Release Date:2024-12-04 16:02:02 Popularity:

Automated assembly line is an indispensable core component in modern manufacturing industry. It realizes efficient production from raw material processing to finished product assembly through a series of automated equipment and the application of intelligent technology. This efficient, precise and sustainable production method not only improves the production efficiency, but also reduces the labor cost, which wins the first opportunity for enterprises in the fierce market competition.

First, the definition and composition of automated assembly line

Automated assembly production line is to connect the various production aspects of the product by means of an assembly line, and to utilize automation technologies such as robots, sensors, and control systems for operation and management. It usually includes the following key parts:

1. Raw material transportation system: used to transfer raw materials or semi-finished products to the starting point of the production line.

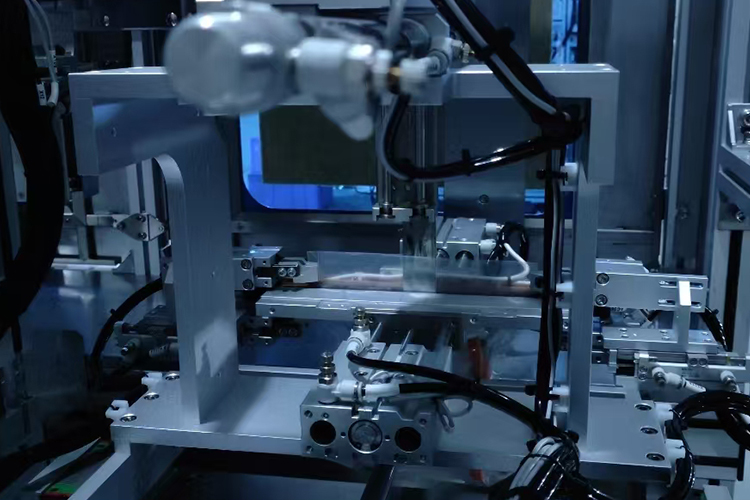

2. Processing equipment: according to the process requirements, the raw materials are cut, welded, painted and other processes.

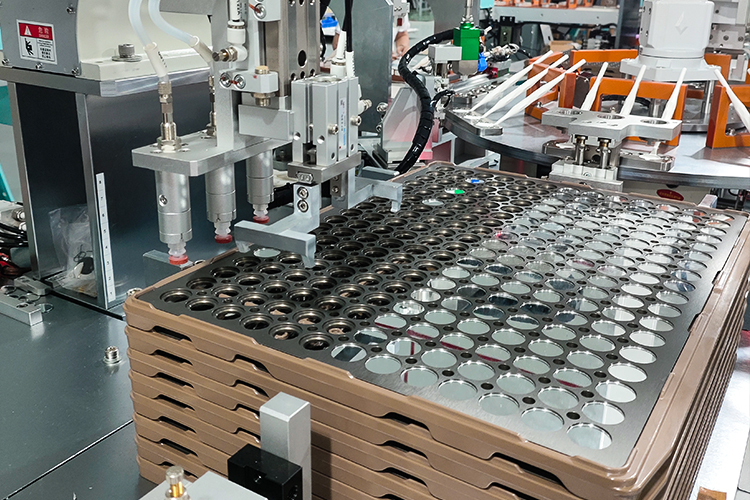

3.Assembly unit: assembling parts into finished products by using robots or automated tools.

4.Quality Inspection System: Ensure the product quality meets the standard by sensor or visual inspection equipment.

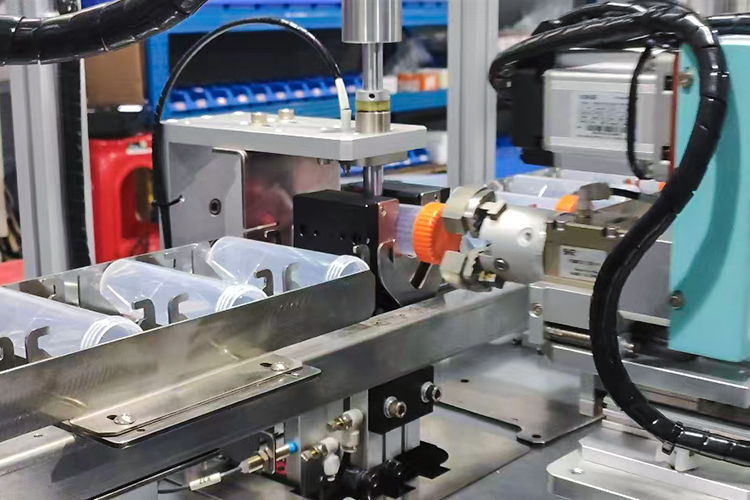

5. Finished product packaging and conveying system: Packaging and conveying the finished products to the designated place.

Second, the advantages of automated assembly line

1. Enhance production efficiency: the automated production line can operate continuously for a long time without the limitation of manual fatigue, which greatly improves the production efficiency. At the same time, the equipment is operated accurately, and can complete high-intensity, high-complexity production tasks in a short period of time.

2. Reduce labor costs: As many repetitive labors are completed by machines, enterprises need less manpower, thus reducing labor costs. Especially in the context of rising labor costs year by year, automated production lines have become an important means of cost control for enterprises.

3. Improve product quality: automated equipment has a high degree of consistency and stability, which can effectively avoid errors and deviations that may occur in manual operation, thus significantly improving product quality.

4. Enhance the flexibility and adaptability: modern automated assembly line through the modular design, can quickly adapt to changes in product categories and changes in market demand. Only need to adjust the program or part of the equipment, you can realize the production of different products.

Third, a wide range of application areas

Automated assembly line is widely used in many industries, including but not limited to the following areas:

1. Electronic manufacturing: the production process of smart phones, computers, household appliances, a large number of automated production lines are used to complete the assembly of precision parts.

2. Automotive industry: the production of engines, transmissions and other core components of the production process, can not be separated from the efficient support of automated assembly equipment.

3. Food processing: automated production lines can ensure food safety and hygiene, while improving the efficiency of packaging and filling.

4. Pharmaceutical industry: the filling, packaging and testing of drugs, automation technology plays an important role.

Fourth, the future development trend

With the continuous progress of science and technology, the functions of automated assembly line will be more diversified and the degree of intelligence will be further enhanced. The following trends are worthy of attention:

1. Integration with Internet of Things technology: in the future, automated production lines will pay more attention to the interconnection between equipment, realizing real-time monitoring and data analysis of the whole process, providing strong support for enterprise decision-making.

2. In-depth application of artificial intelligence: through the introduction of artificial intelligence technology, automated production lines will have the ability to self-learning and optimization, thus further improving efficiency and accuracy.

3. The promotion of green manufacturing concept: environmental protection requirements have prompted enterprises to seek low energy consumption and low emission production methods. Automated production line will play a key role in energy saving and emission reduction.

Automated assembly line is an important symbol of industrial modernization, its promotion and application not only changed the traditional manufacturing production mode, but also injected a strong impetus for the rapid development of the global economy. With the continuous progress of technology, automated assembly line will create greater value in more fields and lead the future development direction of manufacturing industry.