Release Date:2024-07-18 15:50:57 Popularity:

With the continuous advancement of agricultural modernization, liquid pesticides play a vital role in crop protection. In order to improve pesticide production efficiency and ensure product quality, liquid pesticide filling machines came into being. This advanced equipment can not only complete the filling of pesticides efficiently and accurately, but also shows significant advantages in ensuring safety, reducing waste and improving production consistency. Liquid pesticide filling machine has become an indispensable and important tool in modern agricultural production.

1. Definition and working principle of liquid pesticide filling machine

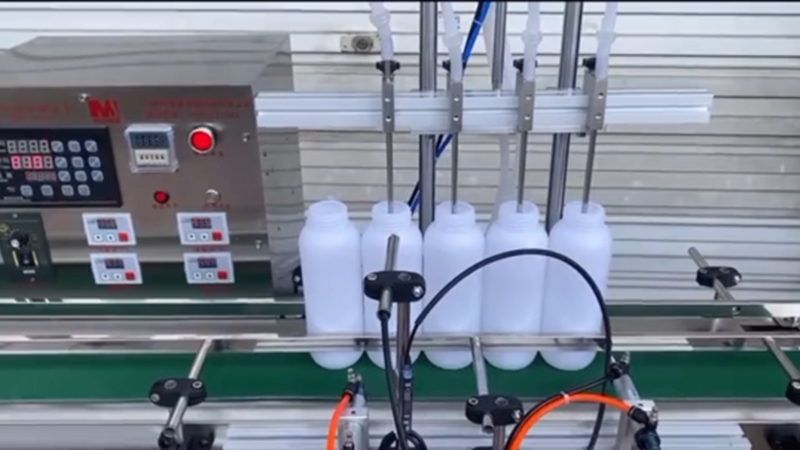

The liquid pesticide filling machine is a piece of equipment specially used for filling liquid pesticides. It uses automation technology to realize the full-process automation of liquid pesticides from feeding, metering, filling to sealing, ensuring that the filling amount of each bottle of pesticide is accurate and leak-free.

Its working principle mainly includes the following steps:

1. Feeding: Liquid pesticides enter the filling machine through the feeding system to ensure that the liquid can be continuously and stably supplied to the filling machine.

2. Measuring: The filling machine uses a precise measuring device to accurately measure the amount of liquid filled each time to ensure filling accuracy.

3. Filling: The liquid pesticide passes through the filling head and enters the pesticide bottle or other container. Filling heads are usually designed with anti-drip features to prevent liquid spillage and contamination.

4. Sealing: After filling is completed, the container is sealed by a sealing device to ensure that the pesticide does not leak during transportation and storage.

5. Detection and output: The filled products undergo quality inspection through the detection device, qualified products are transported to the output area, and unqualified products are rejected.

2. Advantages of liquid pesticide filling machine

1. Efficiency: The liquid pesticide filling machine can realize continuous and large-volume filling operations, greatly improving production efficiency. Compared with the traditional manual filling method, automated equipment is faster and can meet the huge demand of the pesticide market.

2. High precision: The liquid pesticide filling machine uses precise metering devices and control systems to ensure that the amount of each filling is accurate, reducing possible errors caused by human operation.

3. Safety: Liquid pesticides have certain dangers. Automated filling equipment reduces manual contact and reduces the safety risks of operators.

4. Reduce labor costs: Automated filling equipment reduces reliance on labor and reduces the company's labor costs. At the same time, the labor intensity of workers is reduced and the safety of the working environment is improved.

5. Reduce waste: High-precision filling and anti-drip design effectively reduce the waste of pesticides, reduce production costs, and reduce environmental pollution.

3. Application fields of liquid pesticide filling machine

Liquid pesticide filling machines are widely used in agricultural production, especially in pesticide manufacturing companies and agricultural service companies.

1. Pesticide manufacturing enterprises: In pesticide manufacturing enterprises, liquid pesticide filling machines are used for filling various types of liquid pesticides, which improves production efficiency and product quality and meets market demand.

2. Agricultural service companies: Agricultural service companies use liquid pesticide filling machines to provide farmers with efficient and accurate pesticide filling services, improving the scientific and professional level of agricultural production.

4. Development Trend of Liquid Pesticide Filling Machine

With the advancement of science and technology and the advancement of agricultural modernization, liquid pesticide filling machines are developing in the direction of intelligence, environmental protection, and multi-function.

1. Intelligentization: In the future, liquid pesticide filling machines will make greater use of technologies such as the Internet of Things, big data, and artificial intelligence to achieve more intelligent production management and quality control. Through data analysis and machine learning, the equipment can automatically optimize the filling process and improve production efficiency and product quality.

2. Environmental protection: The enhancement of environmental awareness promotes the development of liquid pesticide filling machines towards green development. Use more environmentally friendly materials and energy-saving technologies to reduce the impact on the environment during the production process.

3. Multifunctionality: Liquid pesticide filling machines will have more functions, such as automatic cleaning, automatic material changing, automatic detection, etc., to meet the diverse needs of different products and markets.

5. Application cases of liquid pesticide filling machine

1. Large-scale pesticide production: After a large pesticide manufacturer introduced a liquid pesticide filling machine, the production efficiency increased by 30%, and the product qualification rate reached over 99%, which significantly improved the company's market competitiveness.

2. Small agricultural service company: A small agricultural service company provides customized filling services to surrounding farmers by using liquid pesticide filling machines. It not only improves service quality, but also reduces pesticide waste, and has won widespread praise from farmers.

To sum up, the liquid pesticide filling machine, as a key equipment in modern agricultural production, is promoting the modernization and automation of pesticide production and filling with its high efficiency, high precision, safety and other advantages. In the future, with the continuous innovation and application of technology, liquid pesticide filling machines will bring more opportunities and challenges to agricultural production, pushing agriculture into a new era that is more intelligent, efficient and green.