Release Date:2025-03-10 15:55:19 Popularity:

With the development of science and technology and the growth of market demand, automatic packaging machine is more and more widely used in food, medicine, chemical, daily necessities and other industries. As the core force of equipment development, manufacturing and supply, automatic packaging machine manufacturers are promoting the entire packaging industry to the intelligent, automated and efficient direction. Automatic packaging machine can replace the traditional manual packaging methods, improve production efficiency, reduce costs, and ensure product quality and stability, so by the market's high attention.

First, the type of automatic packaging machine

There are many types of automatic packaging machines, according to different packaging needs, can be divided into the following categories:

1. Granule Packaging Machine: Used for packaging granular materials such as candy, nuts, spices, feed, etc. It adopts quantitative weighing technology to ensure the accuracy of each bag of products.

2.Powder Packaging Machine: It is suitable for powdery materials such as flour, milk powder, coffee powder, medicine powder, etc. It adopts spiral metering method to ensure accurate filling.

3.Liquid Packaging Machine: Suitable for soy sauce, beverage, juice, detergent and other liquid products, featuring no dripping and good sealing.

4. Bag packing machine: suitable for nuts, frozen food, pet food and other prefabricated bag packaging, to enhance the aesthetics and efficiency of packaging.

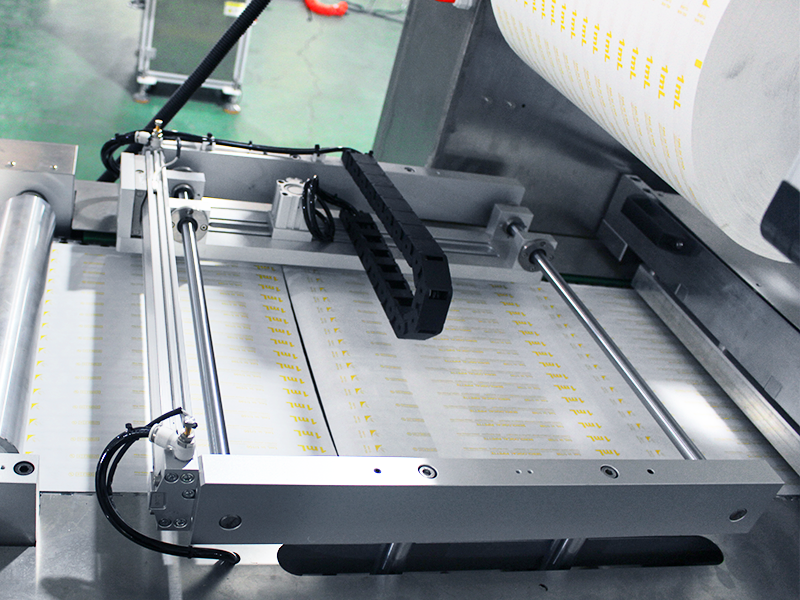

5. Pillow packaging machine: mainly used for food, daily necessities packaging, such as cookies, bread, medical masks, etc., packaging speed, adaptability.

Second, the automatic packaging machine manufacturers of technological innovation

Automatic packaging machine manufacturers of technological innovation is the key to the development of the industry. In recent years, packaging equipment toward the intelligent, automated, environmentally friendly direction, mainly reflected in the following aspects:

1. Intelligent control: the use of PLC control system, human-machine interface operation, so that the packaging process is more accurate and efficient, and remote monitoring and data analysis.

2. High-precision measurement: through weighing sensor, photoelectric detection and other technologies, to ensure that the packaging weight meets the standard and reduce material waste.

3. Multi-functional integration: modern automatic packaging machine can realize the integrated operation of automatic feeding, filling, sealing, marking, detecting, rejecting, etc., reducing manual intervention.

4. Environmental protection and energy saving: the new packaging machine adopts energy-saving motor, biodegradable packaging materials, non-polluting sealing technology, in line with the sustainable development trend.

Third, how to choose the right automatic packaging machine manufacturers

When choosing automatic packaging machine manufacturers, companies need to focus on the following aspects:

1. Manufacturer strength: examine the manufacturer's production scale, technical research and development capabilities, market reputation and whether it has the relevant industry qualifications.

2. Product quality: check the core components of the equipment, production materials, operational stability, and whether it meets industry standards.

3. After-sales service: high-quality after-sales service can guarantee the long-term stable operation of the equipment, including equipment installation, operation training, maintenance and other support.

4. Cost-effective: comprehensive consideration of the performance of the equipment, price and long-term cost of use, choose the most suitable for their needs packaging equipment.

In the future, automatic packaging machine manufacturers will continue to develop in the direction of intelligence, modularity and customization to meet the production needs of different enterprises. At the same time, with the addition of AI technology, automatic packaging machines will achieve self-adaptive optimization to improve production efficiency and quality control. In addition, green packaging technology will become an industry hotspot, promoting the development of packaging equipment in the direction of low energy consumption and degradability.

Automatic packaging machine manufacturers play a vital role in the modern manufacturing industry. With the continuous progress of science and technology, automatic packaging machine will further optimize the production process, improve production efficiency, reduce labor costs, and help enterprises to occupy a favorable position in the market competition. For enterprises, choosing the right automatic packaging machine manufacturers can not only improve productivity, but also promote industrial upgrading and achieve sustainable development.