Machine Description: This machine is based on plastic, backlit sheet factory customer requirements and developed, in the current market, some existing machines cut the water mouth using cold cut, b

Machine Description:

This machine is based on plastic, backlit sheet factory customer requirements and developed, in the current market, some existing machines cut the water mouth using cold cut, but the acrylic cold cut will crack, and to cut the flat not cracked have to carry out the hot cut, but also to prevent sticking to the knife, so we purposely after a long time of experimentation and research and development to make this and the robot with close cooperation with the automatic cut water mouth machine; machine for the vertical machine, with the Injection molding machine height and location of the robot, the machine opens to set the temperature of the product required to cut the spout, when the robot to take out the product into our cut spout machine positioning fixtures, fixtures sensing the product positioning, positioning on the move to cut the spout position, cut the spout mechanism down to start cutting the spout, cut the spout mechanism rises, the spout with the up, loaded with products fixtures back to the original position, cut the spout mechanism to the spout Into the spout basin, cut the spout machine automatic manipulator rotates 180 degrees to take out the finished product and then rotate back to the assembly line, fixtures waiting for the next incoming material; so that the cut out of the product is flat, will not be cracked, there is no handprints, high quality, fewer personnel, especially for the satisfaction of customers with high requirements of the conditions.

This machine can be dual-use, cold cut, hot cut, each product needs a jig, different products cutter needs to be adjusted, you can also cut other products of the water mouth, high versatility, affordable.

Technical parameters:

1. Vertical structure, PLC control, simple operation interface, language Chinese.

2. Adopt guide rail guide, smooth running, long service life.

3. Adopting independent buffer air circuit for positioning, ensuring smooth positioning;.

4. The surface of the machine is treated to make the machine beautiful and generous.

5. The machine cutter is cleaned regularly, which makes the machine clean and tidy.

6. The whole machine is equipped with safety protection devices.

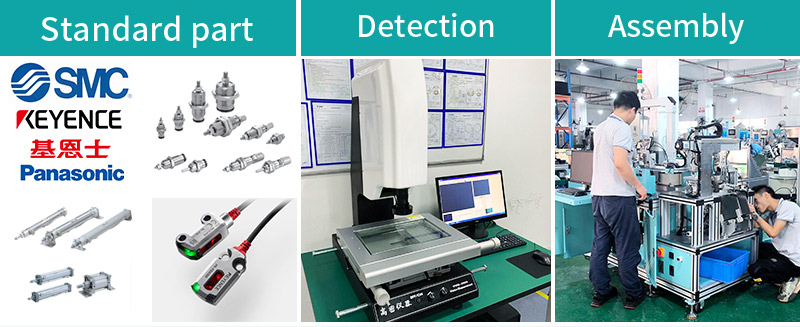

7. Cylinders, solenoid valves are made of Taiwan Yadek, and electrical appliances are made of Omron.

8. Voltage: 220V AC Air pressure: 0.4-0.6MPA.

9. Work efficiency with robot, size: L600 * W500 * H1500