Release Date:2025-07-23 11:01:32 Popularity:

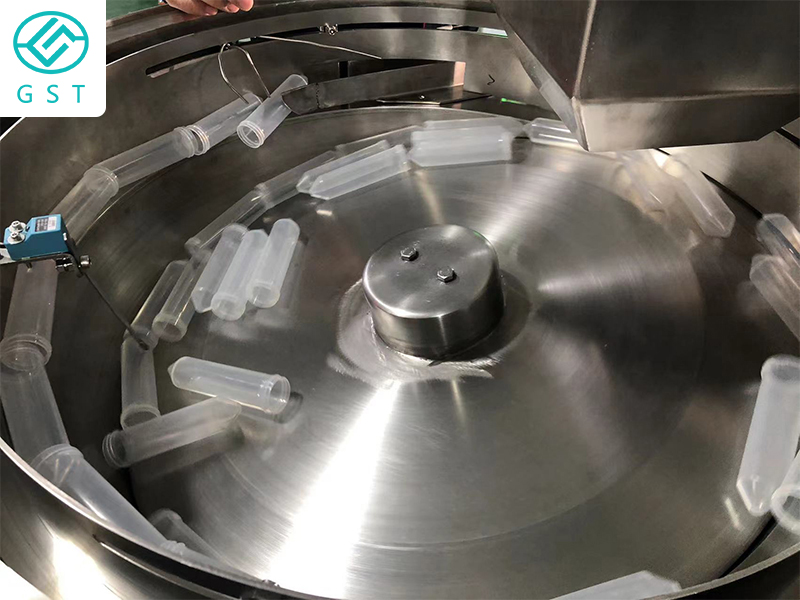

The centrifuge tube automatic feeder is an automated device used to automatically straighten and transport centrifuge tubes in bulk or stacked state to subsequent processing or assembly stations (such as automatic plugging, capping, silk screen printing, etc.). The equipment can operate independently or be integrated with the entire automated production line. It mainly undertakes the basic tasks of "sorting, conveying, and directional arrangement", which is a prerequisite for ensuring subsequent efficient and accurate operations.

1. Working principle and structural composition of the equipment

The centrifuge tube automatic feeder is usually composed of the following main modules:

Feeding system: Generally, a vibration plate, elevator or belt conveyor structure is used to automatically lift the centrifuge tube from the storage box to the work surface.

Management device: The messy and disordered centrifuge tubes are straightened one by one through the track and guide mechanism to ensure the same direction (such as the cover facing up or down), providing stable feeding for subsequent processes.

Detection module: Some equipment integrates photoelectric or visual detection systems, which can identify abnormal tubes (such as blockage, wrong direction, damage) and remove them in time to improve the stability of the production line.

Conveying mechanism: Use slide rails, conveyor belts or servo motor push rods to send neatly arranged centrifuge tubes to the next process (such as automatic plugging, capping, etc.) at a set rhythm.

2. Core advantages and technical highlights

Improve production efficiency: It can realize continuous, stable and unmanned feeding, reduce equipment idling time, seamlessly connect with the whole line rhythm, and greatly improve the overall efficiency of the production line.

Reducing labor costs: Replace traditional manual material sorting and feeding operations, reduce labor intensity, reduce the number of employees, and achieve uninterrupted feeding around the clock.

Ensure direction consistency: Ensure the direction of the centrifuge tubes through precise sorting mechanisms to avoid errors or shutdowns in subsequent processes due to wrong directions.

Reducing pollution risks: Adopting closed structure and clean materials to reduce human contact, it meets GMP and other clean production requirements, and is particularly suitable for medical and biopharmaceutical industries.

Compatible with multiple specifications: The mold can be quickly replaced according to the model of the centrifuge tube (such as 5ml, 10ml, 15ml, 50ml, etc.), with good flexible production capabilities.

The centrifuge tube automatic feeder is not only a feeding device, but also the starting point for the efficient operation of the entire automated production line. Its precision and efficiency determine the rhythm and stability of the entire assembly line. As the application scale of centrifuge tubes continues to expand in various medical and experimental scenarios, this equipment will continue to play a key role and help consumables manufacturing companies move towards intelligence, automation, and high quality.