Release Date:2025-02-18 16:11:30 Popularity:

With the continuous progress of industrialization, the demand for a variety of liquid products is also increasing, from daily beverages, mineral water to pharmaceutical and cosmetic industry liquid products, bottled liquid packaging market is huge and diverse. In order to improve production efficiency and packaging precision, bottle liquid filling machine as a modern production line of indispensable equipment, plays an important role. This article will focus on the working principle of the bottle filling machine, equipment features, applications and market prospects for detailed analysis.

First, the working principle of the bottle liquid filling machine

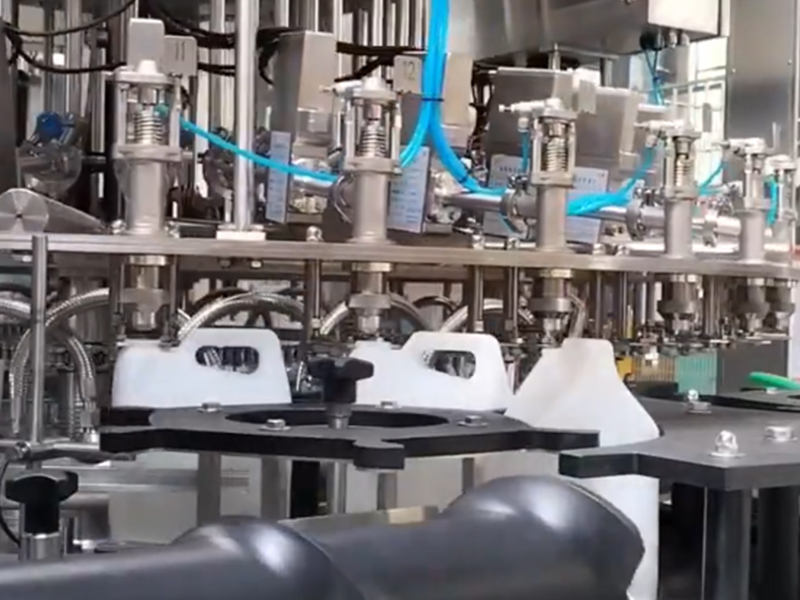

Bottle filling machine through the automation control system to complete the liquid quantitative filling, sealing, labeling and other processes. Its working principle can be generally divided into the following steps:

1. Bottle conveying and positioning: bottle filling machine first through the conveyor system will be sent to the empty bottle filling position. The conveyor belt system can realize the automatic transmission of bottles, and at the same time ensure that the bottles are stably and accurately aligned with the filling port through the mechanical arm or guide rail.

2. Liquid Filling: After the bottles are positioned, the filling system will be activated according to the set filling volume, and the liquid will enter the bottles through the filling head or nozzle. Bottle liquid filling machine can choose different filling methods according to the type of liquid, viscosity and bottle mouth size, such as gravity filling, pneumatic filling, quantitative filling and so on.

3. Bottle mouth sealing: after the liquid filling is completed, the bottle mouth will be closed by automatic sealing equipment. The sealing methods usually include heat sealing, pressure sealing or capping to ensure the sealing of the bottle to avoid liquid leakage or external pollution.

4. Labeling and Printing: After sealing, the bottle liquid filling machine can also be equipped with automatic labeling equipment to accurately affix the product label to the bottle. The label may include brand information, production date, batch number and other information, some equipment is also equipped with a coding machine, the production date and batch number printing.

5. Finished product output: after completing filling, sealing and labeling, the bottles are sent to the next process through the conveyor belt, such as quality testing, crating or warehousing.

Second, the bottle of liquid filling machine equipment features

1. High-precision quantitative filling: Bottle filling machine adopts advanced electronic measurement system or flow control system, which can ensure that the filling amount of each bottle is precise and accurate, and avoid product quality problems caused by improper filling.

2. Automatic operation: Bottle liquid filling machine realizes full automatic operation from bottle conveying, liquid filling to sealing and labeling. It greatly reduces the manual operation, improves the production efficiency and stability, and is especially suitable for mass production.

3. Diversified filling methods: according to the characteristics of different liquids, the bottle liquid filling machine provides a variety of filling methods. For example, pneumatic filling is suitable for gas and liquid mixtures, gravity filling is suitable for low-viscosity liquids, and quantitative filling is suitable for high-viscosity liquids.

4. Efficient sealing system: sealing is an important step in bottle filling, the bottle filling machine is equipped with a sealing system to ensure that the bottles are sealed tightly to avoid liquid leakage and maintain the freshness and safety of the product.

5. Easy to operate and maintain: modern bottle filling machines are usually equipped with a touch screen operator interface, the operator only needs to simply set the parameters to run the equipment. The equipment also has automatic fault diagnosis function, easy to maintain and manage.

Third, the application areas of the bottle liquid filling machine

1. Food and beverage industry: bottled liquid filling machine is widely used in the food and beverage industry. Beverages such as mineral water, fruit juice, carbonated beverages and other liquid filling need this equipment. The filling process is precise and efficient, and can meet the needs of mass production.

2. Pharmaceutical industry: In the pharmaceutical industry, bottle liquid filling machine is used for packaging of pharmaceutical liquids. Pharmaceutical liquids on the filling of precision and hygiene requirements are extremely high, the bottle filling machine can ensure that the liquid filling precision, and to ensure that the production process of aseptic conditions, to avoid product contamination.

3. Cosmetic industry: bottle liquid filling machine is also widely used in the cosmetic industry, especially in shampoo, skin cream, shower gel and other liquid products packaging. Cosmetic filling requires packaging precision and aesthetics, bottle filling machine can meet this demand.

4. Chemical industry: the chemical industry has a variety of liquid filling needs, such as lubricants, detergents, chemical solutions. Bottle filling machine can choose the appropriate filling method according to the nature of the liquid, to ensure the safety of liquids and accurate packaging.

Fourth, the market outlook for bottled liquid filling machine

With the growing global demand for liquid products, bottled liquid filling machine market prospects are very broad. Especially in the food and beverage, pharmaceutical and cosmetic industries, the market demand for efficient and accurate liquid packaging equipment will continue to rise. With the continuous progress of automation and intelligent technology, the bottle liquid filling machine is also developing in the direction of more efficient and intelligent.

1. Intelligent and automated development: with the advancement of industry 4.0, bottled liquid filling machine will be more intelligent. Through the Internet of Things technology, the equipment can real-time monitoring of production conditions, remote control and data analysis, optimize production efficiency.

2. Energy saving and environmental protection: with the gradual strengthening of environmental regulations, bottled liquid filling machine will make more efforts in energy saving and waste reduction. For example, the equipment will pay more attention to the efficient use of energy, reduce the waste of packaging materials, and promote green production.

3. Adapt to diversified needs: With the diversification of consumer demand, the bottle liquid filling machine will provide more flexible production capacity, able to quickly convert different bottle types, capacities, liquid types of production tasks, to adapt to the multi-species, small batch production needs.

The importance of bottle liquid filling machine in modern production can not be ignored, it improves production efficiency, ensure product quality, and adapt to the packaging needs of various types of liquid products. With the continuous progress of intelligent, energy-saving, environmentally friendly technology, bottled liquid filling machine applications will be more extensive, the market demand will continue to grow. In the future, the bottle liquid filling machine will continue to play an important role in a number of industries, to promote the efficient production and packaging of various types of liquid products.