Release Date:2024-12-09 16:20:19 Popularity:

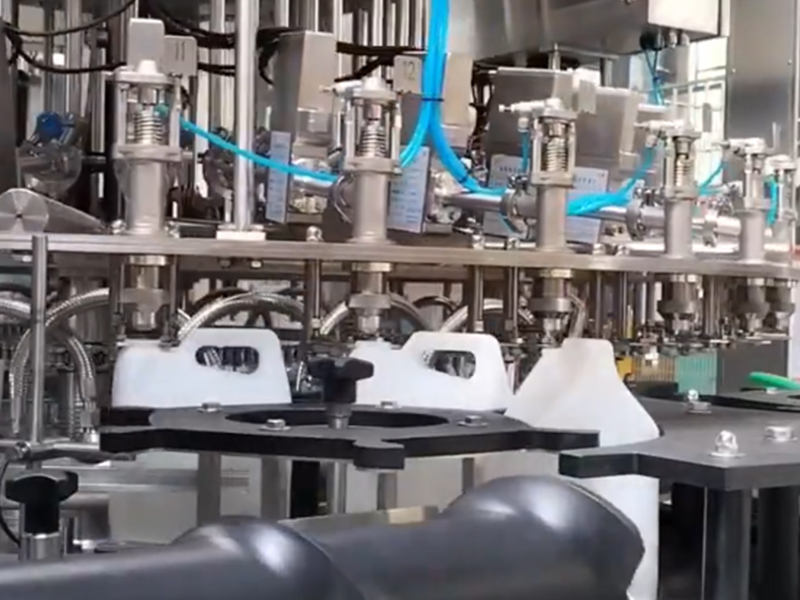

Bottle liquid filling machine is a kind of equipment used for automatic filling of liquid products, which is widely used in food, beverage, cosmetic, pharmaceutical and chemical industries. This kind of equipment with its high efficiency, precision, automation characteristics, become an indispensable and important part of the modern production line. In this paper, we will discuss in detail the core value of the bottle liquid filling machine from the equipment characteristics, application areas, development trends and other aspects.

First, the main features of the bottle liquid filling machine

Bottled liquid filling machine has a variety of advantages, its core features are mainly expressed in the following aspects:

1. Accurate filling: modern bottled liquid filling machine usually adopts high-precision flow meter or electronic weighing technology to ensure that the filling volume of each bottle of liquid reaches the set value, so as to avoid waste or insufficient phenomenon. This high-precision filling capacity is especially suitable for industries with strict requirements on dosage, such as pharmaceutical and cosmetic fields.

2. High degree of automation: the equipment is equipped with an automated control system, including functions such as filling volume setting, bottle identification, liquid flow rate adjustment, etc., which is able to reduce manual intervention and significantly improve production efficiency. Through linkage operation with conveyor belt and packaging equipment, it can also realize streamlined production from filling to packaging.

3. Strong adaptability: the bottle liquid filling machine can handle liquids of different viscosities, from watery beverages to thick sauces with ease. Meanwhile, its filling head and conveying system are usually adjustable, which can adapt to various bottle shapes and capacities.

4. Hygiene and safety: The equipment is made of stainless steel and meets the hygiene standards of the food and pharmaceutical industries. Its filling system generally has an anti-drip design, to avoid contamination caused by liquid overflow in the production process.

Second, the application of liquid bottling machine

Bottle filling machine has a wide range of applications, covering a variety of industries:

-Food and beverage industry: for the production of bottled water, juice, milk and other liquid beverages, but also can be filled with edible oil, seasonings and other liquid food.

-Pharmaceutical industry: In the filling of medicinal liquid, oral liquid, injection liquid and other products, this kind of equipment not only needs to meet the requirements of high precision, but also needs to have the ability of aseptic operation.

-Cosmetic industry: the production of liquid products such as make-up, essence, shampoo, etc. has high requirements on the appearance precision of filling machines and equipment stability.

-Chemical industry: for cleaning agents, lubricants, solvents and other liquid chemicals filling, while the need for equipment with anti-corrosion features.

Third, the development trend of bottle liquid filling machine

With the advancement of science and technology and the continuous improvement of market demand, bottled liquid filling machine is moving towards intelligent, modular and environmental protection direction:

1. Intelligent development: equipped with artificial intelligence technology and sensor equipment, to achieve self-diagnosis, self-adjustment, thereby reducing the equipment failure rate and improve production efficiency.

2. Modular design: more and more filling machines with modular design, users can freely choose the number of filling heads, filling mode, etc., according to demand, to meet the needs of different production scale.

3. Green: energy-saving motors, water-saving cleaning systems, biodegradable materials for packaging adaptation has become the new focus of the equipment design, to help companies achieve the goal of sustainable development.

Bottle liquid filling machine is an important equipment in the automated production line, its high efficiency and accuracy significantly improve production efficiency and product quality. In the face of increasingly complex market demand, bottle liquid filling machine manufacturers need to continue to innovate and introduce more intelligent, environmentally friendly products to adapt to the new trends in the development of various industries. For enterprises, choose a suitable filling equipment, not only to meet the production needs, but also to lay a solid foundation for the long-term development of enterprises.