Release Date:2025-07-25 11:15:58 Popularity:

Automation equipment customization manufacturers refer to manufacturers that specialize in providing non-standard customized automation equipment and complete line solutions for enterprises. This type of manufacturer is not only an equipment supplier in the traditional sense, but also an intelligent manufacturing technology service provider that integrates solution design, structure development, electrical control, software and hardware integration, installation and commissioning, and after-sales maintenance. They develop highly adaptable personalized equipment and systems based on customers' production needs, product characteristics, and process flows.

1. The core advantages of customization

Highly compatible with the production process: Compared with standard equipment, customized equipment can accurately connect to customer process links to achieve station optimization and maximize production capacity.

Improve the level of automation: Customized manufacturers carry out system integration based on customer pain points, and often achieve collaborative automation of multiple links such as feeding, testing, assembly, and packaging, reducing manual intervention.

Save cost space: Through tailor-made structure and program control, not only efficiency is improved, but also energy consumption and raw material waste can be reduced.

Support later expansion and upgrade: Many customized equipment have modular structures, which are convenient for customers to quickly adapt when expanding production capacity or switching products in the future.

More professional technical services: Customized manufacturers are familiar with the structure and procedures of the entire set of equipment, and can provide fast-response maintenance and optimization services to ensure the continuity of customer production.

2. Wide and diverse industries served

The service areas of customized automation equipment manufacturers cover a wide range, almost penetrating into major manufacturing industries, including but not limited to:

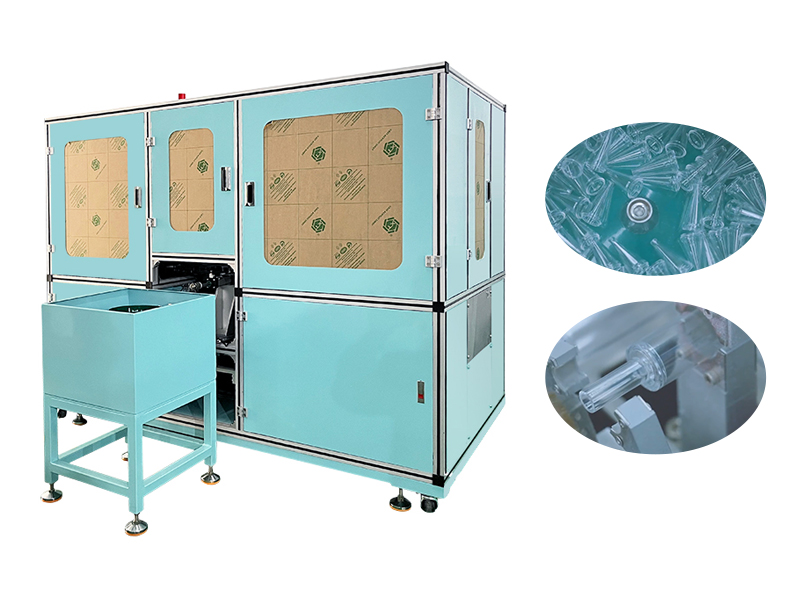

Medical consumables industry: such as automatic assembly, welding, silk screen, and filling production lines of test tubes, pipettes, and centrifuge tubes;

Daily chemical industry: automatic equipment customization such as facial mask filling, toothpaste sealing, and perfume filling;

Hardware and plastics: automatic hook insertion, assembly, and packaging systems for small hardware;

Packaging industry: quantitative packaging, blister packaging, weighing and labeling, and boxing systems;

Electronic industry: automatic dispensing, mounting, testing, and sorting of parts and components.

3. Technical capabilities of customized automation equipment manufacturers

Excellent customized automation equipment manufacturers usually have the following technical capabilities:

Precise structural design: The engineering team customizes the mechanical module according to the product structure to ensure stable equipment operation.

Electrical system integration: Independently develop PLC programs and human-machine interfaces to achieve multi-station linkage control and real-time data monitoring.

Visual recognition technology: Integrated CCD visual system to achieve product positioning, defect detection and precise assembly.

MES system docking capability: Some manufacturers can connect equipment to the company's MES system to help customers achieve production digitization and traceability management.

4. important considerations for selecting customized manufacturers

For enterprises, it is very important to choose a suitable automation equipment customization manufacturer, which should be comprehensively evaluated from the following aspects:

Whether the R&D and design capabilities are strong; whether they have experience in whole-line delivery and commissioning; whether they can provide long-term after-sales and technical support; whether they have served customers in the same industry and have mature cases; whether the quotation is reasonable and whether the delivery period is controllable.

A reliable manufacturer is not only an equipment provider, but also a partner for optimizing customer production processes.

Today, with the increasing rise of intelligent manufacturing, automation equipment customization manufacturers are becoming an important force in promoting industrial transformation and upgrading. With the continuous improvement of the market demand for high-efficiency, high-precision and personalized production, general-purpose equipment can no longer meet the complex process requirements of all enterprises. At this time, automation equipment customization manufacturers with R&D capabilities, design capabilities and whole-line integration capabilities came into being, providing tailor-made solutions for different industries and helping companies move into a new era of intelligent manufacturing.