Release Date:2025-01-10 15:29:16 Popularity:

With the rapid development of medical and scientific research, the demand for reagents is increasing, and the requirements for production efficiency and product quality are also becoming increasingly stringent. In this regard, the fully automated reagent production line has established itself as a powerful assistant in medical and scientific research to improve efficiency and ensure quality. In this article, we will comprehensively analyze the significance of this advanced equipment from four aspects: the working principle of fully automatic reagent production line, technical advantages, applications and future development trends.

Firstly, the working principle of automatic reagent production line

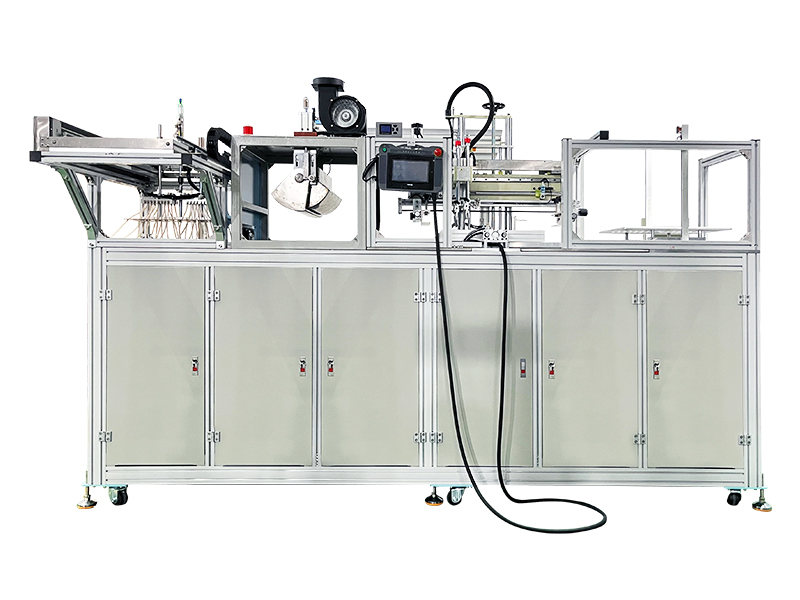

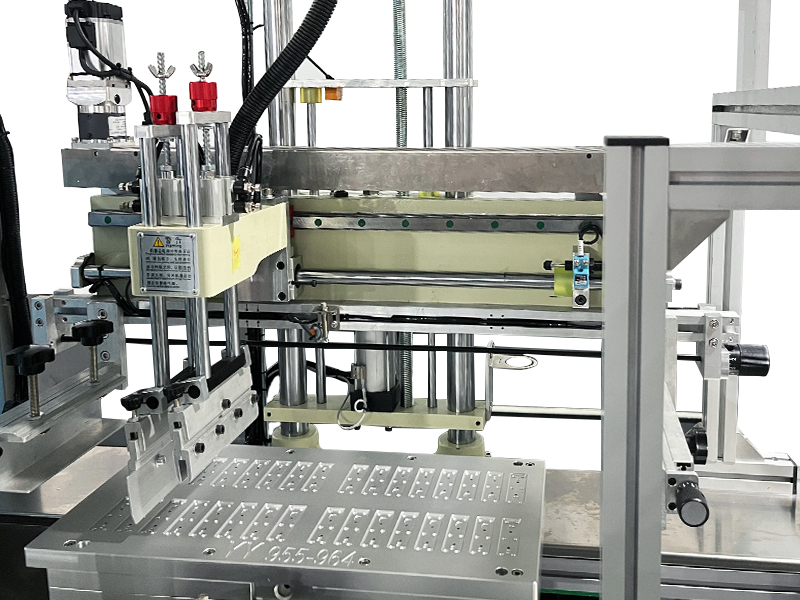

Automatic reagent production line is a set of reagent filling, encapsulation, labeling, packaging in one automatic production equipment. Its basic principle is to achieve the coordinated operation of each link through advanced PLC control system. The production line is equipped with filling module, capping module, labeling module and packaging module, which interact with each other through sensor monitoring and feedback to ensure a smooth production process. For example, in the filling area, the liquid reagent is injected into the container according to the preset amount using a precise dosing system, then the cap and label are automatically applied, and finally the outer packaging is created.

Secondly, the technical advantages of fully automated reagent production line are as follows

1. high efficiency: the production speed of fully automated reagent production line is much faster than traditional manual operation, and it can perform thousands or even tens of thousands of filling and encapsulation tasks per hour. The high efficiency can meet the demand of medical institutions and research units for large quantities of reagents.

2) Accuracy: the equipment is equipped with high-precision measuring device, which can ensure that the filling volume of each reagent vial is completely in accordance with the set standard, thus avoiding reagent loss or waste due to inaccurate dosing.

3) Stability: the production line is stable and can run for a long time without interruption, which greatly reduces the errors caused by fatigue in manual operation. In addition, the failure rate of automated equipment is low, and the maintenance cost is relatively low.

4) Intelligence: advanced monitoring and alarm systems can detect anomalies in the production process in real time. For example, if it is detected that the bottles are not placed correctly or the filling volume does not meet the preset value, the system will automatically alarm and stop the operation to prevent poor quality products from flowing out.

5. cleanliness and hygiene: reagents are delicate chemical products and the production process requires a high level of environmental hygiene. The fully automatic reagent production line is hermetically sealed to eliminate the possibility of contamination and complies with the GMP (Good Manufacturing Practice) standard.

Applications of the automatic reagent production line

A fully automated reagent production line is often used in medical, research and biopharmaceutical applications. In particular, the following aspects are concerned:

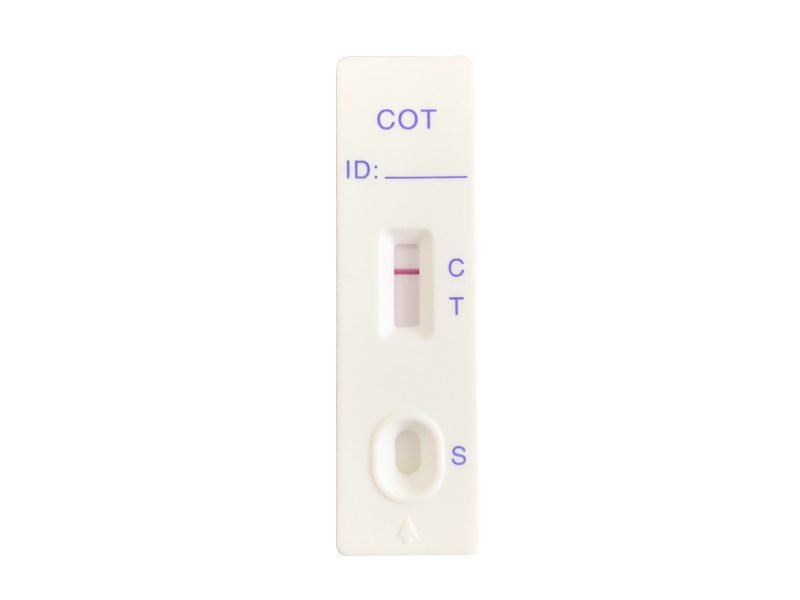

Medical research: a fully automated reagent production line can be used to produce serum reagents, nucleic acid isolation reagents, chemiluminescence reagents, etc.

Laboratory research: reagents for scientific research, such as buffers, filling and packaging of test solutions.

Vaccine production: in vaccine development and production, fully automated reagent production lines can also play an important role, especially in emergency production, equipment efficiency is particularly important.

Fourth, the future development trend of automatic reagent production line

With the continuous progress of technology, the performance and functions of the automatic reagent production line are also being modernized:

1) Intelligent Upgrade: The introduction of artificial intelligence and big data technologies will further increase the intelligence level of the equipment and allow the entire process to be automatically monitored and optimized.

2) Modular design: The future production line will be more flexible and adaptable to the requirements of producing different types of reagents due to its modular design.

3) Improved environmental protection: The automatic reagent production line will use more environmentally friendly materials and processes in line with the green manufacturing concept to reduce energy consumption and waste emissions.

4) Global application: With the internationalization of medical and scientific research, the reagent production line will be extended to more and more countries and regions, contributing to global health care.

Fully automatic reagent production line has become an indispensable equipment for modern medical and scientific research industry, with features such as high efficiency, precision, intelligence and environmental protection. It not only greatly improves the efficiency of reagent production, but also provides reliable assurance of product quality. It can be assumed that in the future wave of medical and technological innovation, the fully automatic reagent production line will continue to play an important role in pushing the development of the industry to a higher level.