Release Date:2025-03-19 15:19:16 Popularity:

In the modern printing industry, screen printing, as an important printing technology, is widely used in the pattern printing of plastics, metals, glass, ceramics, electronic components, textiles and other materials by virtue of thick ink layers, bright colors, strong adhesion, good light resistance and other characteristics. However, the traditional manual or semi-automatic screen printing machine has been unable to meet the current industrial production of high efficiency and high precision needs. Automatic screen printing machine came into being, by virtue of its automation, high-speed operation, precision printing and other advantages, has gradually become the mainstream equipment in the printing industry.

First, the working principle and structure of automatic screen printing machine

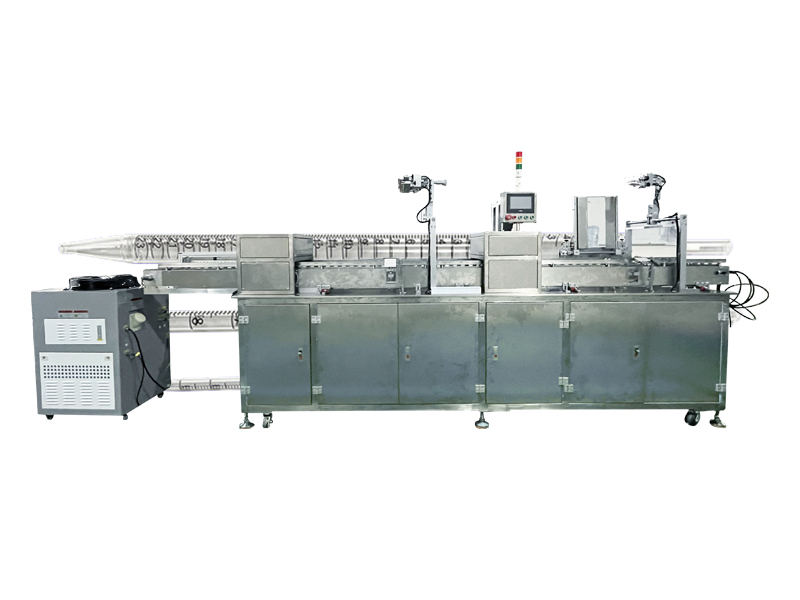

Automatic screen printing machine through the automatic feeding, precise positioning, automatic printing and automatic receipt of materials and other processes, to achieve fast and efficient screen printing. Its main workflow includes:

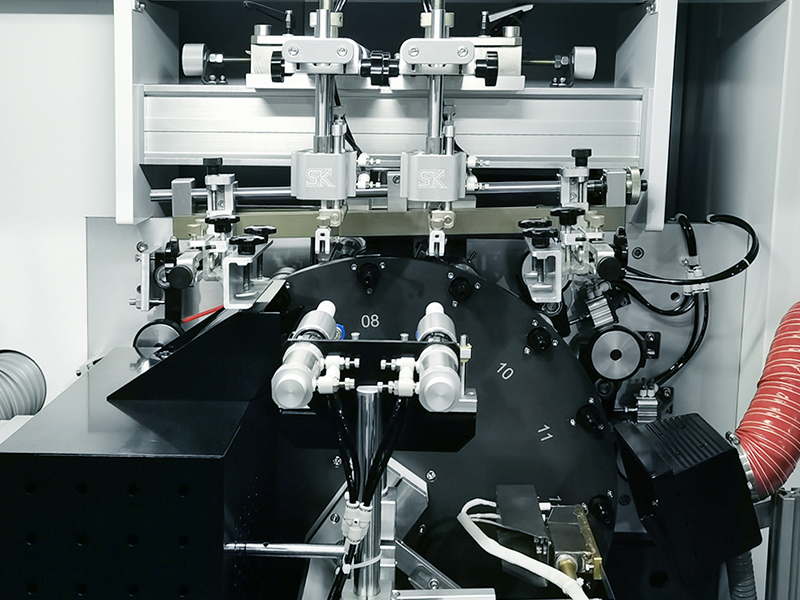

1. Automatic feeding and positioning: the equipment automatically feeds the material to be printed into the printing platform through manipulator or conveyor belt. Equipped with visual positioning system or sensor to ensure accurate printing position and avoid offset.

2. Screen Printing: The ink is evenly coated on the screen by squeegee and transferred to the surface of printed materials through the mesh under pressure. The system can automatically control the squeegee angle, pressure and speed to ensure uniform and stable printing quality.

3. Automatic drying and color fixing: After printing, the product automatically enters the drying area, using UV curing or hot air drying technology to dry the ink quickly and improve adhesion and abrasion resistance.

4. Automatic receiving and stacking: the printed products are automatically output through the conveyor belt and automatically stacked or received, reducing manual intervention.

Second, the core advantages of automatic screen printing machine

1. Improve production efficiency, reduce labor costs: automatic screen printing machine automatic operation, can realize high-speed continuous printing, single machine daily output far more than manual or semi-automatic equipment. Reduce manual intervention, save a lot of labor costs, while improving production stability and consistency.

2. High-precision printing, stable quality: equipped with servo motors and visual positioning system to achieve precise positioning, error control within ± 0.1mm. Uniform thickness of ink layer and clear pattern are suitable for batch printing of fine patterns and complex designs.

3. Easy operation, intelligent control: PLC control system and touch screen interface, intuitive and easy to operate. Support data storage and call function, easy to quickly switch printing parameters, improve production flexibility.

4. Reduce ink waste and save material cost: automatic screen printing machine has ink recovery and recycling system to reduce ink waste. Precise control of ink thickness ensures printing quality and reduces cost at the same time.

5. Multi-functional adaptation, strong compatibility: automatic screen printing machine can be adapted to different materials and specifications, such as glass, metal, plastic, paper, fabric and so on. Can be integrated with other automated equipment (such as dryers, UV curing machine), forming an integrated printing production line.

Third, the application areas of automatic screen printing machine

1. Electronic and electrical appliances industry: widely used in cell phone buttons, glass panels, circuit boards, electronic components and other patterns and logo printing. Realize high-precision printing and automatic mass production to ensure product consistency.

2. Packaging and labeling industry: applied to plastic bottle caps, metal cans, boxes, labels and signs and other printing. To achieve clear patterns, bright colors, strong adhesion of the screen printing effect.

3. Textile and clothing industry: applied to T-shirts, fabrics, handbags and other fabrics printing. The equipment supports multi-color automatic overprinting, beautiful patterns and high printing efficiency.

4. Automobile and home appliance industry: used for automobile dashboard, window logo, home appliance panel and other parts of the logo and decorative printing. High printing precision and strong wear resistance meet the durability needs of the automobile and home appliance industry.

5. Crafts and advertising industry: applied to metal nameplates, glass products, plastic billboards and other products pattern printing. Realize batch production and high quality printing, enhance the competitiveness of the product market.

Fourth, the future development trend of automatic screen printing machine

1. High precision and micro-fine printing: With the development of microelectronics and nanotechnology, automatic screen printing machine will be able to achieve finer micro-pattern printing to meet the production needs of high-end electronic components. Precision can be increased to within ± 0.05mm, suitable for high-end electronics, semiconductor and other industries.

2. Intelligent and automated integration: automatic screen printing machine will further integrate with industrial Internet of Things (IoT) and 5G technology to realize remote monitoring and intelligent scheduling. Through big data analysis, printing parameters will be optimized to improve production efficiency and stability.

3. Environmental protection, energy saving and green printing: future equipment will adopt energy-saving design and environmentally friendly ink, reducing solvent use and environmental pollution. Low-temperature curing and high-efficiency drying technology to reduce energy consumption and improve printing efficiency.

4. Multi-functional integrated design: automatic screen printing machine will be integrated production line development, to achieve automatic printing, drying, testing and packaging and other processes integrated to enhance the level of automation. Support rapid plate changing and multi-specification printing to meet the needs of personalized production.

As a highly efficient, accurate and automated screen printing equipment, automatic screen printing machine has become an important tool for modern industrial printing. It can not only significantly improve production efficiency and reduce labor costs, but also ensure the stability of printing quality to meet the needs of mass production. With the continuous promotion of intelligent manufacturing and green trend, automatic screen printing machine will continue to innovate and upgrade in the future, bringing more efficient, more environmentally friendly and more accurate solutions for the printing industry.