Release Date:2024-12-04 16:11:15 Popularity:

With the rapid development of industrial automation technology, automatic liquid quantitative filling machine has become one of the indispensable equipment in the production line of liquid products. It is widely used in food, beverage, chemical, pharmaceutical, daily chemical and other industries, with its high efficiency, precision, intelligent features, for the enterprise's production efficiency and product quality to provide a strong guarantee.

First, the working principle of automatic liquid quantitative filling machine

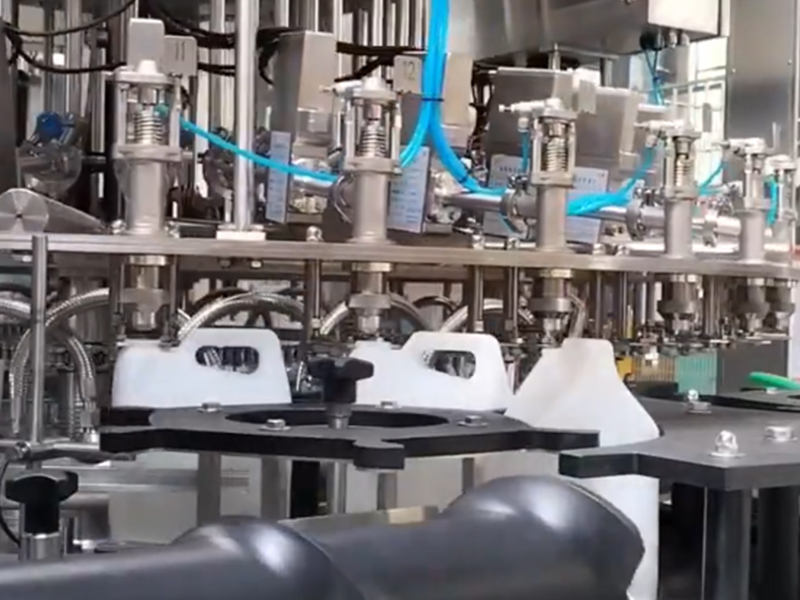

The automatic liquid quantitative filling machine takes the advanced control system as the core, detects the flow rate of liquid and the position of bottles through intelligent sensors, and combines the servo motor to control the filling speed and capacity. The equipment mainly consists of conveying system, quantitative control system, filling head and automatic sealing equipment. During the production process, the bottles are sent into the filling area by the conveyor belt in sequence, the liquid is injected into the bottles through the filling head, and the system carries out accurate quantitative filling according to the set parameters, so as to ensure the consistency of each bottle of product.

Second, the advantages of automatic liquid quantitative filling machine

1. Efficient production: automatic liquid quantitative filling machine set filling, measuring, capping and other functions in one, greatly improving production efficiency. Its continuous operation avoids the pause phenomenon in manual participation, especially suitable for mass production.

2. Accurate filling: through advanced flow meter or weight sensor, the automatic liquid quantitative filling machine can realize accurate control of filling quantity, and the error is usually controlled within ±1%. This not only reduces the waste of raw materials, but also ensures that the products meet the quality standards.

3. Multi-functional adaptability: this equipment is highly adaptable and can fill liquids of different viscosities, from water, oils to viscous sauces can be coped with. At the same time, the equipment can adjust the filling speed and capacity according to the demand, to meet the diversified production needs.

4. Intelligent operation: Equipped with a touch screen, users can intuitively set parameters and check the status of the equipment. Part of the equipment also supports remote monitoring and diagnosis, greatly reducing the difficulty of maintenance.

5. Clean and hygienic: in food, medicine and other fields, the cleanliness of the equipment is crucial. Automatic liquid quantitative filling machine is usually made of stainless steel, in line with GMP and other health standards, easy to clean and has good corrosion resistance.

Applicable industries and application cases

Automatic liquid quantitative filling machine is widely used in the following industries:

-Food industry: bottling production line for drinking water, fruit juice, milk and other liquid products.

-Pharmaceutical industry: precise filling of potion, injection, disinfectant and other highly demanding products.

-Chemical industry: packaging of industrial liquids such as lubricants, detergents, emulsifiers and so on.

-Daily chemical industry: filling of liquid daily chemicals such as shampoo, shower gel, hand soap.

For example, in a large fruit juice beverage enterprises, the use of automatic liquid quantitative filling machine, the hourly production capacity from the original 2,000 bottles to 6,000 bottles, the production cost is reduced by 30%, the product error rate is reduced to one thousandth, and has achieved significant economic benefits.

Fourth, the purchase of automatic liquid quantitative filling machine considerations

1. Capacity requirements: according to the specific requirements of the production line to choose the appropriate filling speed equipment to avoid waste of resources or equipment overload.

2. Liquid characteristics: to determine whether the filling machine is able to adapt to the viscosity, temperature and chemical properties of the required liquid, to ensure the smoothness of product filling.

3. After-sales service: choose the manufacturer that provides good technical support and after-sales service to ensure that equipment failure can be resolved in a timely manner.

4. Budget range: according to the enterprise's investment budget, comprehensively consider the cost-effectiveness of the equipment and long-term use of costs.

With the popularity of Industry 4.0, automatic liquid quantitative filling machines are developing towards intelligence and greening. For example, future equipment may incorporate artificial intelligence algorithms to further improve accuracy and productivity, while reducing energy consumption through energy-saving designs.

Fully automatic liquid quantitative filling machine is an important part of modern production line, representing the advanced level of industrial automation. Its high efficiency, precision and intelligent features not only promote the production upgrade of various industries, but also bring significant economic benefits and market competitiveness for enterprises. In the future, with the continuous innovation of technology, this type of equipment will open up a broader development space for the production and manufacturing industries.