Release Date:2024-08-16 11:47:00 Popularity:

In today's Industrial 4.0 era, automated assembly lines have become an indispensable production tool in major manufacturing industries. As the core promoter in this field, automated assembly line manufacturers play an extremely important role. They not only provide efficient production equipment for various enterprises, but also promote technological innovation and productivity improvement in the entire manufacturing industry. This article will explore the role, technical advantages, market demand and future development trends of automated assembly line manufacturers.

1. The importance of automated assembly line manufacturers

Automated assembly line manufacturers are the main suppliers of manufacturing production equipment, and their products and services directly affect the production efficiency and market competitiveness of enterprises. Automated assembly lines can connect various links in the production process to achieve continuous, stable and efficient production operations, thereby greatly improving production efficiency, reducing errors in human operations, and reducing production costs.

These manufacturers usually have strong technical R&D capabilities and rich industry experience, and can provide customized automation solutions according to the specific needs of customers. These solutions not only cover the design, manufacture and installation of production lines, but also include subsequent maintenance and upgrade services. Through close cooperation with enterprises, automated assembly line manufacturers help enterprises realize the transformation from traditional production mode to modern and intelligent production mode.

2. Technical advantages of automated assembly line manufacturers

1. Customized design: Automated assembly line manufacturers usually have a high degree of customized design capabilities. They can design the most suitable assembly line solutions according to the specific production needs and product characteristics of customers. This tailor-made service can ensure that the assembly line is highly consistent with the company's production process, thereby maximizing production efficiency.

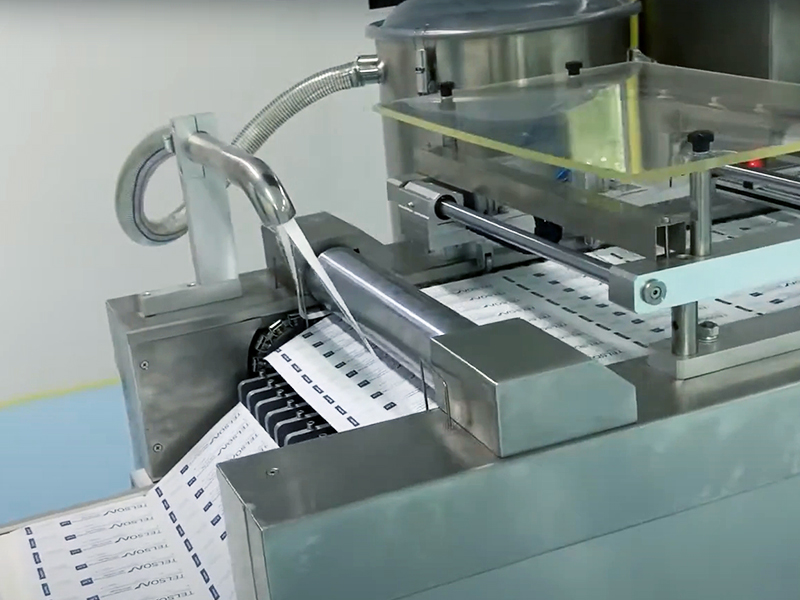

2. Advanced automation technology: Automated assembly line manufacturers usually use the latest automation technology and equipment in the research and development and manufacturing of production equipment. For example, robotics, the Internet of Things (IoT), artificial intelligence (AI), etc. have been widely used in modern automated assembly lines. The application of these technologies not only improves production efficiency, but also greatly enhances the intelligence and flexibility of the production process.

3. Stable and reliable product quality: Since automated assembly lines need to run stably for a long time in production, the stability of product quality is particularly important. Excellent automated assembly line manufacturers usually use high-quality materials and advanced manufacturing processes in the equipment manufacturing process to ensure the durability and reliability of the equipment, thereby reducing equipment failure rates and reducing maintenance costs.

4. Strong technical support and service: Automated assembly line manufacturers usually provide a full range of technical support and after-sales service, including installation and commissioning, operation training, equipment maintenance and technical upgrades. These services can help enterprises solve problems in time during use and ensure the smooth operation of the production line.

3. Market demand and application areas

With the development of industrial automation and intelligence, the market demand for automated assembly lines continues to increase. Automated assembly line manufacturers are also constantly expanding the application areas of their products. The following are several major market demands and application areas:

1. Automobile manufacturing: The automobile manufacturing industry is one of the important application areas of automated assembly lines. Automated assembly lines can effectively cope with the complex processes and high-precision requirements in the automobile production process, greatly improving production efficiency and product quality.

2. Electronic product manufacturing: In the field of electronic product manufacturing, the equipment provided by automated assembly line manufacturers can accurately complete the assembly of high-density electronic components to ensure the precision and consistency of products. This is especially important for the rapidly changing electronics market.

3. Food and beverage: The food and beverage industry has extremely high requirements for the hygiene standards of the production process. Automated assembly lines can achieve a fully enclosed and pollution-free production environment to ensure food safety. At the same time, the introduction of automated equipment has also greatly improved production efficiency and output.

4. Medicine and Chemical Industry: The pharmaceutical and chemical industries have high requirements for the accuracy and safety of the production process. Automated assembly lines can ensure that in a high-risk and high-precision production environment, the risks brought by human operation are reduced, and the quality and safety of products are guaranteed.

4. Future Development Trends

With the continuous advancement of science and technology, the development of automated assembly line manufacturers also presents the following trends:

1. Intelligence: In the future, automated assembly lines will be more intelligent. By introducing artificial intelligence and big data analysis technology, production lines can achieve self-monitoring and self-adjustment, and improve production flexibility and efficiency.

2. Green and environmental protection: With the enhancement of environmental awareness, automated assembly line manufacturers will pay more attention to the energy-saving design and environmental protection performance of equipment. Low-energy consumption and low-emission automated assembly lines will become an important direction for future development.

3. Flexible production: In the face of rapid changes in market demand, flexible production will become one of the trends in the development of automated assembly lines. Flexible production lines can quickly respond to the production needs of different products and reduce the time and cost of changing production lines.

4. Global expansion: With the transformation and upgrading of the global manufacturing industry, automated assembly line manufacturers will accelerate the layout of the global market, further expand the international market, and meet the needs of global companies for automated production equipment.

As the core promoter of modern manufacturing, automated assembly line manufacturers provide efficient and stable production solutions for all walks of life through continuous innovation and technological upgrading. With the advent of the Industrial 4.0 era, the application of automated assembly lines will be more extensive, and manufacturers will also usher in greater development opportunities. In the future, automated assembly line manufacturers will continue to play an important role in promoting the process of industrial automation and contribute to the intelligent transformation of the global manufacturing industry.