Release Date:2024-11-04 15:50:16 Popularity:

Automatic assembly equipment plays an indispensable role in modern industrial production, and is an important tool for realizing high-efficiency and low-cost production. With the diversification and refinement of market demand, automatic assembly equipment has been widely used in various manufacturing fields such as electronic products, automotive parts, medical devices and household appliances by virtue of its high efficiency, precision and repeatability. In this paper, the definition, composition, application advantages and future development direction of automatic assembly equipment will be discussed in depth.

First, the definition and composition of automatic assembly equipment

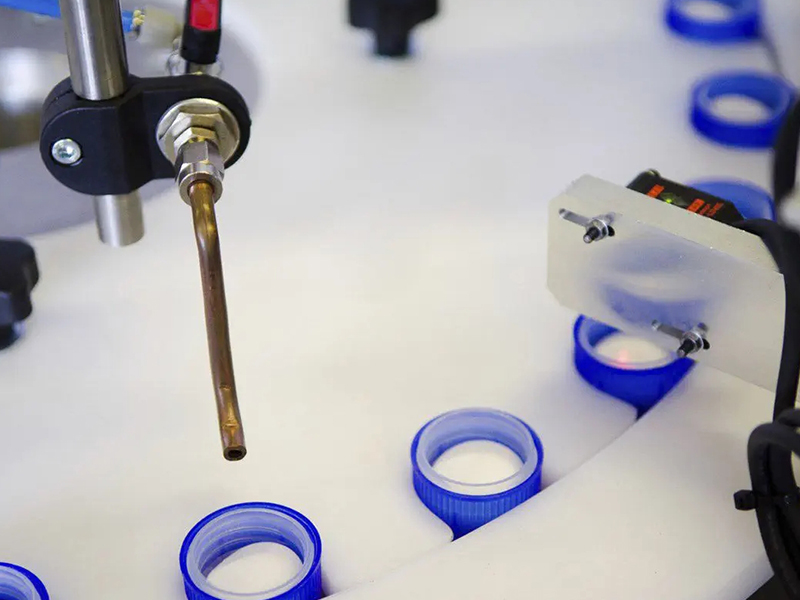

Automatic assembly equipment is a class of machinery and equipment systems that can complete the automated assembly of products. It is based on programming control, precision mechanism and a variety of sensors to realize the automated handling, docking, assembly and testing of products to ensure the uniformity and reliability of the assembly quality. Its components include the following core components:

1. Robot arm and transmission system: responsible for picking and placing, handling and accurate positioning of various parts of the product.

2. Control system: usually controlled by PLC (Programmable Logic Controller) or industrial computer to ensure the accuracy and flexibility of equipment operation.

3. Sensing system: including photoelectric sensors, pressure sensors, etc., used to detect and calibrate the position, to ensure the precise execution of each step of assembly action.

4. Positioning system: automatically aligns and fixes the assembly points of the assembled parts to ensure that each part is in the right position in the assembly process.

Second, the application advantages of automatic assembly equipment

Automatic assembly equipment has high productivity, flexibility and accuracy, which makes it show many unique advantages in modern production line:

1. Improve productivity: automatic assembly equipment can carry out production operations without interruption, free from artificial fatigue and efficiency fluctuations. This makes the production line can be completed in the same time more product assembly work.

2. Reduce labor costs: automated production reduces the need for manpower, especially in some repetitive, boring or dangerous assembly processes, the machine can replace the manual labor, to achieve efficient production and at the same time protect the safety of workers.

3. Enhance product consistency and quality: automatic assembly equipment based on precise control and standardized operation, to ensure that the assembly quality of each product is consistent, reduce the deviation caused by human factors, effectively improve the overall quality and reliability of the product.

4. Improve production flexibility: modern automatic assembly equipment usually has a modular design, by replacing different parts and software programs can be adapted to the assembly needs of different products, to facilitate the manufacturing enterprises to respond quickly to changes in market demand.

5. Optimize the utilization of resources: through automation control, you can more reasonably plan the operation of the production line to avoid waste, improve energy efficiency, and effectively control production costs.

Third, the typical application areas of automatic assembly equipment

Automatic assembly equipment is applicable to many industries, from the electronics industry to heavy industry, all rely on the efficiency and stability of automated assembly technology:

1. Electronic products: smart phones, tablet PCs and computers and other precision electronic products require high assembly accuracy, automatic assembly equipment can ensure the accurate docking of small parts to improve the product qualification rate.

2. Automobile manufacturing: automobile parts assembly involves a large number of complex assembly work, such as engine, transmission and other core components assembly. Automatic equipment can greatly improve the accuracy and efficiency of assembly.

3. Medical equipment: strict requirements on product cleanliness and safety, automatic assembly equipment can realize safe and pollution-free assembly process in dust-free workshop.

4. Household appliances: the assembly needs of the household appliance industry are diverse, automatic assembly equipment can help enterprises realize the rapid assembly of different types of household appliances and enhance the competitiveness of enterprises.

Fourth, the future development trend of automatic assembly equipment

With the deep development of intelligent manufacturing and industry 4.0, automatic assembly equipment will develop in the direction of more intelligent, flexible and green in the future.

1. Intelligent: the introduction of artificial intelligence and machine learning technology, so that the equipment has the ability of self-adaptation and self-diagnosis. For example, it can recognize and adjust unqualified parts in the assembly process to ensure product quality.

2. Flexibility: the future of automatic assembly equipment will be more flexible to adapt to the small batch, multi-species production needs. Through modular design and intelligent control system, enterprises can quickly adjust the production line to adapt to the assembly of different products.

3. Green: under the general trend of energy saving and emission reduction, automatic assembly equipment will use more environmentally friendly materials and processes to reduce energy consumption and reduce the impact on the environment.

The emergence and development of automatic assembly equipment has promoted the revolution of industrial production, which not only improves the production efficiency and reduces the cost, but also promotes the intelligence and refinement of production. In the future, with the continuous progress of science and technology, automatic assembly equipment will be applied in more fields, bringing far-reaching impact on the production methods of various industries.