Release Date:2025-07-29 11:16:34 Popularity:

An automatic filling machine is a device that automatically injects liquids, pastes, powders, particles and other materials into a container according to a set amount. According to the different material properties and filling methods, it can be subdivided into liquid automatic filling machines, paste filling machines, powder filling machines, particle filling machines and other types. Among them, liquid automatic filling machines are the most common and are widely used in the packaging process of beverages, water, alcohol, edible oil, medical liquids, detergents and other products.

1. The core advantages of automatic filling machines

Filling is accurate and waste is reduced: automatic filling machines use high-precision sensors, flow meters or weighing systems to achieve milliliter-level or even finer metering control, which not only meets product quality control requirements, but also greatly reduces material waste.

Efficient production and manpower saving: The equipment can achieve continuous and multi-head simultaneous filling, greatly improve production capacity, and adapt to batch and large-scale production needs. At the same time, automatic filling replaces traditional manual operations, effectively alleviating problems such as difficulty in hiring and high labor costs.

Strong adaptability and convenient operation: Modern automatic filling machines adopt modular design and human-machine interface. Users can quickly switch molds or adjust parameters according to containers of different specifications, and flexibly adapt to the production needs of multiple categories of products.

High degree of automation and strong stability: Automatic filling machines can be linked with capping machines, labeling machines, testing equipment, cartoning machines, etc. to form a fully automatic packaging production line, reduce human intervention, and improve the stability of the entire line operation.

Sanitary and safe, in line with standards: Especially in the food and pharmaceutical industries, the equipment is made of stainless steel to meet the requirements of relevant specifications such as GMP and QS. Some high-end models are also equipped with CIP/SIP automatic cleaning systems to ensure hygiene and safety.

2. Typical application areas

Food and beverage industry: such as filling of mineral water, juice, dairy products, sauces, cooking oil, honey and other products;

Medical and health care industry: used for aseptic filling of oral liquid, disinfectant, syrup, lotion and other liquid medicines;

Daily chemical industry: packaging of liquid or paste such as shampoo, shower gel, detergent, cosmetics;

Chemical industry: quantitative filling of liquid chemical products such as lubricating oil, coating, pesticide, chemical solution.

3. Brief description of the classification of automatic filling machines

Classification by filling materials:

Liquid filling machine: suitable for liquids with good fluidity;

Paste filling machine: suitable for high viscosity materials;

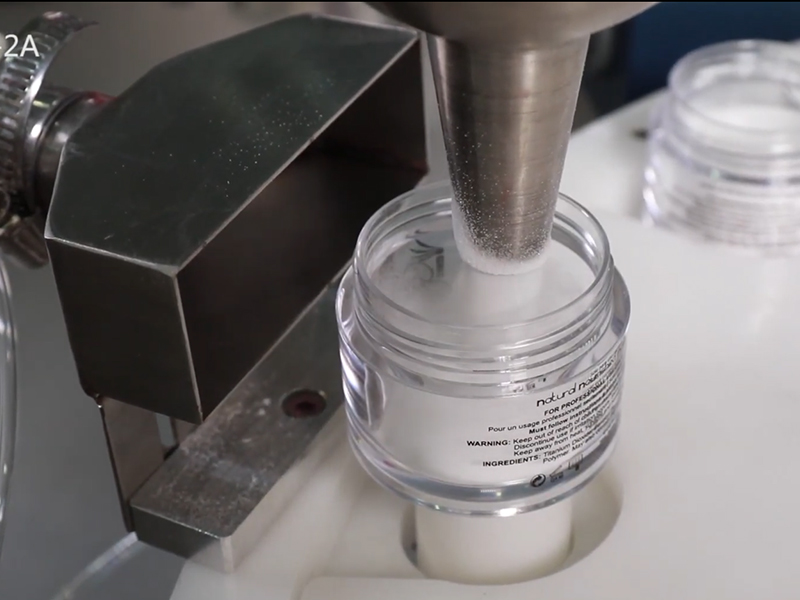

Powder filling machine: mainly for dry powder products;

Particle filling machine: used for granular or small granular materials.

Classification by filling method:

Normal pressure filling machine: relies on gravity flow, suitable for liquids with good fluidity;

Isobaric filling machine: suitable for gaseous liquids such as carbonated beverages;

Vacuum filling machine: suitable for viscous liquids, helps to reduce bubbles;

Piston filling machine: suitable for filling thick or granular materials.

As a key link in the intelligent packaging system, the automatic filling machine has not only greatly promoted the improvement of production efficiency in various industries, but also played an increasingly important role in improving product quality, reducing costs and ensuring safety. For companies that pursue efficient, stable and high-quality output, choosing a suitable automatic filling machine has become an important step in their intelligent manufacturing upgrade.