Release Date:2025-03-11 11:26:18 Popularity:

In the modern printing industry, fully automatic screen printing machine is widely used in the printing needs of all kinds of materials by virtue of its high efficiency, precision and stability. With the development of science and technology, the traditional manual screen printing is gradually replaced by automated equipment, which promotes the printing industry to the intelligent and standardized direction. In this paper, we will discuss the working principle of automatic screen printing machine, the main features and its application in various industries.

First, the working principle of automatic screen printing machine

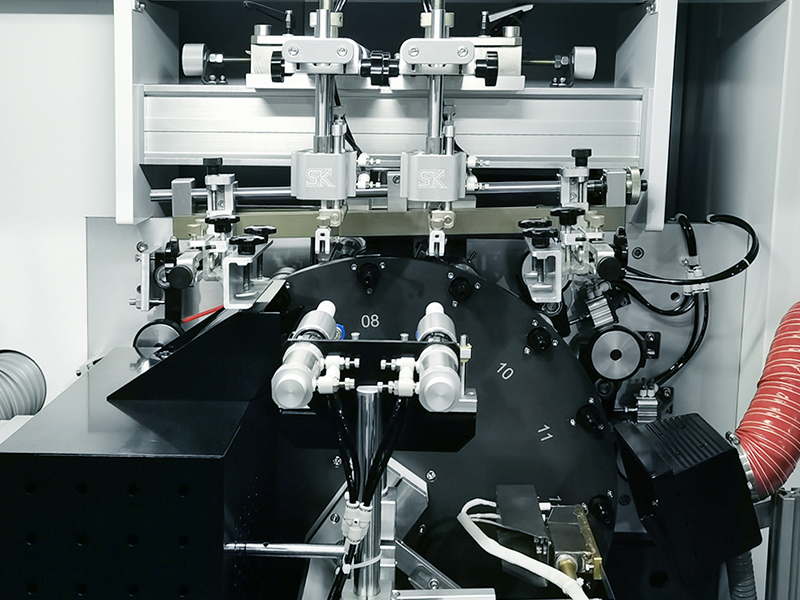

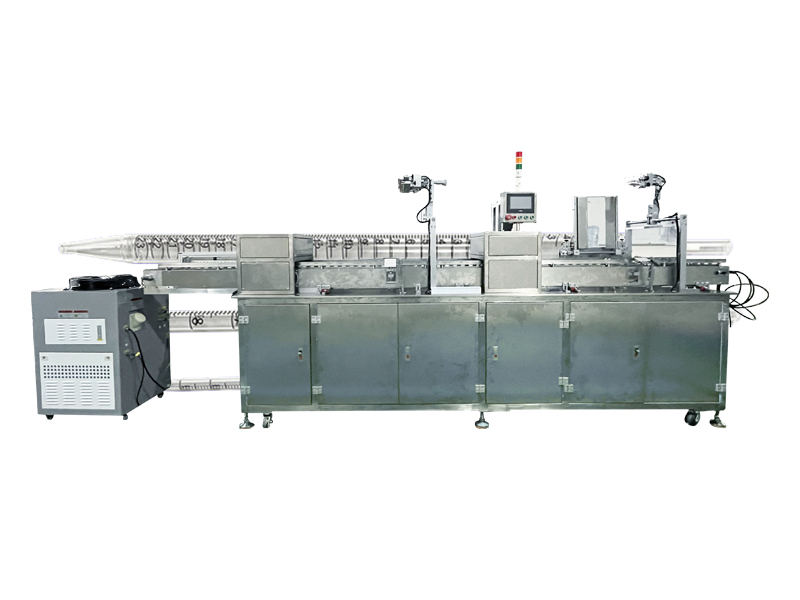

Screen printing is a use of screen templates to transfer ink to the substrate printing method. Automatic screen printing machine in the traditional process, based on mechanical, electrical and computer control technology, to achieve automatic feeding, alignment, printing, drying and receiving a series of operations, greatly improving production efficiency and printing quality.

Its basic workflow is as follows:

1. Feeding: The automatic feeding system conveys the materials to be printed to the working table.

2. Alignment: The photoelectric sensor or camera system is used for precise alignment to ensure the accurate position of the printing pattern.

3. Printing: The squeegee applies pressure evenly under mechanical control and transfers the ink to the substrate through the screen.

4. Drying: The ink is cured quickly by ultraviolet (UV) curing or hot air drying.

5. Receiving: the finished product is sent to the receiving area through the automatic transfer device, completing the whole printing process.

Second, the main features of automatic screen printing machine

1. High-precision printing: Adopting advanced alignment system and servo control technology to ensure that the printing precision reaches the micron level.

2. High degree of automation: from loading to receiving, the whole process is automated, greatly reducing manual intervention and improving production efficiency.

3. Wide range of application: it can be applied to a wide range of materials such as glass, plastic, metal, ceramics, paper, etc. to meet the needs of different industries.

4. High durability: Made of high-quality wear-resistant materials, the equipment has a long service life and low maintenance costs.

5. Environmental protection and energy saving: some models are equipped with environmental protection ink and energy consumption optimization system, reducing pollution and energy consumption in the production process.

Third, the application areas of automatic screen printing machine

1. Electronic industry: play an important role in circuit board (PCB), touch screen, flexible circuit (FPC) and other products in the pattern printing.

2. Glass industry: widely used in automotive glass, appliance glass, architectural glass decoration and functional printing.

3. Packaging industry: It is used in the pattern printing of plastic bottles, paper boxes, metal cans and other packaging materials to improve the aesthetics and brand recognition of products.

4. Textile industry: used in T-shirt, canvas bag, shoe uppers and other textile pattern printing, to provide high wash-resistant, colorful printing effect.

5. Home appliance and panel industry: used for printing keys and logos on panels of refrigerators, washing machines, microwave ovens and other home appliances, ensuring wear-resistant and clear patterns.

With the continuous progress of intelligent manufacturing technology, fully automatic screen printing machine is developing in the direction of higher precision, more intelligent and more environmentally friendly. In the future, the equipment will further integrate Artificial Intelligence (AI) and Industrial Internet (IoT) technologies to realize remote monitoring, intelligent fault diagnosis and adaptive adjustment. In addition, the promotion of environmentally friendly water-based ink and UV curing technology will help the screen printing industry to move towards a more green and sustainable development path.

The popularization of fully automatic screen printing machines has brought revolutionary changes to the printing industry. Its high efficiency, high precision and multi-functionality make it occupy an important position in many industries. In the future, with further breakthroughs in intelligent, environmentally friendly technology, automatic screen printing machine will continue to promote the printing industry to a higher level of development, creating greater economic value for enterprises.