Release Date:2025-03-19 15:53:38 Popularity:

In the modern industrial manufacturing field, efficiency, quality and cost control have become the core elements of enterprise competition. Traditional manual production mode due to low efficiency, unstable quality, labor costs and other defects, it is difficult to meet today's market demand for large-scale, high-precision and high-performance production. Fully automated production line as a set of automation, intelligence and high efficiency in one of the advanced production mode, is widely used in various industries, and become an important symbol of intelligent manufacturing.

First, the definition and working principle of automatic production line

1. Definition: Fully automated production line refers to the production system composed of a series of automated equipment and control system without or very little human intervention. It realizes automatic feeding, processing, assembling, testing, packaging and output of finished products through manipulators, conveyors, automatic testing equipment, robots and PLC control system.

2.Working Principle

The operation process of fully automatic production line usually includes the following steps:

Automatic feeding and conveying: the raw materials are fed into the processing equipment through belt, chain plate, roller conveyor line or robot.

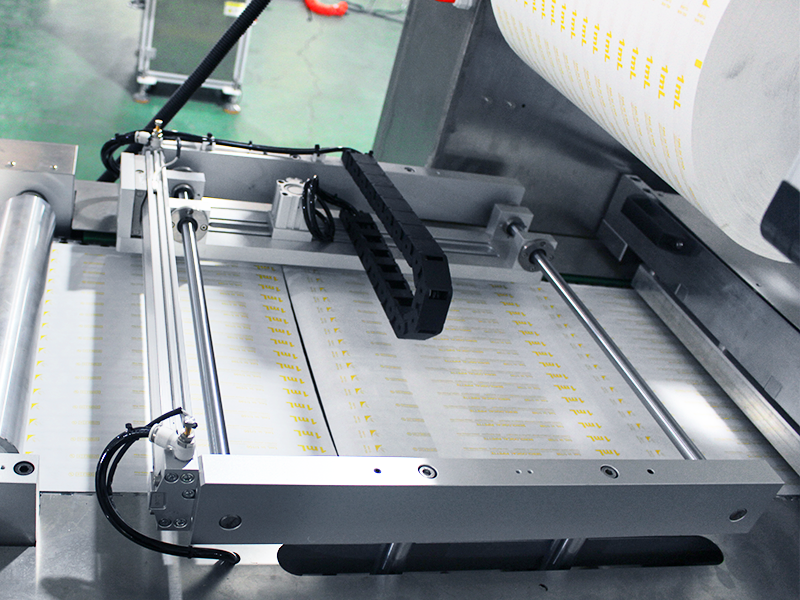

Automatic processing and assembly: robots or automatic equipment on the production line in accordance with the preset program to carry out precise processing or assembly processes.

Automatic inspection and quality control: Visual inspection system, laser scanning or sensors are used to inspect the quality of products and automatically reject defective products.

Automatic Packaging and Palletizing: Qualified products are packaged by automatic packaging machines and palletized and stacked by robots.

Intelligent control and data management: PLC or MES system monitors the production status in real time, collects data and optimizes the production process.

Second, the core advantages of automatic production line

1. Improve production efficiency and reduce labor costs: Fully automatic production line can work continuously without human intervention, which greatly improves production efficiency. A single production line can realize 24-hour uninterrupted operation, significantly reducing labor input. Reduce manual operation, reduce labor intensity, while avoiding human error.

2. Stable product quality and improved yield rate: the equipment ensures the consistency of the production process and reduces quality fluctuations through precise control and automatic inspection. The automatic inspection system eliminates defective products and improves the qualified rate and quality stability of finished products.

3. Intelligent management, real-time monitoring and data tracking: The fully automatic production line adopts intelligent monitoring system to collect and analyze production data in real time. Through MES or ERP system to achieve data tracing, quality management and production efficiency optimization.

4. Reduce cost and material waste: automated operation reduces raw material waste and optimizes material use efficiency. Long-term operation can reduce labor and management costs and improve the overall efficiency of the production line.

5. Strong flexibility and expandability: the configuration can be adjusted according to the production demand and market changes, flexibly adapting to the production of different specifications and varieties. Support modular expansion and transformation, easy to upgrade and maintenance.

Third, the application areas of automatic production line

1. Food and beverage industry: applied to the automated production of mineral water, beverages, milk, juice, recreational food and so on. Including automatic filling, capping, labeling, packaging and testing and other integrated production processes. Ensure food hygiene and quality, while improving production efficiency and packaging precision.

2. Pharmaceutical and medical device industry: the automatic production line is widely used in the fields of pharmaceutical filling, capsule filling, medical swab assembly, test kit packaging and so on. It realizes precise filling, aseptic operation and automatic quality inspection, which is in line with GMP standard. Improve production efficiency, ensure the quality and consistency of drugs.

3. Automotive and electronics industry: applied to automotive parts, electronic components, home appliances, automatic assembly and testing. Adopt automatic welding, assembly, testing and packaging process to ensure product quality and production efficiency. Realize flexible production, adapt to the multi-species, small batch customization needs.

4. Hardware and machinery industry: applied to automatic processing and assembly of metal parts, fasteners, hardware tools. Automated equipment to achieve high-precision processing and testing to ensure product consistency. Reduce manual operation, improve production efficiency and precision.

5. Packaging and logistics industry: automatic production line is widely used in the field of logistics sorting, packaging and palletizing. Realize automatic sorting, sealing, labeling and packing, improve logistics efficiency and accuracy. Integration with AGV robots and intelligent warehousing systems to achieve unmanned intelligent logistics.

Fourth, the future development trend of automatic production line

1. Intelligent and Internet of Things: fully automatic production line will be integrated with industrial Internet of Things (IoT) and 5G technology to achieve remote monitoring and intelligent management. The equipment will have self-diagnosis, self-repair and data tracking functions to further improve production stability.

2. Flexible and multi-functional production: the future fully automated production line will be more flexible and scalable to support multi-species, small batch production. Through rapid mold change and automatic adjustment to meet the demand for personalized customization.

3. Energy saving, environmental protection and green manufacturing: the use of energy-saving motors and environmentally friendly materials to reduce energy consumption and pollution. Introduce clean production technology to realize green intelligent manufacturing.

4. Integration and unmanned: The fully automatic production line will be integrated with AGV intelligent logistics, automatic inspection and sorting system to realize the unmanned process. Further improve production efficiency and reduce labor costs.

As an important part of intelligent manufacturing, the fully automatic production line, with its advantages of high efficiency, precision, automation and intelligence, has been widely used in food, medicine, electronics, automotive, hardware and other fields. It not only significantly improves production efficiency and product quality, but also reduces labor costs and material waste. In the future, with the development of artificial intelligence, Internet of Things and flexible manufacturing technology, the fully automated production line will be more intelligent, flexible and green, which will bring more changes and development power for modern industrial manufacturing.