Release Date:2025-03-01 14:33:29 Popularity:

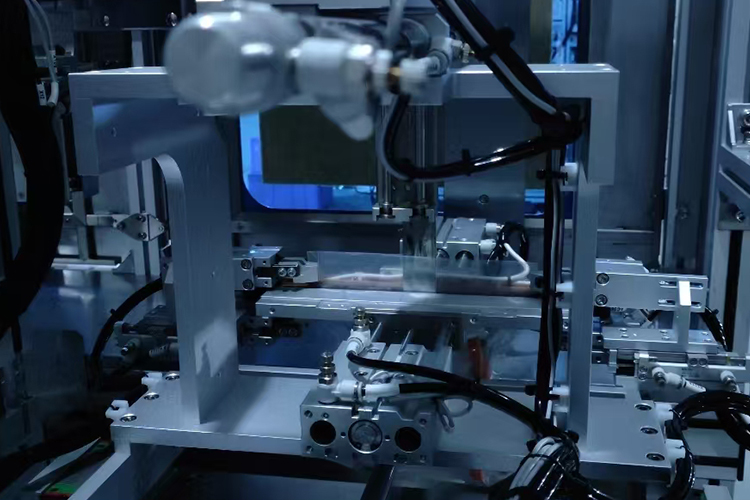

With the continuous progress of industrial automation technology, automated assembly equipment has become an important part of modern manufacturing. It not only improves production efficiency, but also significantly reduces labor costs and ensures the consistency of product quality. In today's increasingly competitive global manufacturing industry, the application of automated assembly equipment has been widely penetrated into the electronics, automotive, medical equipment, home appliances, food packaging and many other industries, for enterprises to bring unprecedented production benefits.

First, the definition and characteristics of automated assembly equipment

Automated assembly equipment refers to mechanical, electronic, sensor, control systems and other technologies, can automatically complete the parts of the assembly, testing, handling, packaging and other processes equipment. This type of equipment is usually composed of PLC (programmable logic controller), servo motors, sensors, robots, conveyor systems and other core components to achieve accurate, efficient and stable assembly tasks.

Its main features include:

1. High efficiency: Compared with the traditional manual assembly method, the automated equipment can run continuously, significantly improving production efficiency.

2. High accuracy: Utilizing precision mechanical control technology to ensure high accuracy and consistency of product assembly.

3. Strong flexibility: the assembly process can be adjusted according to the needs of different products, realizing flexible production.

4. Cost reduction: Reduce the dependence on labor, reduce labor costs, and improve corporate profits.

5. Intelligent monitoring: combined with industrial Internet and data acquisition technology, real-time monitoring of production conditions, improve equipment stability and product quality.

Second, the application field of automated assembly equipment

With the in-depth development of intelligent manufacturing, automated assembly equipment has been widely used in many industries.

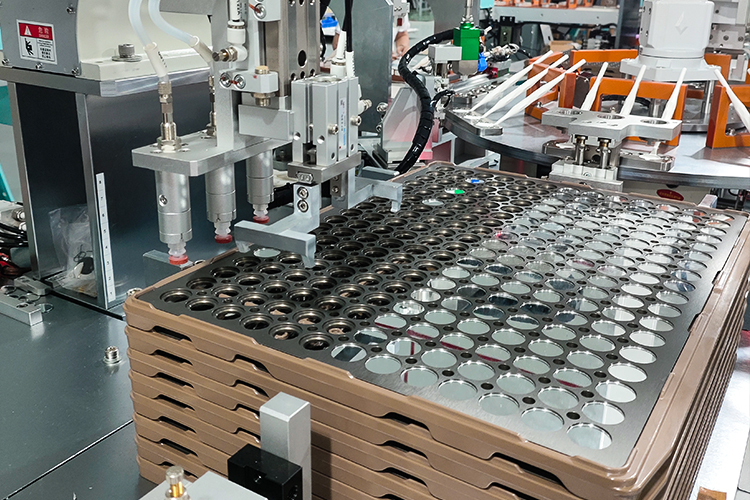

1. Electronic industry: used for smart phones, computers, chips, LED lighting products and other precision electronic components assembly, to ensure product consistency, improve production yield.

2. Automotive industry: automated assembly of engines, transmissions, battery packs and other components to improve production efficiency and ensure the safety and stability of automotive parts.

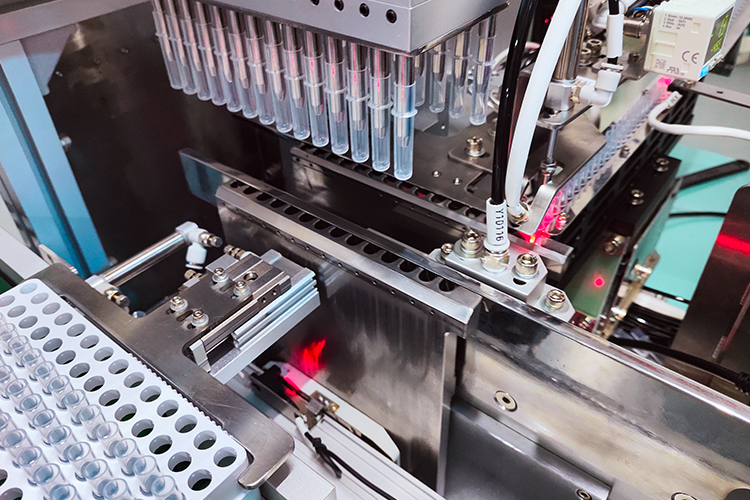

3. Medical equipment industry: high-precision assembly of medical products such as sphygmomanometers, syringes, infusion sets, etc. to meet strict health and quality standards.

4. Home appliance industry: automated assembly of air conditioners, washing machines, rice cookers and other home appliances to improve product quality and reduce production costs.

5. Food packaging industry: automated assembly for food processing and packaging to ensure product safety and improve packaging efficiency.

Third, the development trend of automated assembly equipment

Driven by the global industry 4.0, automated assembly equipment is moving towards the direction of intelligence, flexibility and digitalization.

1. Intelligent upgrading: Combining AI (artificial intelligence) and IoT technology to realize autonomous learning and adaptive adjustment, and improve the intelligent level of equipment.

2. Flexible production: future automated assembly equipment will be more flexible, can quickly adjust the production line according to market demand, to adapt to multi-species, small batch production mode.

3. Human-machine collaboration: collaborative robots combined with automated assembly equipment to achieve efficient and safe assembly operations, improve production efficiency and safety.

4. Green manufacturing: the energy-saving and consumption reduction technology of the equipment is constantly optimized to promote environmentally friendly automated production mode, reduce resource waste and reduce carbon emissions.

Fourth, how to choose the right automation assembly equipment

Enterprises should consider the following factors when choosing automated assembly equipment:

1. Product demand: according to the complexity, size and precision requirements of the product, choose the right type of equipment.

2. Production efficiency: choose the capacity that meets the production needs of the enterprise in order to improve the overall production efficiency.

3. Equipment Stability: Prioritize equipment with reliable quality, low failure rate and easy maintenance to ensure continuous production.

4. Compatibility and expandability: equipment with good compatibility can be adapted to the assembly needs of different products, and support the subsequent upgrading and transformation.

5. After-sales service: choose manufacturers with perfect after-sales support, in order to solve the problems arising during the operation of the equipment in a timely manner.

The wide application of automated assembly equipment has brought manufacturing enterprises a more efficient, accurate and intelligent production mode. Under the wave of industrial automation and intelligent manufacturing, enterprises should actively introduce advanced automation equipment to improve production levels and enhance market competitiveness. In the future, with the integration of AI, 5G, cloud computing and other technologies, automated assembly equipment will usher in a broader development prospect, helping the manufacturing industry to move towards a more intelligent new era.