Release Date:2024-12-06 16:22:55 Popularity:

With the rapid development of modern industry, the application of automation equipment in the field of packaging has become more and more common, in which the automatic quantitative baling press has become an important tool for enterprises to improve production efficiency and optimize the packaging process by virtue of its high efficiency, precision and intelligent features. This article will focus on the characteristics, advantages and applications of automatic baling press in different fields to discuss in depth.

Definition and working principle of automatic quantitative baler

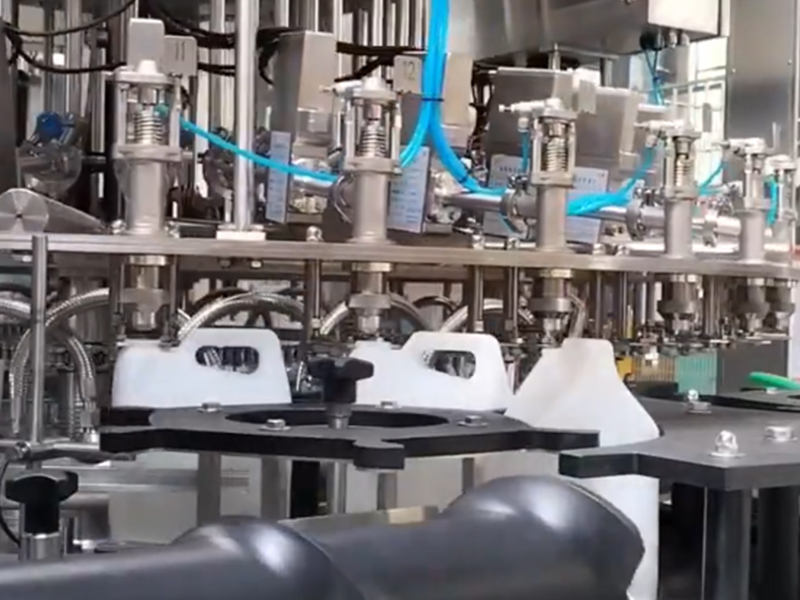

Automatic quantitative baler is a kind of material in accordance with the preset weight for automatic measurement, packaging, sealing equipment. It usually consists of material conveying system, weighing system, packing system and control system. The equipment detects the weight of materials in real time through the collaboration of sensors and controllers to ensure that each bag of products meets the set quantitative standards. During the packaging process, the machine can automatically complete the processes of material conveying, weighing, filling and sealing to realize integrated operation.

Its working principle is to utilize electronic weighing technology combined with PLC (Programmable Logic Controller) for data processing. When the material reaches the set weight, the conveying system automatically stops and transfers the material to the packaging section. This process is not only accurate and reliable, but also can be adjusted according to the parameters of production demand, applicable to different specifications of packaging requirements.

The main advantages of automatic quantitative baler

1. High efficiency: automatic quantitative baler can run continuously, reducing the time of manual operation and greatly improving the production efficiency. Especially in the case of mass production, its automation advantage is particularly significant.

2. Accuracy: with the help of advanced electronic weighing and sensing technology, automatic quantitative baling press can accurately control the weight of each bag of material, the error is usually controlled within ± 0.5%. This high-precision measurement capability reduces raw material waste while ensuring product consistency.

3. Saving labor costs: traditional manual packaging requires a lot of manpower, while the automatic quantitative baling press can realize one person to monitor the operation of multiple devices, significantly reducing labor costs. In addition, automated operation reduces the possibility of human error and improves the overall production efficiency.

4. Wide range of application: automatic quantitative baler can be used for granules, powders, liquids and other materials packaging, such as food, chemical, pharmaceutical, building materials and other fields, to meet the diverse packaging needs.

5. Intelligent operation: modern automatic quantitative baler is usually equipped with touch screen and intelligent control system, the operation is simple and intuitive. Users can set packaging parameters according to production requirements and optimize the equipment through data recording and analysis.

Application Fields

1. Food industry: automatic quantitative balers are widely used in the food field, such as the packaging of rice, flour, sugar, spices and so on. Its high efficiency and hygienic characteristics meet the strict requirements of the food industry for packaging.

2. Chemical industry: in the chemical industry, automatic quantitative baler is used in the packaging of powder and granular chemical products, such as fertilizer, plastic granules and so on. The equipment can adapt to the complex material characteristics, to ensure packaging accuracy.

3. Pharmaceutical industry: Pharmaceutical products require high packaging precision and hygiene standards, automatic quantitative baler can accurately control the weight of drugs to avoid excess or insufficient, improving the quality of drug packaging.

4. Building materials industry: for cement, sand and gravel and other building materials, automatic balers provide efficient and stable packaging solutions, providing strong support for the industry's large-scale production.

With the continuous progress of science and technology, automatic quantitative baler is moving towards a more intelligent and multi-functional direction. For example, the equipment will pay more attention to the human-computer interaction experience, increase the remote monitoring function; at the same time, through the combination of big data and the Internet of Things technology, to realize the digital management of the whole production process. In the future, energy saving and environmental protection is also the focus of development, more green materials and energy-saving design will be integrated into the equipment development.

Automatic Quantitative Baler is an important part of modern industrial automation, and its high efficiency, precision and intelligence play a great role in various industries. With the continuous progress of technology and the expansion of application areas, automatic quantitative baling press will bring more possibilities for enterprises to improve production efficiency and cost optimization. In the future, it will surely become the backbone of the industrial packaging field.