Release Date:2025-03-07 16:01:38 Popularity:

With the arrival of the industry 4.0 era, the manufacturing industry is gradually moving towards intelligence and automation. Under this trend, automated manufacturing production line has become an important tool to promote industrial upgrading. It not only improves production efficiency, but also reduces production costs, improves product quality, and helps enterprises to take advantage of the fierce market competition.

First, the definition of automated manufacturing line

Automated manufacturing production line refers to the production process using a variety of automated equipment, robots and intelligent control systems to replace manual material handling, assembly, processing, testing, packaging and other processes of the production system. This kind of production line can realize the whole process of automation or semi-automation operation, which greatly improves the production efficiency and accuracy.

Second, the advantages of automated manufacturing line

1. Enhance production efficiency: the traditional manual production model is limited by the efficiency of the personnel, while the automated production line is able to operate continuously and efficiently, significantly increasing production capacity.

2. Reduce production costs: by reducing the dependence on labor, enterprises can effectively reduce labor costs, while reducing losses due to human error, improve material utilization.

3. Enhance product quality: The automated production line adopts precision control system and high-precision equipment to ensure the stability of product quality and reduce the rate of defective products.

4. Enhance production safety: the automation of the production line reduces the possibility of workers contacting dangerous equipment, improves the safety of the workshop, and reduces the incidence of industrial accidents.

5. Realize flexible production: modern automated production line can be adjusted through the program to achieve multi-species, small batch production to meet the diverse needs of the market.

Third, the application of automated manufacturing line

1. Automobile manufacturing: automated production lines are widely used in automobile manufacturing, including welding, spraying, assembly and other links, significantly improving production efficiency.

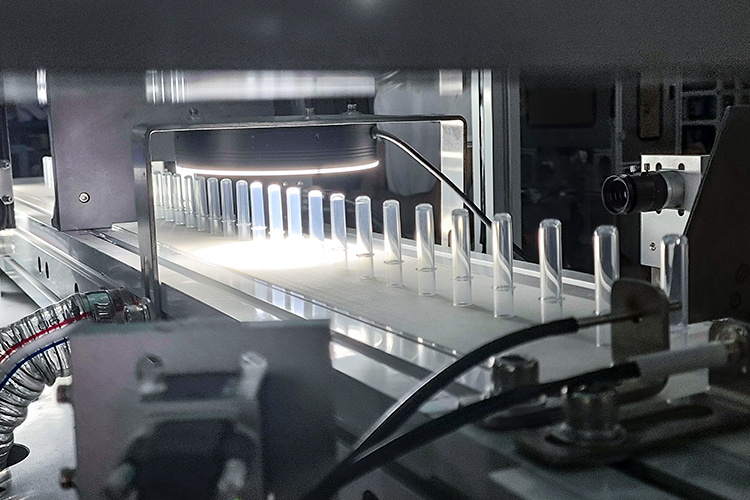

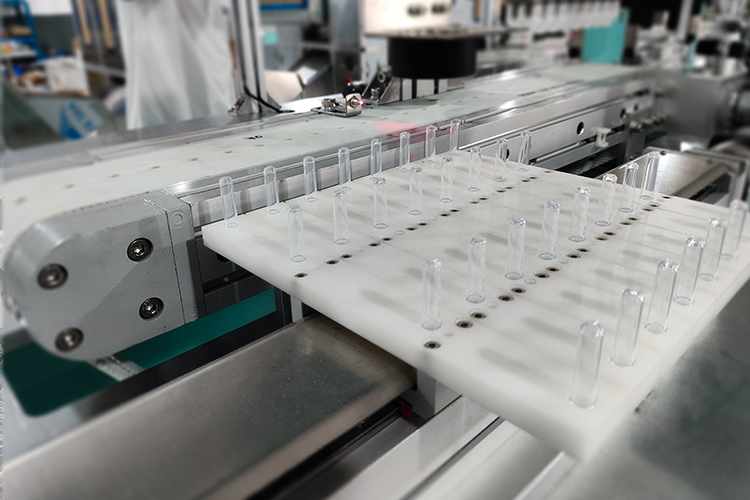

2. Electronic product manufacturing: the production of smart phones, home appliances, computers and other electronic products requires high precision, automated production lines can ensure accurate control of each link.

3. Food and pharmaceutical industry: food processing and pharmaceutical manufacturing industries require a highly hygienic and safe production environment, automated production lines can effectively avoid human contamination to ensure product safety.

4. Packaging industry: modern packaging industry widely used automation equipment, such as automatic filling, sealing, labeling and packaging equipment to improve production efficiency and packaging precision.

Fourth, the future development trend

With the development of artificial intelligence, Internet of Things and big data technology, the automated manufacturing production line is moving towards intelligence and digitalization. In the future, it will realize the depth of application in more industries, further improve production efficiency and promote industrial upgrading. For enterprises, investment in automated manufacturing production line is not only the key to enhance competitiveness, but also an inevitable choice to adapt to future market development.

Automated manufacturing line is becoming the core driving force of modern industrial production. With the continuous progress of technology, enterprises should actively introduce automated production lines to improve production efficiency, reduce costs, and meet the growing market demand for personalization. In the future, automated manufacturing production line will continue to promote the manufacturing industry to intelligentization and digitalization, bringing new opportunities and challenges for global industrial development.