Release Date:2024-12-06 15:54:59 Popularity:

As an indispensable part of modern manufacturing industry, fully automatic assembly machine is widely used in many fields such as electronics, medical, automotive, home appliances and so on by virtue of its high efficiency, precision and stability. This kind of equipment not only improves the production efficiency, but also effectively reduces the errors in manual operation, creating significant economic benefits for enterprises. In this paper, we will discuss the technical principle, application advantages and future development trend of fully automatic assembly machine.

The technical principle of automatic assembly machine

Fully automatic assembly machine is a kind of equipment that utilizes mechanical, electronic control and software technology to realize automatic conveying, positioning, assembling and testing of parts. Its core consists of the following parts:

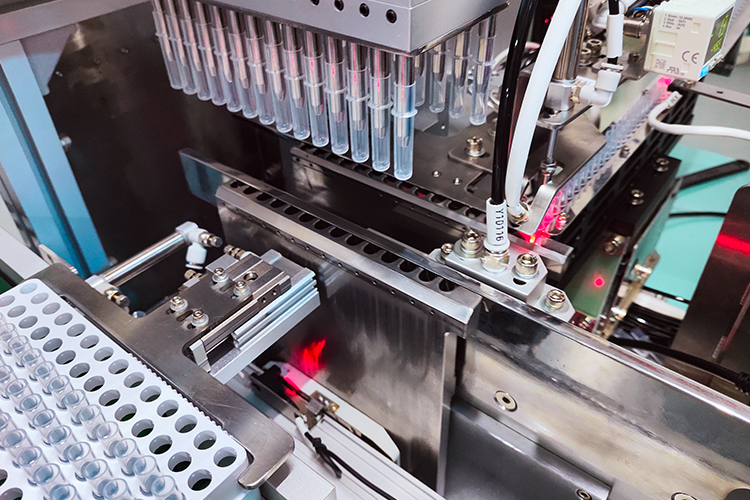

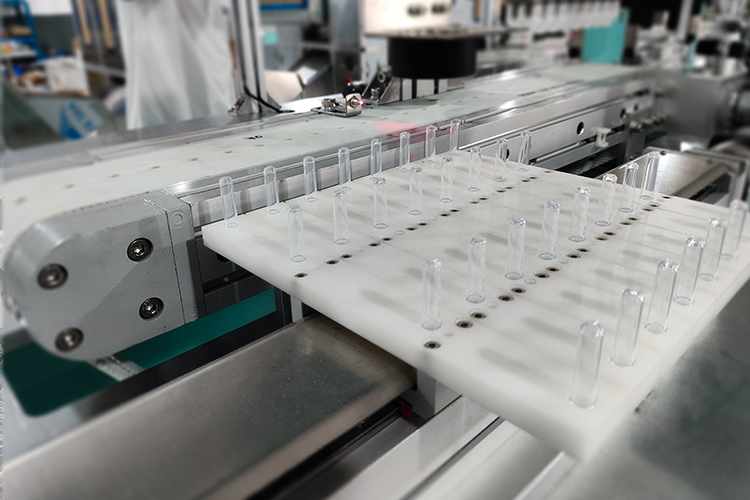

1. Automatic feeding system: Using vibrating plate, belt conveyor or other transmission equipment, the parts are precisely delivered to the specified position.

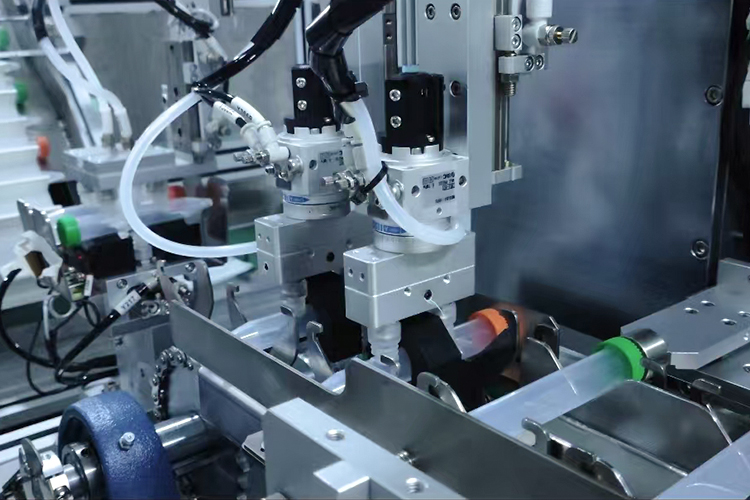

2. Positioning and assembly mechanism: through servo motors, robotic arms and other precision machinery, it completes the gripping, positioning and assembly action of the parts.

3. Intelligent control system: PLC (Programmable Logic Controller), industrial computer or embedded system is used for control to realize multi-task parallel processing.

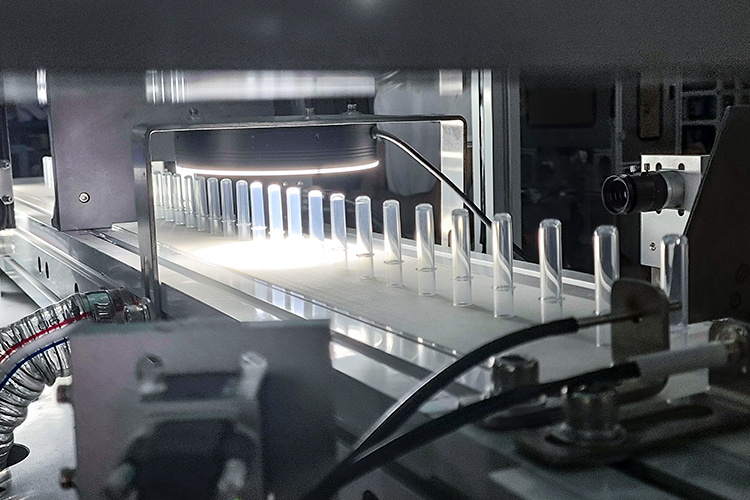

4. Online inspection system: through sensors, cameras and other equipment, real-time monitoring of errors in the assembly process, and feedback adjustment.

5. Human-computer interaction interface: provide operators with convenient equipment debugging, fault diagnosis and parameter setting functions.

Application advantages of fully automatic assembly machine

1. Enhance production efficiency: fully automatic assembly machine can continuously and quickly complete the assembly task, and its efficiency is much higher than the traditional manual operation. This advantage is especially prominent in mass production scenarios.

2. Improve assembly accuracy: through mechanized operation and precise control, fully automatic assembly machine can effectively avoid assembly deviation caused by fatigue or technical limitations in manual operation, thus improving product quality.

3. Saving labor cost: with the rising labor cost, the popularization of automation equipment is especially important. Fully automated assembly machine reduces the dependence on operating workers and saves long-term labor expenses for enterprises.

4. Enhance production safety: In some high-risk, high-intensity assembly tasks, the use of fully automatic assembly machine can avoid workers directly involved in dangerous operations, thus reducing the incidence of safety accidents.

5. Flexibility to adapt to diversified needs: modern fully automatic assembly machines generally support multi-variety switching, through simple software adjustments or replacement of components, can adapt to the production needs of different products, to meet the challenges of rapid changes in the market.

The future development trend of automatic assembly machine

1. Intelligent: with the advancement of artificial intelligence technology, the future fully automatic assembly machine will have higher independent learning and decision-making capabilities. For example, the assembly path and speed will be optimized by deep learning algorithms.

2. Modular design: modularization will become an important trend in the design of fully automatic assembly machines, which will make it easier to upgrade and maintain the equipment, and at the same time improve the versatility of the equipment.

3. Green environmental protection: driven by the concept of sustainable development, fully automatic assembly machine will pay more attention to energy efficiency and material savings, reduce carbon emissions in the production process.

4. Industrial Internet of Things Integration: Fully automated assembly machines will be closely integrated with the Industrial Internet of Things (IIoT) to realize data interoperability between equipment and remote monitoring, and improve production management efficiency.

Fully automatic assembly machine is not only an important embodiment of the development of industrial automation, but also a key tool for enterprises to enhance competitiveness. Through continuous technological innovation and optimization, this equipment will play a role in a wider range of fields, helping the manufacturing industry to move forward in the direction of intelligence and green. In the future, the market demand for fully automated assembly machines will continue to grow, becoming an indispensable part of the modern industrial system.