Release Date:2025-03-29 16:11:54 Popularity:

In modern industrial production, with the diversification of market demand and the complexity of the production process, standardized automation equipment has been unable to meet the needs of some enterprises on personalized, flexible production. This has led to the rapid development of non-standard automation equipment customization. Non-standard automation equipment refers to the customer's specific needs and production processes, specifically designed, developed and manufactured automation equipment. It is characterized by customized functions, process exclusivity, high efficiency, flexibility, applicable to complex, variable or special production scenarios, widely used in automotive, electronics, medical, food, daily chemical and new energy and other fields.

First, the definition and characteristics of non-standard automation equipment customization

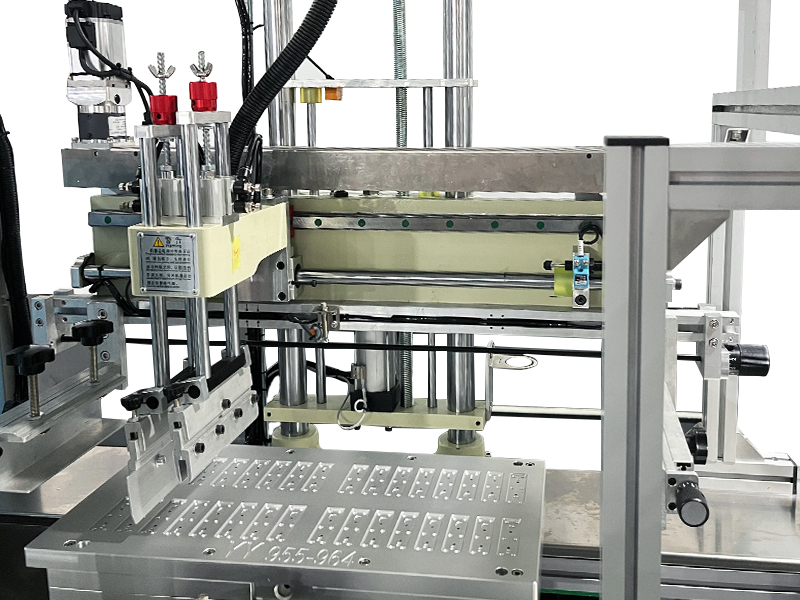

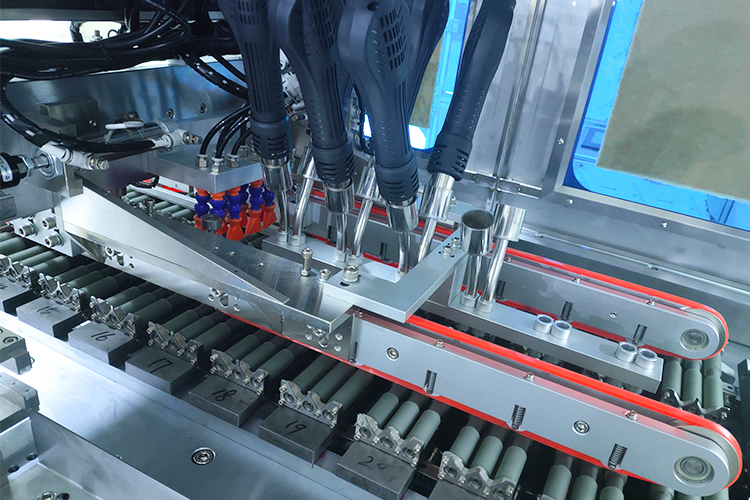

1. Non-standard automation equipment refers to non-standardized, customized automation equipment based on specific processes and production requirements. It is different from general-purpose equipment, usually has the following characteristics:

Strong exclusivity: customized according to the customer's production process and product demand, can not be copied on a large scale.

Personalized design: equipment structure, function, size and parameters are designed according to specific needs.

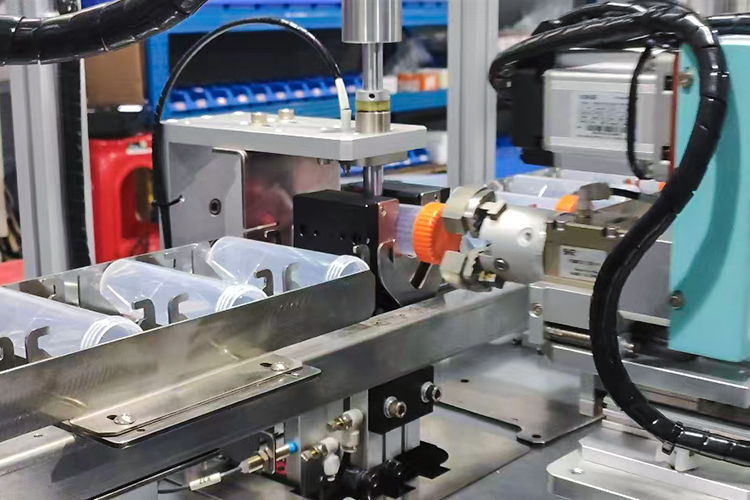

High degree of automation: automatic feeding, assembly, testing, packaging and rejection and other functions can be realized.

Flexible production: the parameters can be quickly adjusted to adapt to the multi-species small batch production mode.

2. Features of non-standard automation equipment

Customized design: tailor-made according to customer needs, to achieve complex process automation.

High production efficiency: the equipment has a high degree of automation, reducing manual operation and improving production efficiency.

Flexibility and compatibility: can be quickly adjusted to adapt to the production of a variety of specifications.

High precision and stability: adopting high-precision sensors and control system to ensure stable operation of the equipment.

Intelligent control: equipped with PLC, touch screen and remote monitoring system to realize intelligent control and data recording.

Second, the advantages of non-standard automation equipment customization

1. Meet individualized production requirements: adapt to complex, special or unique production processes, automated production. According to the product characteristics of the design of exclusive functions and processes. Suitable for multi-species small batch and customized production model.

2. Improve production efficiency and precision: realize automatic feeding, assembly, testing and packaging, reduce manual intervention. High detection accuracy, capable of realizing micron-level or millisecond-level precision control. Improve production efficiency, reduce defective rate and rework rate.

3. Reduce labor costs and production risks: automated equipment instead of manual labor, reducing manual operation and labor intensity. Reduce manual errors, improve product consistency and qualification rate. Reduce the safety risks and operational errors caused by manual operation.

4. Flexibility and expandability: support modular design and expansion, easy to upgrade the capacity later. Can be docked with MES and ERP systems to realize traceability of production data. Flexible to adapt to multi-specification, multi-process and multi-batch production.

Non-standard automation equipment customization as a modern manufacturing flexible and intelligent production of an important means to effectively meet the personalized, complex and high-precision production needs. It not only improves production efficiency, but also reduces labor costs and error rate. In the era of intelligent manufacturing and industry 4.0, non-standard automation equipment customization will continue to help enterprises achieve efficient production, accurate detection and quality assurance.