Release Date:2025-03-27 16:06:43 Popularity:

In modern industrial production, product packaging is an important and indispensable link, which directly affects the appearance of product quality, market competitiveness and transportation safety. The traditional manual cartoning method has the problems of low efficiency, poor packaging accuracy, high labor cost, and it is difficult to meet the packaging needs of large volume and standardization. As an efficient and intelligent packaging equipment, automatic cartoning machine can realize automatic opening, filling, folding, sealing and other processes, which greatly improves the production efficiency and packaging quality. It is widely used in food, medicine, cosmetics, daily chemicals, hardware and electronics industries, helping enterprises to achieve intelligent production.

I. Working principle and structure of automatic cartoning machine

1. Automatic cartoning machine adopts automatic control and mechanical transmission to load products into cartons according to the set procedure, and complete the folding and sealing. Its workflow usually includes the following steps:

Automatic supply and molding of carton: the carton is sucked up and unfolded for molding through automatic feeding mechanism.

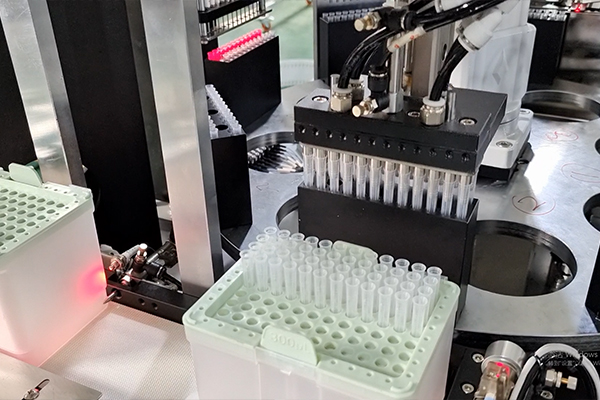

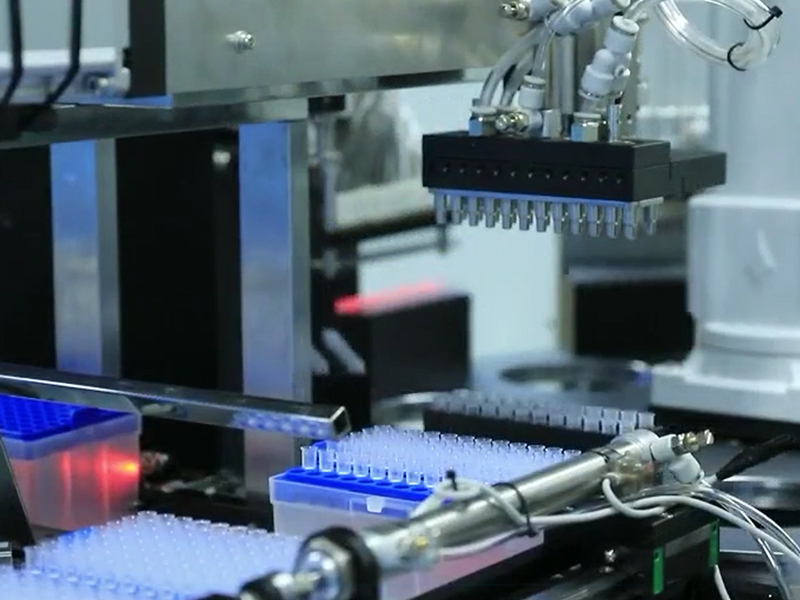

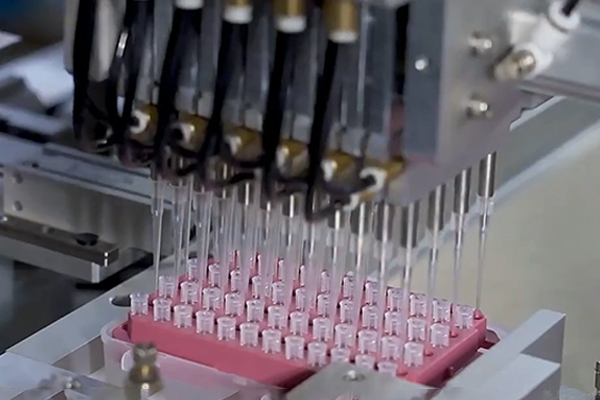

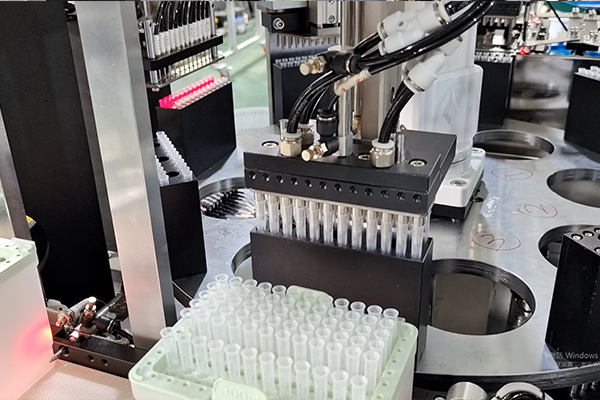

Automatic product loading and cartoning: The products are accurately transported into the carton by conveyor belt or robot.

Lid folding and sealing: Automatic folding of carton lid and sealing of carton by tongue insertion or glue application.

Detection & Rejection: Equipped with detection system to recognize whether it contains products, manuals, etc. and reject unqualified boxes.

2. The automatic cartoning machine is mainly composed of the following structures:

Automatic feeding device: it can automatically convey the products to be cartoned, such as medicine bottles, toothpaste, food bags, etc.

Carton supplying mechanism: automatically picking up the carton and unfolding the molding to ensure the carton is filled accurately.

Folding and sealing device: Folding and sealing can be realized by mechanical structure or pneumatic device.

Control system and detection device: equipped with PLC control and touch screen interface to realize intelligent operation. With detection and alarm function for lack of material, lack of box, failure of box opening.

Classification of automatic cartoning machine

1. Classification according to packing method

Horizontal cartoning machine: products and cartons are transported parallel to each other, and the products are pushed into the carton horizontally by pusher or manipulator. It is suitable for regular or strip-shaped products, such as pharmaceutical packaging, toothpaste boxes, etc.

Vertical cartoning machine: the products fall into the carton vertically from above, suitable for granule, powder or bulk products. Commonly used in food and small hardware packaging.

2.Classification according to the degree of automation

Semi-automatic cartoning machine: the products are put into the carton with manual assistance, and the equipment automatically finishes folding and sealing the carton. Suitable for small batch production or multi-specification product packaging.

Full-automatic cartoning machine: fully automated operation, from opening, filling to sealing the box is completed in one piece. Suitable for large quantity and high efficiency production line.

3.Classification according to sealing method

Tongue insertion cartoning machine: Seal the carton by the tongue insertion mechanism which comes with the carton, with beautiful sealing. Commonly used in medicine and food industry.

Hot melt cartoning machine: use hot melt adhesive to glue the lid of the carton, which is strong and suitable for high speed production. Used in cosmetics, daily chemicals and electronic products packaging.

Advantages of automatic cartoning machine

1. Improve production efficiency and reduce labor cost: automatic cartoning machine can realize continuous high-speed cartoning, production efficiency is 35 times higher than manual cartoning. Automatic operation reduces manual intervention and lowers labor cost.

2. High packaging precision and stable quality: Equipped with precise positioning device and detection system to ensure that each box is filled accurately. The sealing quality is consistent, avoiding the problem of insecure or skewed sealing caused by manual operation.

3. Convenient operation and intelligent control: adopting PLC control system and touch screen operation interface, easy and intuitive to operate. With automatic alarm and fault diagnosis function, easy to maintain. It can be linked with filling machine, labeling machine, coding machine and other equipment to realize intelligent production line.

4. Material saving and environmental protection: the automatic cartoning machine adopts precise carton supply and sealing technology, effectively reducing carton waste. Strong sealing, can prevent product pollution, in line with environmental protection and health standards.

5. Strong compatibility and wide range of application: It can be adapted to different specifications and sizes of cartons and products. Suitable for various shapes of product cartoning, such as bottles, tubes, bags, strips and so on. Convenient mold replacement, suitable for multi-species production needs.

As an important equipment of modern packaging automation, automatic cartoning machine has become the necessary packaging equipment for major production enterprises by virtue of its high efficiency, precision, stability and environmental protection advantages. It not only significantly improves production efficiency and packaging quality, but also reduces labor costs, intelligent, standardized and large-scale production. In the future, with the development of industry 4.0 and intelligent manufacturing, automatic cartoning machine will play an important role in more areas, helping enterprises to move towards a new height of efficient and intelligent production.