Release Date:2025-03-06 15:54:57 Popularity:

With the continuous progress of science and technology, automated production equipment is increasingly widely used in various industries. Whether it is food processing, pharmaceutical manufacturing, or electronic assembly, automotive manufacturing, automated production equipment plays a vital role. It not only improves production efficiency, but also reduces labor costs and ensures the stability of product quality. This article will focus on the definition of automated production equipment, advantages, application areas and future development trends.

What is automated production equipment?

Automated production equipment refers to the use of mechanical, electrical, computer and intelligent control technology to realize the automation of the production process equipment. It includes a variety of automated assembly lines, robots, CNC machine tools, intelligent testing equipment and so on. Through preset programs or artificial intelligence control system, these equipments can efficiently and accurately complete various production tasks, reduce manual intervention and improve production stability.

Advantages of automated production equipment

1. Improve production efficiency: traditional manual production methods are limited by the speed and working time of human labor, while automated production equipment can work continuously without rest, thus significantly improving production efficiency.

2. Reduce labor costs: automated equipment can replace a large number of manual operations, reducing the enterprise's dependence on human resources, especially in the case of rising labor costs, automated production equipment can effectively reduce operating costs.

3. Ensure the stability of product quality: manual operation may lead to product quality instability, while automation equipment through precision control technology to ensure the standardization and consistency of each production step, reduce the rate of defective products, improve product quality.

4. Improve production safety: In some high-risk industries, such as chemical, metallurgical and mining operations, automation equipment can replace manual labor to complete dangerous operations, reduce the risk of injury to workers and improve production safety.

5. Flexible production, improve adaptability: modern automation equipment to support the production of a variety of products to switch, can quickly adjust the production parameters to adapt to the production of different products to meet the market's individual needs.

Application areas of automated production equipment

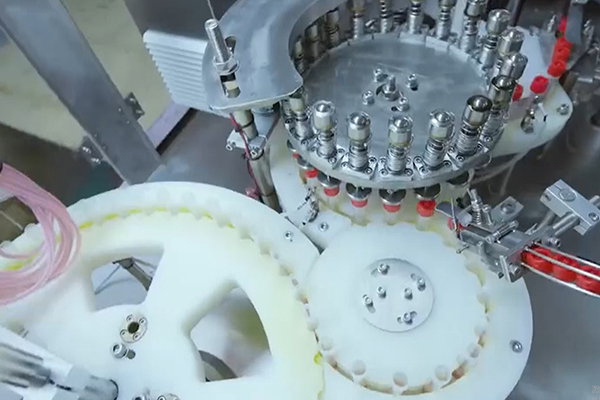

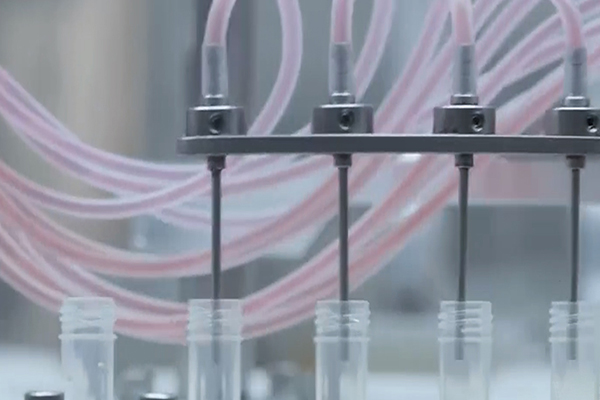

1. Food and beverage industry: modern food processing plants are widely used automation equipment, such as automatic packaging machines, filling machines, sorting machines, etc., to improve production efficiency and ensure food safety.

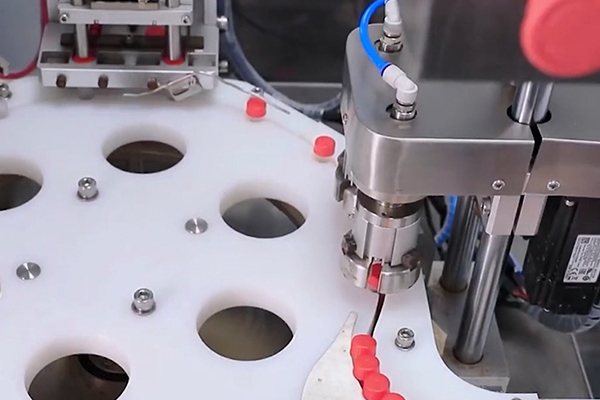

2. Pharmaceutical industry: automated production equipment plays a key role in the pharmaceutical manufacturing and packaging process, such as capsule filling machines, pharmaceutical packaging machines, automatic packaging systems, etc., to improve the accuracy and safety of drug production.

3. Electronic manufacturing industry: automation equipment in the electronics industry covers the PCB circuit board assembly, chip packaging, automatic welding, testing and other aspects of improving the production efficiency and quality of electronic products.

4. Automobile manufacturing industry: robot welding, automatic spraying, intelligent assembly and other automation technology in the automobile manufacturing industry has become the mainstream, improving production efficiency and reducing labor errors.

5. Chemical and packaging industry: the production of many chemical and packaging products relies on automation equipment, such as powder packaging machine, granule packaging machine, liquid filling machine, etc., to make the production process more efficient and accurate.

The future development trend of automated production equipment

1. Intelligent and artificial intelligence combined: with the development of artificial intelligence (AI) technology, automation equipment will be more intelligent, can learn independently, optimize the production process, and improve the adaptive ability of the equipment.

2. Application of Internet of Things (IoT) technology: future automation equipment will pay more attention to data collection and interconnection, and realize remote monitoring, predictive maintenance and intelligent decision-making through IoT technology, so as to improve the utilization rate and reliability of equipment.

3. Green and energy saving: a new generation of automated production equipment will pay more attention to energy efficiency and environmental performance, using low energy consumption, high efficiency production methods, reduce industrial pollution.

4. Personalized and customized production: In the future, automation equipment will play a greater role in personalized and customized production, enterprises can quickly adjust the production model to meet the needs of different customers.

Automated production equipment is an important direction of industrial development, it not only improves production efficiency, reduce costs, but also promote the manufacturing industry to intelligent, efficient and green direction. With the continuous progress of science and technology, the application of automated production equipment will be more extensive, providing strong technical support for the development of various industries.