Release Date:2025-01-10 16:03:40 Popularity:

With the continuous improvement of the level of automation of industrial production, automated dispenser equipment plays an increasingly important role in the manufacturing industry. As an efficient and accurate dispensing tool, automated dispenser equipment not only improves production efficiency, but also has significant advantages in ensuring product quality and reducing costs. In this paper, we will discuss in detail the characteristics and market prospects of automated dispenser equipment from the principle of the equipment, application areas and advantages.

The working principle of automated dispenser equipment

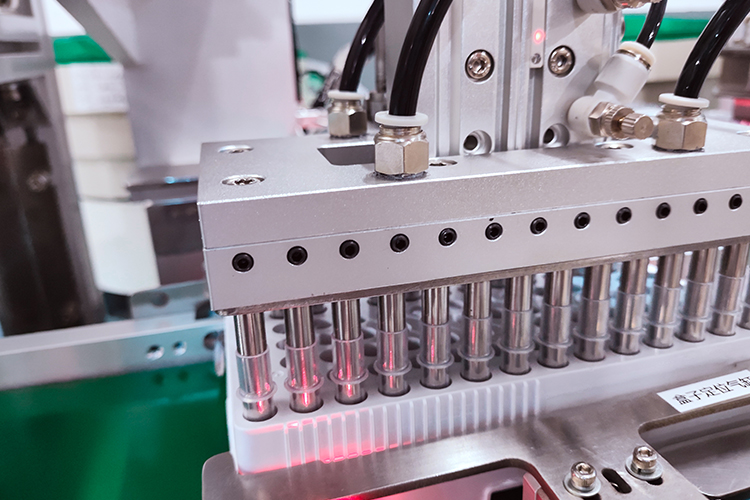

Automated dispenser equipment through the robotic arm or other automated devices, the liquid material (such as glue, lubricants, sealants, etc.) will be accurately coated in the specified location. Its core components include a dispensing needle, a dispensing control system, a drive system, and a material supply system. During operation, the control system controls the needle's trajectory and dispensing volume according to a preset program, thus realizing high-precision dispensing tasks.

In addition, modern automated dispenser equipment is often equipped with a visual recognition system that allows real-time monitoring of the dispensing process via camera, further improving accuracy and reliability. Through deep integration with the production line, the dispenser equipment is able to meet the dispensing needs of different products, such as ring dispensing, linear dispensing and multi-point positioning dispensing.

Application areas of automated dispenser equipment

Electronic manufacturing industry: in the electronic manufacturing industry, automated dispenser equipment is mainly used for circuit board components fixed and sealed, such as chip packaging, circuit board protection, electronic components bonding. High-precision dispensing technology can effectively avoid glue spillage and uneven phenomenon, and improve the product qualification rate.

Automotive industry: In automotive production, automated dispenser equipment is widely used for coating sealant, anti-vibration adhesive and lamp bonding and other processes. Its high efficiency and stability can meet the production needs of large-scale auto parts.

Medical devices: The medical industry requires high precision and cleanliness of products. Automated dispenser equipment plays an important role in the production of disposable medical devices, laboratory supplies and medical electronics.

Consumer electronics: smart phones, tablets, smart wearable devices and other consumer electronics products require precision dispensing processes. Dispenser equipment ensures precise distribution of glue, which enhances the appearance and performance of the product.

Advantages of automated dispenser equipment

High precision and stability: automated dispenser equipment can ensure the uniformity of the dispensing amount and the accuracy of the position through the precision control system, which effectively reduces the errors caused by manual operation.

Improve production efficiency: compared with the traditional manual dispensing, automated dispenser equipment can run continuously and stably, significantly reducing the production cycle, suitable for mass production.

Cost saving: Dispenser equipment can accurately control the amount of glue used to avoid waste. At the same time, its high degree of automation, can reduce manual intervention, reduce labor costs.

Adapt to diversified needs: dispenser equipment can flexibly adjust the dispensing program according to the different shapes of products and process requirements, which is widely applicable to a variety of complex processes.

Reduce scrap rate: the accuracy and consistency of dispensing can significantly improve the quality of products and reduce the rate of defective products and rework.

With the rapid development of intelligent manufacturing, the market demand for automated dispenser equipment is increasing. In the future, the degree of intelligence of the equipment will be further improved, such as the introduction of artificial intelligence algorithms for autonomous adjustment, as well as the realization of seamless connection with the industrial Internet of Things. In addition, in order to adapt to environmental requirements, dispensing machine equipment will also pay more attention to energy saving and material utilization.

Automated dispenser equipment, as an important tool in modern manufacturing, has been widely used in various industries. Its high efficiency, precision and flexibility, not only to meet the complex production needs, but also for the enterprise to bring significant economic benefits. With the continuous progress of technology, dispensing machine equipment will usher in a broader space for development, help industrial production to intelligent, green direction.