Release Date:2024-08-22 11:28:01 Popularity:

Full-automatic linear filling machine is a kind of high-efficiency automated equipment widely used in liquid, paste, chemical, food, medicine and other industries. It is one of the indispensable equipments in the modern production line, which realizes high-precision and high-speed filling operation through the automatic control system in a linear filling mode. In this paper, we will discuss in detail the working principle of automatic linear filling machine, the main features, application areas and its advantages in the production process.

First, the working principle of automatic linear filling machine

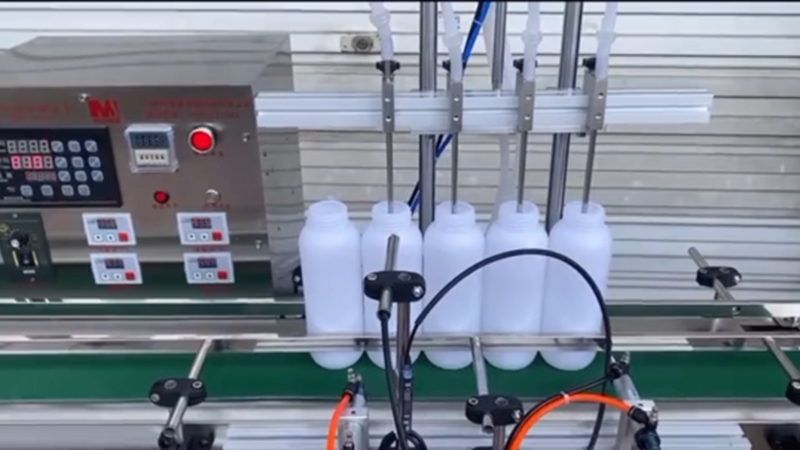

Automatic linear filling machine adopts linear conveying structure, filling head arranged in a straight line, through the conveyor belt to be filled containers are sent to the filling area in turn. During the filling process, the containers are positioned by sensors, and the filling head will automatically move down to the mouth of the container and start filling. When the filling is completed, the filling head moves up and the container is conveyed to the next station for sealing or other processing.

The core control system of the automatic linear filling machine is usually operated by PLC (Programmable Logic Controller) and touch screen human-machine interface. The operator can set the filling parameters through the touch screen, such as filling volume, speed, number of filling heads and so on. The equipment can automatically complete the filling, measuring, testing and other processes to ensure the accuracy and consistency of each bottle filling.

Second, the main features of automatic linear filling machine

1. High-precision filling: automatic linear filling machine is usually equipped with high-precision flow meter or load cell to ensure the accuracy of each bottle filling. This high-precision control system can effectively reduce product loss and improve product quality.

2. Wide range of application: the equipment is suitable for filling a variety of liquids and pastes, such as mineral water, beverages, cosmetics, pharmaceuticals, chemical products and so on. Its linear structure makes it very convenient to replace bottles of different specifications and filling materials, which greatly improves the adaptability of the production line.

3. High degree of automation: the automatic linear filling machine integrates the functions of automatic bottle supply, automatic filling, automatic inspection and automatic sealing. The equipment can automatically identify whether the container is in place, whether the filling head is working properly and so on, which greatly reduces the manual intervention and improves the production efficiency.

4. Easy operation: the equipment adopts PLC control and touch screen human-machine interface, the operator only needs to simply set the parameters to start the equipment and automatically complete the filling work. The equipment is also equipped with intelligent fault diagnosis system, once the problem occurs, the system will automatically alarm and display fault information, convenient for maintenance.

5. Easy to clean and maintain: the design of automatic linear filling machine usually takes into account the food and pharmaceutical industry's high demand for hygiene, the equipment has a simple structure, easy to dismantle and clean, and can quickly replace the products on the production line to reduce downtime.

Third, the application areas of automatic linear filling machine

Automatic linear filling machine is widely used in the following industries due to its high precision and high efficiency:

1. Food and beverage industry: In the food and beverage industry, especially in the production process of mineral water, fruit juice, dairy products and other liquid products, filling accuracy and hygiene standards are key. Full-automatic linear filling machine can ensure that the filling amount of each bottle of product is accurate, to avoid too much or too little, in line with industry standards.

2. Pharmaceutical industry: the pharmaceutical industry requires high filling accuracy, especially in the production of medicinal liquid, disinfectant and other products, automatic linear filling machine can meet the requirements of high precision, high cleanliness, to ensure product quality and safety.

3. Cosmetic industry: cosmetic industry lotions, shampoos, skin care products and other products usually require fine filling operations. Automatic linear filling machine can effectively reduce product waste and ensure the consistency of each bottle.

4. Chemical industry: chemical products such as lubricants, detergents, etc., usually has a certain viscosity and chemical activity. Automatic linear filling machine is usually made of corrosion-resistant materials, suitable for a variety of chemical products filling needs.

Fourth, the advantages of automatic linear filling machine

1. Improve production efficiency: the traditional manual filling method is inefficient and prone to error, while the automatic linear filling machine can complete a large number of products in a short period of time filling, greatly improving production efficiency.

2. Reduce production costs: Through the application of automatic production line, it reduces manual operation and lowers labor costs. At the same time, high-precision filling can reduce product loss, further reducing production costs.

3. Ensure product quality: automatic linear filling machine can ensure that the filling volume of each bottle of product is accurate and consistent, avoiding the errors brought about by manual operation, and improving the qualification rate of the product.

4. Adapt to a variety of production needs: the equipment's versatility and flexibility so that it can adapt to the production needs of different products, thus providing more production options and market competitiveness.

As an important part of the modern automated production line, the automatic linear filling machine brings great advantages to the production of various industries with its high efficiency and accurate filling capacity. With the continuous development of automation technology, automatic linear filling machine will be used in more fields, and continue to promote the industry's technological progress and improve production efficiency. Enterprises in the choice of filling equipment, should be based on their own production needs and product characteristics, choose the right equipment, in order to achieve the double enhancement of production efficiency and product quality.