Release Date:2025-07-03 11:04:07 Popularity:

In the context of the current medical device manufacturing industry moving towards intelligence and automation, how to improve production efficiency and ensure product consistency and safety has become an important manifestation of the core competitiveness of enterprises. The birth of the dental mirror automatic assembly machine is a precise response to this demand. It not only liberates a large amount of manpower and improves assembly efficiency, but also ensures that the dental mirror, a precision medical device, reaches higher quality standards during the production process.

1. Structure and assembly difficulties of dental mirrors

Dental mirrors, also known as oral mirrors, are indispensable tools for dentists in the diagnosis and treatment process. They are mainly composed of mirror handles, reflective lenses, mirror frames and connecting structures. Although the structure of dental mirrors is simple, they actually have extremely high requirements for manufacturing and assembly accuracy:

The mirror angle must be accurately matched to obtain the best reflective field of view;

The connection between the lens and the mirror handle must be firm to prevent it from falling off during clinical operation;

The material must be clean and pollution-free and meet medical and health standards;

The finished product must have batch consistency to facilitate sterilization and packaging.

The traditional manual assembly method is not only inefficient, but also prone to quality problems due to human errors in lens installation and frame locking. The automatic assembly machine for dental mirrors has greatly solved these pain points through mechanization and standardization.

2. Functional characteristics of automatic assembly machine for dental mirrors

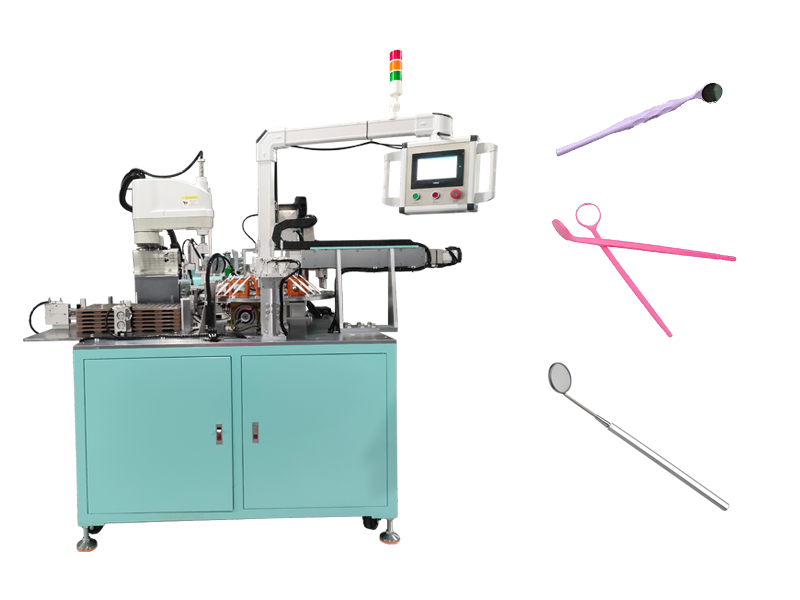

Automatic assembly machine for dental mirrors is an intelligent production equipment that integrates automatic feeding, lens alignment, plug-in locking, quality inspection, automatic unloading and other functions. Its main features include:

High-speed automated production: dozens to hundreds of dental mirrors can be assembled per minute to meet the needs of large-scale production.

High-precision visual positioning system: With the help of industrial cameras to identify the position of the lens and the mirror handle, accurate docking and plug-in can be achieved, effectively reducing the problems of offset and looseness.

Multi-station synchronous linkage design: Each assembly module operates in coordination, and the lens assembly, pressing, tightening and other actions are completed within seconds, greatly improving the production rhythm.

Intelligent detection and rejection system: Real-time monitoring of indicators such as whether the lens is damaged and whether the assembly is firm to ensure that each dental mirror meets the quality inspection standards.

Modular structure, easy maintenance: Each module can be replaced and upgraded independently to adapt to different specifications of dental mirror products, with extremely high flexible production capacity.

3, the technical composition of the equipment

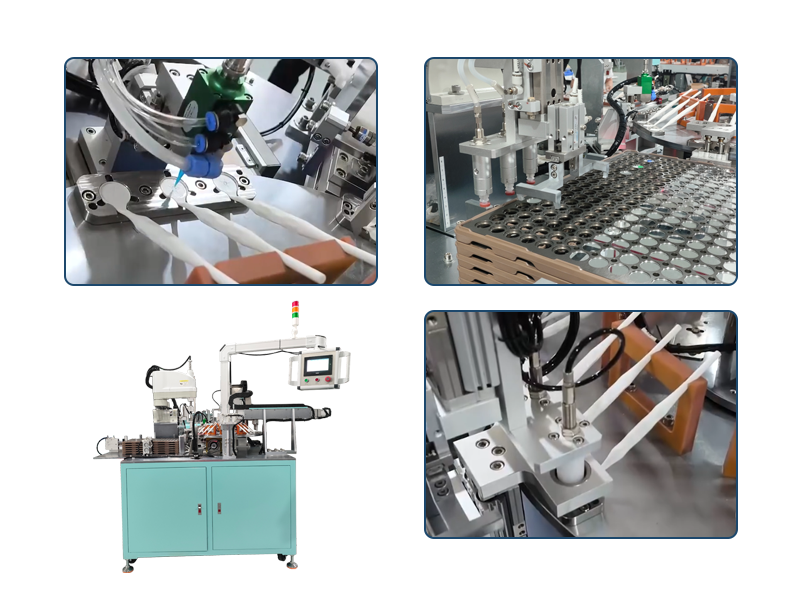

Automatic feeding system: automatic feeding through vibration plate, mechanical arm, feeding track, etc., to improve the supply efficiency;

Lens assembly unit: complete the precise placement and angle adjustment of the lens;

Mirror handle locking unit: automatically screw or press the mirror handle to ensure a firm connection;

CCD visual inspection system: detect the lens installation accuracy and assembly completion;

Automatic discharging system: qualified products are output and defective products are automatically removed.

The entire assembly process is highly integrated and can be seamlessly connected with subsequent laser marking and packaging equipment to build a complete automated production line.

The promotion and application of automatic assembly machines for dental mirrors is not only a microcosm of the improvement of the automation level of the medical device industry, but also an inevitable choice for enterprises to pursue high-quality, standardized and efficient manufacturing. It brings traditional manufacturing into a new era of intelligent production and provides safer and higher-quality basic tools for dental diagnosis and treatment.