Release Date:2025-02-17 15:50:20 Popularity:

With the continuous development of science and technology, industrial production is moving towards the direction of intelligentization and automation. Under this trend, fully automatic intelligent production line has become an important tool for major manufacturing enterprises to improve production efficiency, reduce costs and improve product quality. Fully automatic intelligent production line combines artificial intelligence, Internet of Things, industrial robots and other advanced technologies to realize the automation and intelligent management of the whole production process, which has brought revolutionary changes to the modern manufacturing industry.

First, the concept and composition of automatic intelligent production line

Fully automatic intelligent production line is a highly integrated automated production system, which covers raw material handling, production and processing, quality testing, packaging and transportation and other aspects. Its core feature is the use of sensing technology, data analysis and intelligent control system to achieve autonomous adjustment and optimization of production, and improve production efficiency and stability.

The main components include:

1. Automated production equipment: such as CNC machine tools, automatic assembly machines, intelligent welding robots, etc., to realize accurate and efficient production and processing.

2. Intelligent control system: based on PLC (Programmable Logic Controller), SCADA (Data Acquisition and Monitoring System), etc., to realize intelligent control and synergy of equipment.

3. Industrial robots: used for automatic handling, assembly, testing and other tasks to reduce manual intervention and improve production efficiency.

4. Internet of Things and big data analysis: real-time monitoring and optimization of production status through sensors and data acquisition systems.

5. Intelligent inspection and quality control: using machine vision, AI inspection system and other technologies to ensure stable product quality.

Second, the advantages of automatic intelligent production line

1. Enhance production efficiency: under the traditional production mode, the process is cumbersome and relies on manual operation, and the production efficiency is low. Fully automatic intelligent production line can run 24 hours a day, reducing human intervention, greatly improving production efficiency.

2. Reduce production costs: by reducing labor costs, optimizing the use of resources and reducing production losses, fully automatic intelligent production line can effectively reduce production costs and improve corporate profits.

3. Improve product quality: Intelligent equipment can strictly enforce production standards, reduce errors caused by human operation, and improve product consistency and quality stability.

4. Enhance flexible production capacity: modern market demand changes rapidly, automatic intelligent production line has strong flexible manufacturing capacity, can quickly adjust the production process to meet the demand for different specifications and models of products.

5. Optimize the use of energy and reduce waste: through the intelligent control system, optimize energy consumption, reduce the waste of raw materials to achieve green production.

Application areas of automatic intelligent production line

1. Food processing industry: for automated production, packaging, testing, and improve food safety standards.

2. Electronic manufacturing industry: intelligent assembly, chip manufacturing, PCB welding and other aspects of the intelligent production line is widely used.

3. Automobile manufacturing: from body welding, parts assembly to vehicle inspection, all rely on intelligent production lines.

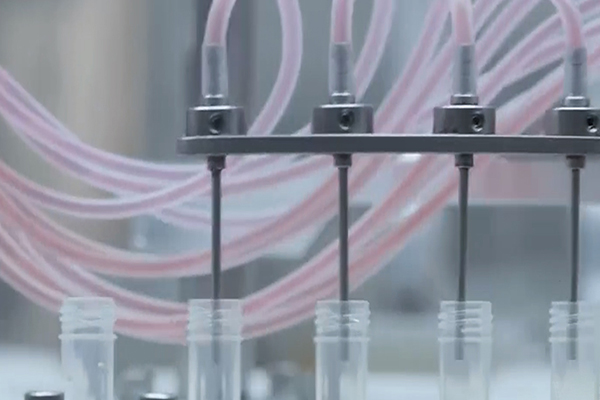

4. Pharmaceutical industry: applied to drug production, filling, packaging, etc., to improve the safety and compliance of drug production.

5. Daily chemical industry: automated production and packaging of cosmetics, detergents, to improve market supply capacity.

Fourth, the development trend of automatic intelligent production line

1. Deep integration of artificial intelligence and machine learning: in the future, fully automated intelligent production lines will apply more AI technology to achieve self-optimization of the production process and intelligent decision-making.

2. The combination of 5G and industrial Internet technology: the high-speed and low-latency characteristics of the 5G network will improve the data transmission efficiency of the production line and make the collaboration between the equipment smoother.

3. Intelligent and flexible production: the future intelligent production line will have stronger flexible manufacturing capabilities, and be able to quickly adapt to changes in market demand and realize customized production.

4. Green manufacturing and sustainable development: energy saving and environmental protection is an important direction for future industrial development, automatic intelligent production line will emphasize more energy saving and emission reduction, and promote the development of green manufacturing.

The popularization and development of automatic intelligent production line not only enhances the competitiveness of the manufacturing industry, but also promotes the process of Industry 4.0. For enterprises, the adoption of intelligent production lines can not only improve production efficiency and product quality, but also reduce costs and achieve a higher level of intelligent management. In the future, with the continuous progress of artificial intelligence, Internet of Things, 5G and other technologies, the fully automatic intelligent production line will be applied in more fields, helping the global manufacturing industry to move towards a new era of intelligence.