Release Date:2025-02-20 14:40:01 Popularity:

Fully automatic liquid packaging machine is an indispensable equipment in modern packaging industry, which is widely used in many industries such as food, beverage, pharmaceutical, daily chemical, chemical and so on. With the continuous progress of automation technology, liquid packaging machine in improving production efficiency, reduce labor costs, ensure product quality and enhance the flexibility of the production line plays a huge role. In this paper, we will discuss the working principle of automatic liquid packaging machine, equipment features, application areas and market development trends.

First, the working principle of automatic liquid packaging machine

Automatic liquid packaging machine through a series of automated systems to complete the whole process from liquid filling to sealing, usually consists of the following parts:

1. Automatic feeding system: liquid packaging machine through the feeding system will be liquid materials from the storage container to the filling equipment. Liquid materials according to its type (such as water, beverage, medicinal liquid, etc.) and viscosity, using different conveying methods, such as gravity, pumping or negative pressure.

2. Measuring and filling: the core part of automatic liquid packaging machine is measuring and filling system. Through precise electronic load cell or flow meter, the equipment can accurately measure the amount of liquid in each container to ensure consistent packaging accuracy. For liquids with different viscosities, the equipment can adjust the filling speed and filling volume to meet different production needs.

3. Forming and sealing: after the filling is completed, the bags or bottles will be closed by the automatic sealing device. The sealing methods include heat sealing, pressure sealing, etc. to ensure the sealing of liquid packaging. The quality of sealing directly affects the freshness and appearance of the product, so the precision of the sealing device is crucial.

4. Printing and Packing: Finally, the equipment is usually equipped with a printing device for printing production date, batch number, expiration date and other information on the package. After that, the finished package passes through the conveying system to the next stage, such as crating, stacking or transportation.

Second, the automatic liquid packaging machine equipment features

1. Efficient automation: fully automatic liquid packaging machine is able to complete multiple processes such as filling, sealing and coding of liquid without human intervention. This not only improves the production efficiency, but also reduces the error and cost of manual operation, adapting to the needs of mass production.

2. Precise metering: automatic liquid packaging machine adopts high-precision metering system, which can accurately control the filling amount of each bottle or bag of liquid to ensure the stability and consistency of packaging. Especially in the food and pharmaceutical industries, there are high requirements for metering accuracy, and the accuracy of the equipment greatly improves the qualification rate of the products.

3. Intelligent control system: modern automatic liquid packaging machine is equipped with intelligent control system, the running status of the equipment, production speed, fault alarm and other information can be monitored and adjusted in real time through the touch screen or remote control. In addition, the system can store different packaging parameters, which is convenient to quickly switch the production mode of different products.

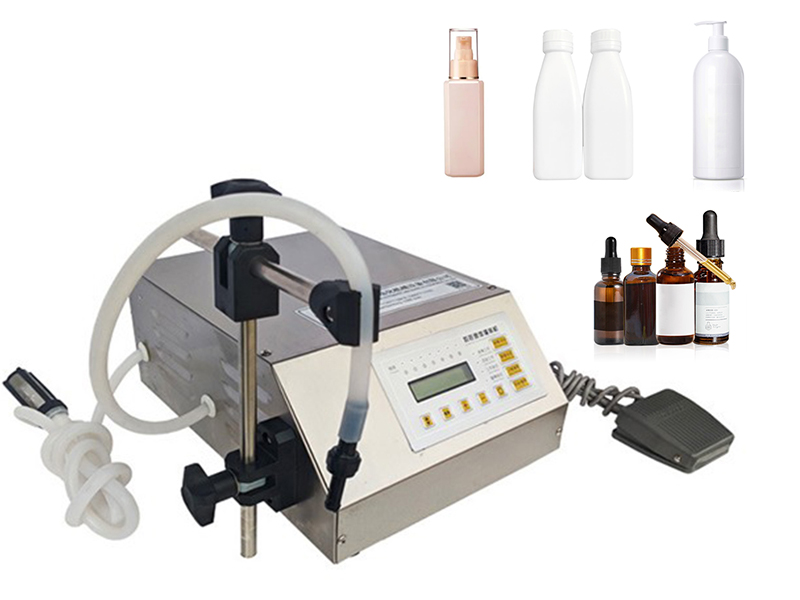

4. Flexible adaptability: The automatic liquid packaging machine can be flexibly adjusted according to the production demand to adapt to different types and specifications of packaging containers, such as bottles, bags, cans and so on. After replacing the mold or adjusting the setting parameters, the equipment can quickly adapt to the packaging of different products, enhancing the flexibility of the production line.

5. Convenient cleaning and maintenance: Liquid packaging machine is usually made of stainless steel, in line with food safety and hygiene standards, smooth surface, easy to clean. Equipment design is simple, easy to carry out maintenance and repair, reducing downtime and extending the service life of the equipment.

Third, the application areas of automatic liquid packaging machine

1. Food and beverage industry: automatic liquid packaging machine is widely used in the packaging of various beverages, such as mineral water, fruit juice, tea drinks, milk, yogurt and so on. The high efficiency and accuracy of the equipment can meet the food and beverage industry on the double requirements of production speed and health standards.

2. Pharmaceutical industry: In the pharmaceutical industry, the packaging of liquid drugs, such as oral liquid, injection, etc. requires precise measurement and aseptic operation. Fully automatic liquid packaging machine can complete the filling and packaging of drugs in aseptic environment, to ensure the safety and stability of drugs.

3. Daily chemical industry: automatic liquid packaging machine is also widely used in shampoo, shower gel, laundry detergent, detergent and other daily chemicals packaging. Its efficient filling and sealing capacity ensures the efficient operation of the production line and meets the demand of mass production.

4. Chemical industry: In the chemical industry, the packaging of liquid chemicals such as lubricants, cleaning agents, paints, etc. also requires the support of automatic liquid packaging machine. The anti-corrosion and high temperature resistant design of the equipment enables it to safely and efficiently package a variety of chemical materials.

Fourth, the market prospects of automatic liquid packaging machine

With the promotion of industry 4.0 and intelligent manufacturing, liquid packaging equipment is moving towards a more intelligent, green and efficient direction. Automatic liquid packaging machine in the future will usher in more market opportunities, especially in the following areas:

1. Intelligent and Internet of Things integration: with the development of the Internet of Things and big data technology, the future of automatic liquid packaging machine will be more intelligent, able to achieve remote monitoring, fault diagnosis, production process optimization and other functions. The equipment can monitor the production data in real time and automatically adjust to achieve the best production results.

2. Environmental protection and energy saving: environmental regulations are becoming increasingly stringent, the future of the liquid packaging machine will use more energy-saving and environmentally friendly design, such as reducing energy consumption, the use of biodegradable packaging materials. Through optimized design, the equipment can reduce material waste, reduce environmental pollution.

3. Flexible production and personalization: With the increase in consumer demand for personalized products, the future of automatic liquid packaging machine will be more flexible production methods, can quickly adjust the equipment settings to adapt to different specifications, different packaging forms of production requirements.

Fully automatic liquid packaging machine as a key equipment in the modern packaging industry, with its high efficiency, precision and intelligent advantages, has become an important part of the production line in many industries. With the continuous progress of technology, the equipment will develop in the direction of more intelligent, environmentally friendly and efficient, promoting the continuous upgrading of the packaging industry. Whether in the food, pharmaceutical, chemical or daily chemical industry, automatic liquid packaging machine will play a greater role in the future production, help enterprises to maintain competitiveness in the fierce market competition.