Release Date:2025-03-08 15:46:24 Popularity:

With the progress of science and technology and the development of industrial automation, there is a growing demand for the production and packaging of laboratory consumables. As a kind of intelligent equipment specialized in packing of pipette tips (pipette tips), the automatic core stuffing cartoning machine for pipette tips plays an important role in the laboratory consumables industry. This equipment integrates multiple processes such as automatic collating, core stuffing, cartoning, sealing, etc., which greatly improves the production efficiency and reduces the labor cost at the same time. In this article, we will introduce the working principle, application areas and advantageous features of the suction head automatic core stuffing cartoning machine.

First, the working principle of suction head automatic core stuffing cartoning machine

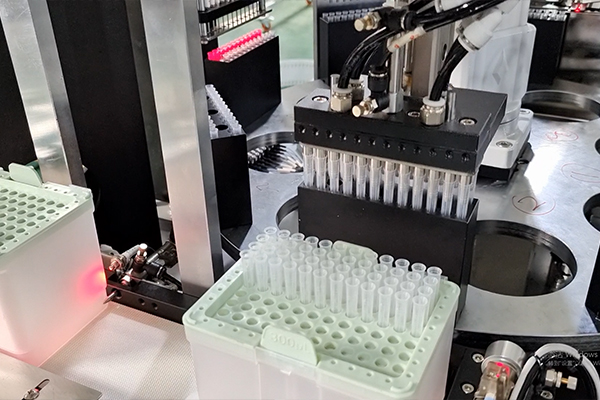

Suction head automatic core filling and cartoning machine is a kind of packaging equipment based on automatic control system, which is mainly composed of feeding system, material management device, core filling device, cartoning mechanism, sealing mechanism and intelligent control system. Its workflow is as follows:

1. Automatic feeding: the suction head is orderly transported to the specified position through vibrating plate or conveyor belt, and is automatically arranged.

2. Neat material sorting: the machine has built-in precision robot or vacuum adsorption system to arrange the suction heads and ensure that they are accurately put into the packing box.

3. Automatic core stuffing: The system will stuff the fixed number of tips into the box firmly through precise pneumatic or mechanical mechanism to avoid breakage or shift.

4. Cartoning and sealing: After filling, the machine automatically folds the box and seals it, completing the whole cartoning process.

5. Quality inspection and discharging: some high-end equipment is also equipped with photoelectric detection system, which can detect whether the cartoning is qualified or not, unqualified products will be rejected, and qualified products will be conveyed to the finished product area.

Application fields of automatic cartoning machine for pipette tips

This equipment is widely used in the laboratory consumables manufacturing industry, suitable for biological laboratories, pharmaceutical companies, medical equipment production plants. The main packaged products include:

Pipette gun tips: Pipette gun tips of different specifications, such as 10μL, 200μL, 1000μL, etc.

PCR tubes and centrifuge tubes: consumables packaging for molecular biology experiments.

Other small plastic laboratory consumables: such as freezing storage tubes, cuvettes, etc.

Third, the advantages of pipette tip automatic core stuffing cartoning machine

1. High efficiency and stability: the automated process can realize high-speed packaging, reduce manual intervention and improve production efficiency.

2. High accuracy: advanced robot and photoelectric detection system ensure that each pipette tip can be accurately filled into the box, reducing loss.

3. Reduced labor costs: Compared with the traditional manual cartoning method, the equipment reduces the need for a large number of manual operations, reducing labor costs.

4. High hygiene standard: the equipment is made of stainless steel and food-grade materials, which conforms to GMP (Good Manufacturing Practice) standards and ensures the hygiene and safety of the products.

5. Strong compatibility: It can be adapted to different specifications of suction head packaging, and part of the equipment also supports quick change of molds, realizing multi-purpose use of one machine.

6. Intelligent control: Equipped with PLC intelligent control system, it is easy to operate and supports data monitoring and remote maintenance, which improves the reliability of the equipment.

Fourth, the market outlook and development trend

With the growing global demand for laboratories and the rapid development of the medical and biotechnology industries, the demand for automated packaging of laboratory consumables is also on the rise. In the future, the pipette tip automatic core stuffing cartoning machine will continue to be optimized in the direction of intelligence, unmanned, green and environmental protection.

1. Intelligent upgrading: In the future, the equipment will further integrate AI algorithms, optimize the packaging process, and improve the self-adaptive ability of the equipment.

2. Unmanned production: Combined with robots and automatic handling systems, real unattended production.

3. Green environmental protection: the use of biodegradable packaging materials, reducing energy consumption in the production process, in line with environmental requirements.

Tip automatic core stuffing cartoning machine is an important automated equipment for the production of modern laboratory consumables, which improves the production efficiency, reduces the labor cost and ensures the hygiene and safety of the products through the efficient and precise packing method. With the increasing market demand and the continuous upgrading of technology, this equipment will play an increasingly important role in the laboratory consumables industry. In the future, with the further development of intelligent technology, the pipette tip automatic core stuffing cartoning machine will usher in a broader market prospect.