Release Date:2024-06-03 15:12:35 Popularity:

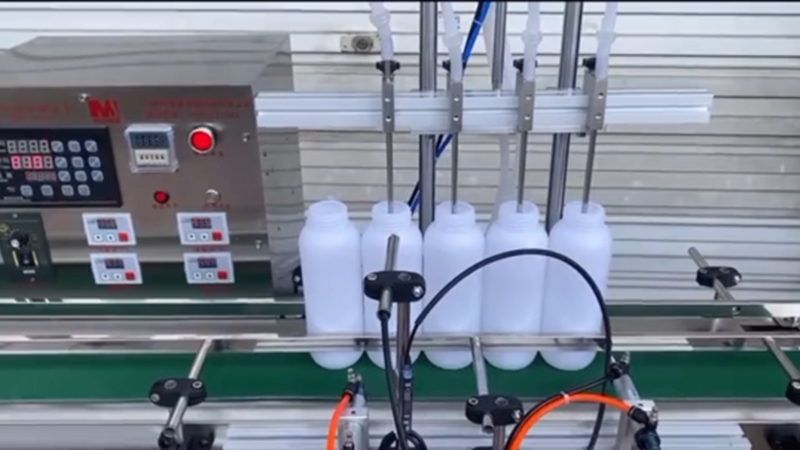

In modern industrial production, liquid filling is a key process, involving many industries such as food, medicine, cosmetics, chemicals and beverages. In order to meet the diverse market needs, multi-functional liquid filling machines have emerged. It not only has efficient and precise filling capabilities, but can also adapt to different types and viscosities of liquids, significantly improving production efficiency and product quality. This article will discuss in detail the characteristics, advantages and applications of multi-functional liquid filling machines in various industries.

Features of multifunctional liquid filling machine

1. High-precision filling: The multi-functional liquid filling machine uses advanced measurement technology, such as electronic weighing system, flow meter and servo control system, to ensure that the amount of liquid filled each time is accurate. High-precision filling not only ensures product consistency, but also reduces overuse and waste.

2. Adapt to a variety of liquids: This equipment can adapt to various liquids from low to high viscosity, including water, oil, lotion, juice, medicine, detergent, etc. Multifunctional liquid filling machines are equipped with a variety of filling valves and pump systems, such as peristaltic pumps, gear pumps and plunger pumps, to cope with the characteristics of different liquids.

3. Fully automated operation: Equipped with PLC control system and human-machine interface (HMI) to achieve fully automated operation. From material supply, filling, sealing to labeling and coding, the entire process does not require manual intervention, greatly improving production efficiency.

4. Easy to clean and maintain: The equipment adopts a modular design, and key components such as filling valves and pipelines can be quickly disassembled for easy cleaning and maintenance. Many multifunctional liquid filling machines are also equipped with automatic cleaning systems to meet production requirements of high hygiene standards.

5. Flexibility and adjustability: The equipment is designed to be flexible and can be quickly adjusted to accommodate containers of different capacities and shapes to meet various packaging needs. Through simple parameter settings and component replacement, the filling tasks of different products can be completed.

Advantages of multifunctional liquid filling machine

1. Improve production efficiency: Fully automated operation and high-speed filling capabilities significantly improve production efficiency, shorten the production cycle, meet the needs of large-scale production and fast delivery, and help companies maintain their leading position in fierce market competition.

2. Ensure product quality: High-precision measurement system and strict quality control process ensure the consistency and stability of each filling, reduce the defective rate, and improve the product qualification rate and brand reputation.

3. Reduce production costs: Automated equipment reduces reliance on manual operations and reduces labor costs. At the same time, efficient production processes and material utilization also reduce production costs and improve the economic benefits of the enterprise.

4. Improve safety and environmental protection: The multi-functional liquid filling machine is designed with operational safety and environmental protection requirements in full consideration. Through automated control and anti-drip design, the risks caused by human operation are reduced, complying with environmental protection standards, and reducing the effect on the environment.

5. Enhance market competitiveness: Efficient, precise and intelligent filling capabilities improve production flexibility and response speed, allowing companies to quickly adapt to market changes and customer needs, and improve market competitiveness and customer satisfaction.

Application fields of multi-functional liquid filling machine

1. Food and beverage industry: In the food and beverage industry, multi-functional liquid filling machines are widely used in the filling of juice, condiments, milk, drinking water, honey and other products. Efficient filling capacity and strict hygiene standards ensure food quality and safety.

2. Pharmaceutical industry: The pharmaceutical industry has extremely high requirements for the accuracy and cleanliness of filling equipment. Multifunctional liquid filling machines can meet the filling needs of pharmaceuticals, oral liquids, disinfectants and other products, ensuring the safety and effectiveness of medicines.

3. Cosmetics and personal care products: Cosmetics and personal care products such as lotions, perfumes, shampoos, conditioners, etc., usually have different viscosities and properties. The multifunctional liquid filling machine provides flexible filling and efficient production processes. , improving product consistency and packaging aesthetics.

4. Chemical industry: Many products in the chemical industry require precise measurement and safe packaging, such as lubricants, detergents, coatings, etc. Multifunctional liquid filling machines can provide efficient and accurate filling solutions to ensure product stability sex and safety.

5. Daily chemical industry: In the daily chemical industry, multi-functional liquid filling machines are used for filling various liquid cleaners, detergents, disinfectants and other products. Efficient filling process and precise metering ensure product quality and beautiful packaging.

As an important piece of equipment in the modern packaging industry, the multi-functional liquid filling machine has significantly improved production efficiency and product quality with its high efficiency, precision, multi-function and flexibility. In many fields such as food, medicine, cosmetics, chemicals and daily chemicals, multi-functional liquid filling machines have shown wide application prospects. With the continuous advancement of technology and changes in market demand, multi-functional liquid filling machines will continue to play an important role in promoting various industries to move towards efficient, intelligent and sustainable development. By introducing and optimizing multi-functional liquid filling machines, companies can not only improve their market competitiveness, but also better meet consumer needs and achieve sustainable development.