Release Date:2025-07-23 11:24:26 Popularity:

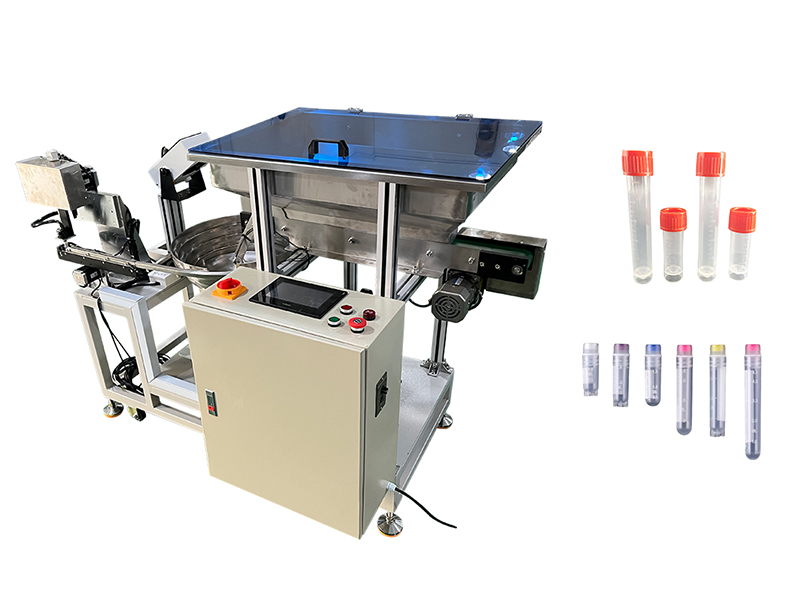

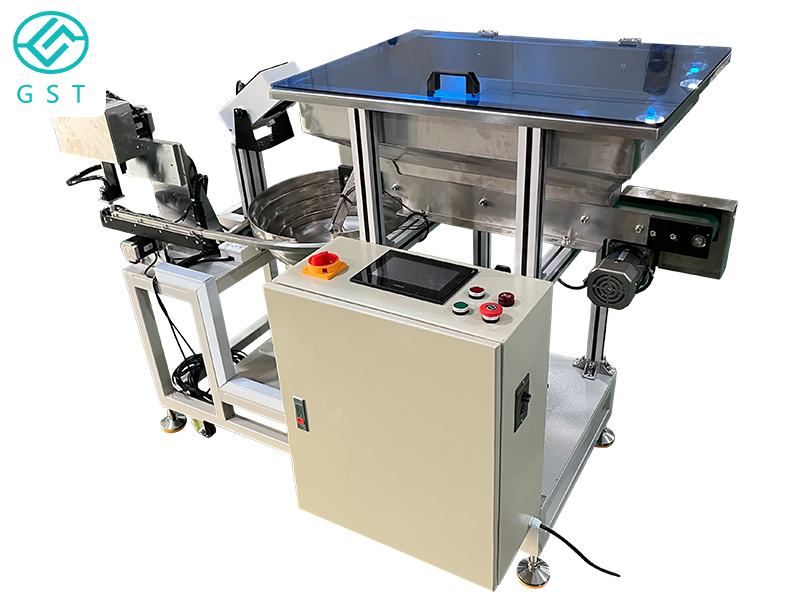

The automatic feeding machine for cryopreservation tubes is an automated equipment specially designed for automatic material sorting and conveying of cryopreservation tubes. Its main function is to efficiently and orderly convey cryopreservation tubes in disordered stacking or bulk state to downstream stations such as automatic screen printing machines, automatic capping machines, and automatic testing equipment. This equipment not only liberates manual operation and improves efficiency, but also effectively reduces the risk of contamination caused by human contact. It is particularly suitable for places with high requirements for GMP and clean production.

1. Equipment composition and working principle

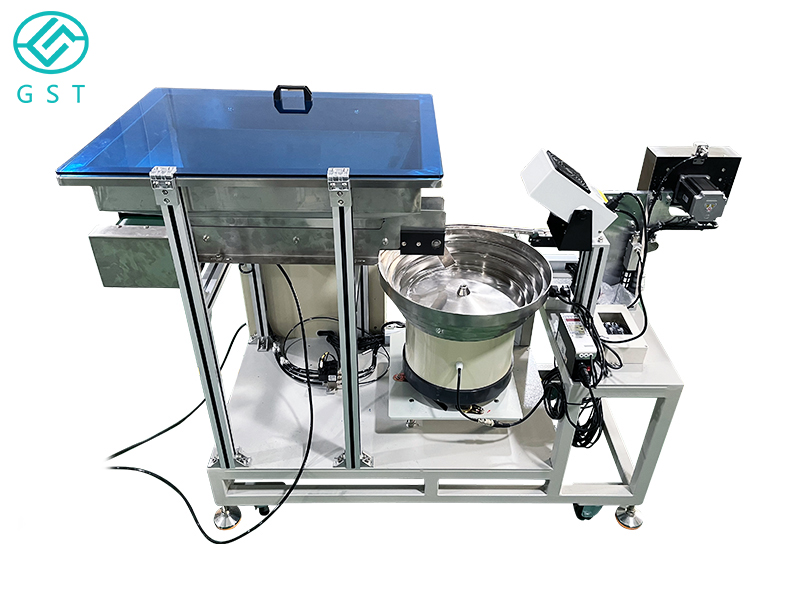

The automatic feeding machine for cryopreservation tubes is usually composed of the following core modules:

Feeding system: A large number of cryopreservation tubes are introduced into the material sorting area by means of vibration plate, elevator or belt conveyor to achieve stable feeding.

Management mechanism: Through the structure of track guidance, mechanical separation or roller screening, the cryopreservation tubes are arranged in the same direction to ensure the smooth progress of subsequent processes.

Detection device: Equipped with photoelectric sensors or visual recognition systems to identify abnormal conditions such as blocked tubes, crooked tubes, foreign objects, etc., and automatically remove or alarm to ensure production stability.

Conveying device: Use belts, push rods, mechanical arms and other structures to accurately convey neatly arranged cryopreservation tubes to designated workstations, and seamlessly connect with automatic capping, automatic coding and other equipment.

2. Advantages of automatic cryopreservation tube feeder

Improve production efficiency: Realize uninterrupted automatic feeding, run synchronously with the production line rhythm, and effectively improve the overall operation efficiency of the production line.

Reduce labor costs: Replace manual management and feeding, reduce dependence on skilled workers, and reduce manpower investment and management difficulty.

Ensure product cleanliness: Fully enclosed structure and automated operation reduce manual contact and meet the production requirements of high-cleanliness experimental consumables.

Strong compatibility: Customized tracks and molds can be used for various specifications of cryopreservation tubes such as 5ml, 10ml, 15ml, 50ml, etc., with flexible switching.

High stability and low failure rate: Adopt high-quality electrical components and control systems, stable operation, and support all-weather continuous operation.

The automatic cryopreservation tube feeder is not only a material handling equipment, but also an important support for promoting the automation, efficiency and cleanliness of cryopreservation tube production lines. With the increasing market demand for laboratory consumables and the continuous improvement of quality requirements, if companies want to remain invincible in the fierce competition, they must rely on such advanced and efficient automation equipment.