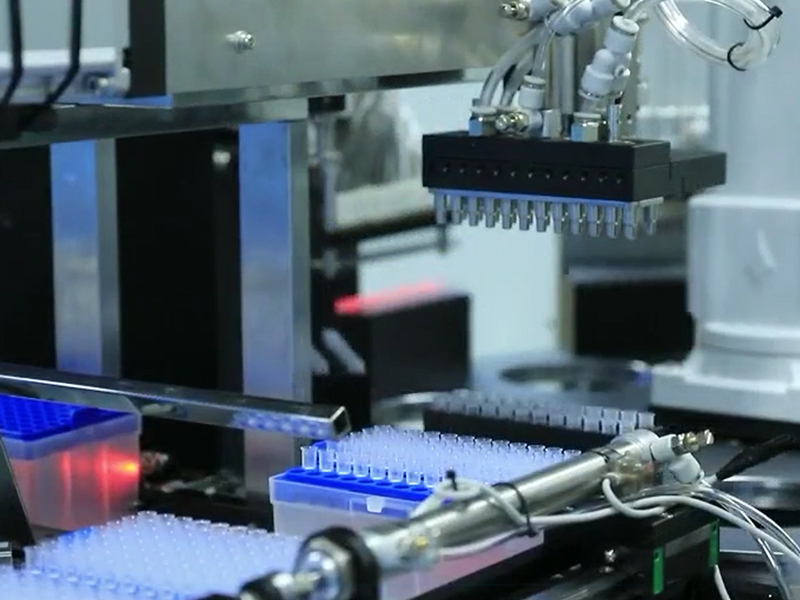

Automatic loading system: the bulk pipette tips are automatically sorted and arranged neatly, and transported to the assembly station through vibration plate or hopper.

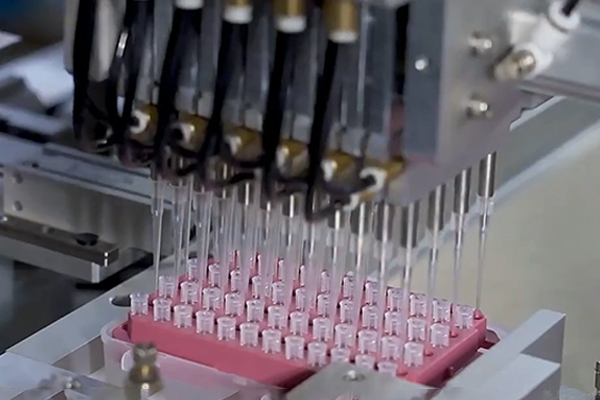

Core stuffing device: Automatically and accurately insert the chips or gaskets into the mouth of the pipette tips to ensure the sealing and air tightness.

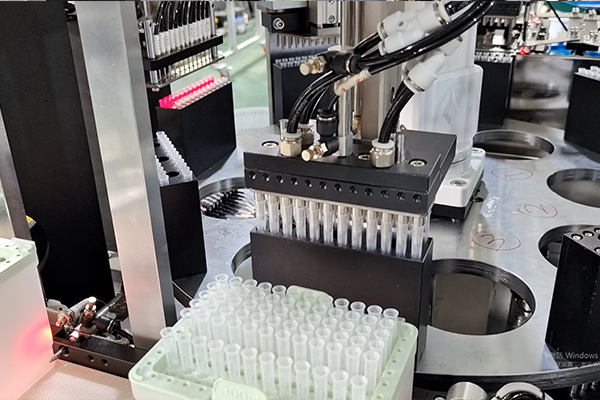

Cartoning system: Automatically carton the pipette tips into plastic boxes or trays according to the set quantity.

Automatic Capping and Locking System: After the cartoning is completed, the lid is automatically capped and fastened to prevent contamination and falling off.

Detection and Rejection System: Visual inspection and laser sensor are adopted to detect defective products and reject non-conforming products.

Control and monitoring system: PLC control and touch screen interface are adopted to realize parameter setting, real-time monitoring and production data tracing.

The workflow of pipette tip automatic core filling and cartoning machine

1. Feeding and sorting: The bulk or arranged pipette tips will be conveyed to the equipment through automatic feeding machine. Vibrating plate or conveyor belt is used to automatically sort the pipette tips and arrange them neatly in the assembly station. Precise positioning ensures that each pipette tip is oriented in the same direction, which is convenient for subsequent corking and cartoning operations.

2. Automatic corking and assembly: The corking device automatically grabs the pre-installed sealing chips or gaskets and accurately inserts them into the pipette tip orifice. It ensures the accurate position and consistent depth of the core plugging to ensure a good sealing effect. High-end equipment can realize synchronous core plugging operation with two or more heads to improve production capacity.

3. Automatic cartoning and capping: Automatically carton the pipette tips into plastic boxes or trays according to the set quantity. The number of cartoning is accurate and consistent, which is in line with the packaging specifications. The automatic capping device covers the lid on the mouth of the box and carries out snap or lock lid operation to prevent loosening.

4. Detection and Rejection: Visual inspection and laser sensor are used to detect whether the suction head is skewed, missed or defective. Unqualified products are automatically rejected to ensure qualified product quality.

5. Output and counting of finished products: After finishing cartoning, the products are automatically output to the finished product conveyor belt. Automatic counting and labeling of production batch and date, convenient for traceability and management.

Advantages of pipette tip automatic cartoning machine

1. High-efficiency production, increase production capacity: automated equipment can realize continuous uninterrupted operation, production efficiency is much higher than manual operation. The daily output can reach tens of thousands to more than 100,000, to meet the needs of large-scale production. Multi-station simultaneous operation further enhances the production efficiency.

2. High precision and product consistency: The automatic core stuffing and cartoning process has precise positioning and minimal error, ensuring product size and assembly consistency. The visual inspection system can effectively eliminate defective and inferior products to ensure the pass rate.

3. Reduce labor cost and error: the equipment adopts automatic feeding and cartoning to reduce manual operation and save labor cost. Avoid the risk of leakage, inconsistent quantity and pollution that may be caused by manual cartoning. Easy to operate, only a small number of personnel to monitor and maintain.

4. Comply with clean and sterility requirements: the whole machine is made of stainless steel and clean material, which meets the standard of clean room for medicine and laboratory. Automatic capping and sealing prevents secondary contamination in the cartoning process. Meet the pharmaceutical GMP and laboratory consumables production standards.

As an important equipment in the field of biomedical and laboratory consumables manufacturing, pipette tip automatic corking cartoning machine realizes the integration of automatic feeding, corking, cartoning and capping during the production process by virtue of its high efficiency automation, precise cartoning and detection and rejection functions, which effectively improves the production efficiency and product quality. With the continuous development of intelligent manufacturing and automation technology, this equipment will become an important tool for laboratory consumables manufacturers to enhance their competitiveness and market share.