Release Date:2025-07-29 11:45:14 Popularity:

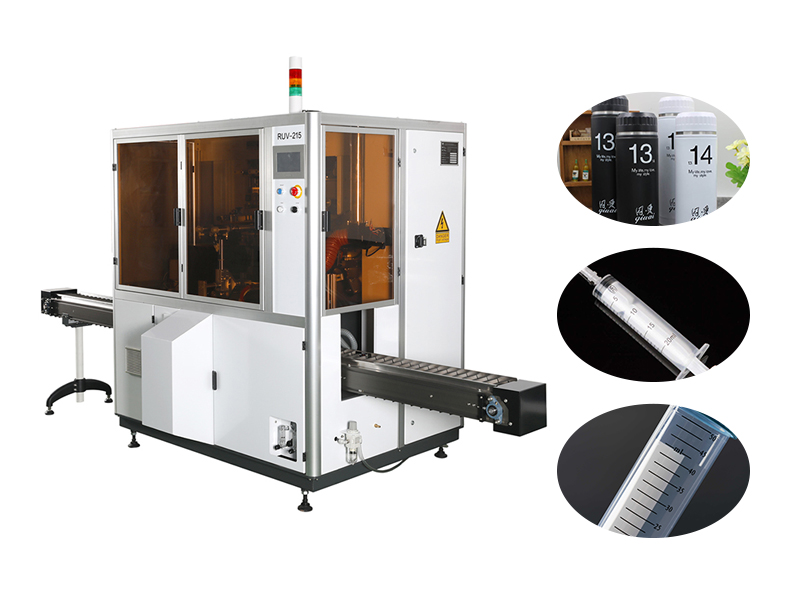

As the name implies, the automatic screen printer is a device that automatically completes the entire process of screen printing through mechanical and electronic control systems. It can be applied to product surfaces of various materials and shapes, such as plastic, glass, metal, ceramic, paper, etc., and can efficiently complete screen printing of patterns, text, barcodes and other contents. Compared with traditional manual screen printing, it has a higher degree of automation, can achieve continuous batch production, effectively avoid human errors, and improve consistency.

1. The core advantages of the automatic screen printer

High printing accuracy and clear patterns: The automatic screen printer adopts precision servo drive and high-precision positioning system, which can control the printing position error within the micron range, and can ensure printing clarity and alignment accuracy even on complex or curved workpieces.

Production efficiency is significantly improved: Through the integrated process of continuous loading, automatic alignment, screen printing, drying, unloading, etc., the automatic screen printer can greatly increase the printing speed, meet the growing demand for batch orders, and is suitable for 24-hour uninterrupted production.

Easy operation, saving manpower: The equipment is equipped with a human-machine interface (HMI) and an automatic adjustment system, making the operation intuitive and simple, reducing the reliance on highly skilled operators and significantly reducing labor costs.

Wide application range and strong adaptability: The automatic screen printer is not only suitable for flat printing, but also can realize automatic printing of round, curved and special-shaped workpieces through customized modules, meeting various customized and complex printing needs.

Good printing stability and convenient maintenance: The equipment has a reasonable design structure, long service life, simple daily maintenance and low failure rate, providing strong guarantee for the company's continuous production.

2. Wide application in various industries

Automatic screen printers have important applications in many industries, especially in the following fields:

Electronic industry: such as circuit boards, membrane switches, touch panels and other surface patterns or conductive ink printing;

Medical industry: scale and logo printing of test tubes, centrifuge tubes, culture bottles, pipettes and other experimental consumables;

Daily chemical industry: LOGO and label pattern printing on bottle packaging;

Automotive industry: graphic screen printing of dashboards, buttons and other components;

Packaging industry: decoration and brand printing of outer packaging such as plastic boxes, blister packaging, glass bottles, etc.

As a product of the integration of screen printing technology and automation equipment, automatic screen printers are helping traditional printing processes to transform and upgrade towards intelligence, efficiency and precision. Whether in improving production efficiency, ensuring printing quality, or in the strategy of reducing costs and increasing efficiency of enterprises, automatic screen printers play an irreplaceable and important role.