Release Date:2024-08-19 11:49:44 Popularity:

As the core equipment in the modern packaging industry, the automatic heat-sealing packaging machine is widely used in food, medicine, daily chemicals and other fields, providing an efficient and safe packaging solution. It seals the packaging material through heat sealing technology, thereby ensuring the quality and safety of the product. In this article, we will discuss in detail the working principle, technical advantages, application fields and impact of the automatic heat-sealing packaging machine on the packaging industry.

1. Working principle of automatic heat-sealing packaging machine

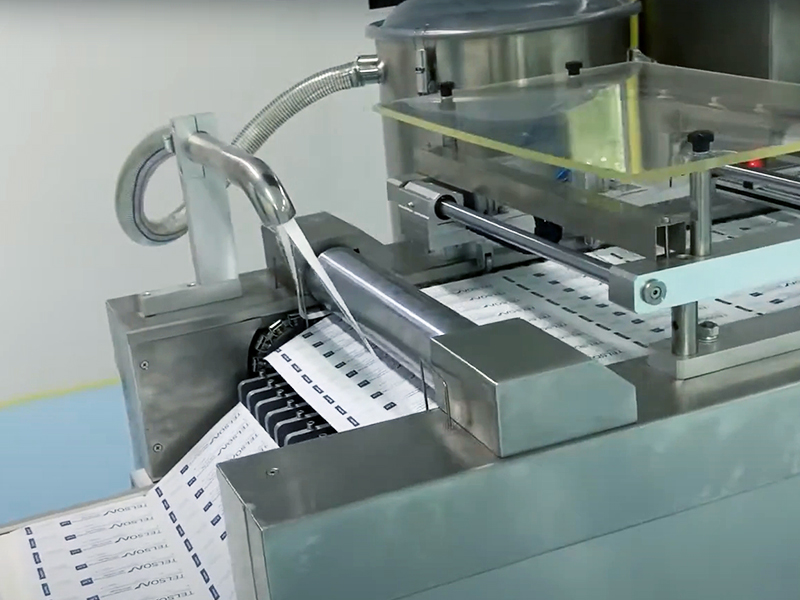

The core working principle of the automatic heat-sealing packaging machine is to apply heat to the packaging material through the heating element to soften and melt the surface layer of the packaging material, and then use pressure to tightly combine the edges of two or more packaging materials to form a seal. The whole process includes the following steps:

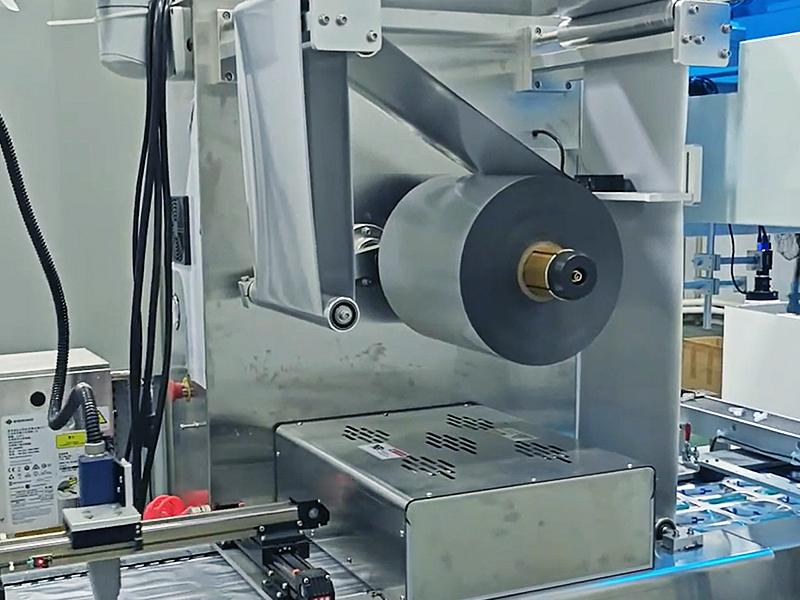

1. Material conveying: The packaging material enters the heat-sealing area through the conveying system. Common packaging materials include plastic film, aluminum foil, composite materials, etc., which can form a good sealing effect during the heat-sealing process.

2. Heat-sealing heating: The heating element applies heat to the packaging material in the heat-sealing area to make it reach the melting temperature. These heating elements can usually provide heat through electric heating, hot air or ultrasonic waves.

3. Pressurized sealing: When the packaging material is heated to a molten state, the machine will apply a certain amount of pressure to press the edges of the material together to form a firm seal.

4. Cooling and cutting: After the heat seal is completed, the material usually needs to be cooled to fix the sealing effect. Next, the automatic heat sealing packaging machine will cut the sealed package to form a single packaging unit.

5. Finished product output: The sealed and cut products are transported to the finished product output area, ready for subsequent packaging or transportation.

2. Technical advantages of automatic heat sealing packaging machine

1. Efficient production: The automatic heat sealing packaging machine can complete the packaging process continuously and quickly, greatly improving production efficiency. Automated operation reduces human intervention, making the entire packaging process smoother and suitable for mass production.

2. Excellent sealing effect: Heat sealing technology can ensure a firm bond between packaging materials, prevent air, moisture and contaminants from entering the interior of the package, thereby extending the shelf life of the product and ensuring product quality.

3. Wide material compatibility: The automatic heat sealing packaging machine is suitable for a variety of packaging materials, such as plastic film, aluminum foil, paper-based composite materials, etc. According to different packaging requirements, the machine can adjust the temperature and pressure parameters to adapt to the packaging requirements of different materials.

4. Cost saving: Since the automatic heat sealing packaging machine can pack efficiently, it reduces the waste of packaging materials and labor costs. In addition, the maintenance cost of the machine is relatively low, which further reduces the production cost.

5. Automation and intelligence: Modern automatic heat sealing packaging machines are usually equipped with advanced automatic control systems, which can perform precise temperature control, speed adjustment and quality inspection. These functions not only improve production efficiency, but also can timely detect and correct problems in production to ensure packaging quality.

3. Application fields of automatic heat sealing packaging machines

1. Food industry: The food industry is one of the most important application fields of automatic heat sealing packaging machines. Whether it is dried fruits, snacks, fast food products, or liquid beverages, automatic heat sealing packaging machines can effectively seal and package to ensure the freshness and safety of food.

2. Pharmaceutical industry: In the pharmaceutical industry, the packaging of medicines requires strict sealing and hygiene standards. Automatic heat sealing packaging machines can provide safe sealed packaging for medicines and medical devices, prevent contamination, and extend the shelf life of medicines.

3. Daily chemical industry: Daily chemical products, such as shampoo, shower gel, skin care products, etc., are usually sealed and packaged with automatic heat-sealing packaging machines. Heat-sealing packaging can prevent liquid leakage and ensure the product experience.

4. Industrial products: Automatic heat-sealing packaging machines are also widely used in the packaging of industrial products, such as hardware, electronic components, etc. Sealed packaging not only protects products from the external environment, but also facilitates the storage and transportation of products.

4. The impact of automatic heat-sealing packaging machines on the packaging industry

The wide application of automatic heat-sealing packaging machines has had a profound impact on the packaging industry:

1. Improve production efficiency: The efficient operation of automatic heat-sealing packaging machines has greatly improved the production capacity of packaging production lines, enabling companies to respond to market demand more quickly and shorten delivery cycles.

2. Improve packaging quality: Through precise temperature and pressure control, automatic heat-sealing packaging machines ensure the sealing effect of each package, thereby improving the overall packaging quality of the product.

3. Promote the development of packaging technology: The application of automatic heat-sealing packaging machines has promoted the development of packaging technology, especially in the innovation of packaging materials and sealing technology. With the continuous advancement of technology, the product quality and production efficiency of the packaging industry will be further improved.

4. Environmental protection and sustainability: Automatic heat-sealing packaging machines can optimize the use of packaging materials and reduce waste. At the same time, they encourage the use of degradable or recyclable packaging materials, which promotes the environmental protection and sustainable development of the packaging industry.

As a key equipment in the packaging industry, the automatic heat-sealing packaging machine provides high-quality packaging solutions for various products through its efficient working principle and excellent technical advantages. With the continuous growth of market demand, the automatic heat-sealing packaging machine will be used in more fields and continue to promote the advancement of packaging technology. In the future, with the further integration of intelligence and environmental protection concepts, the automatic heat-sealing packaging machine will ensure product quality and safety while promoting the packaging industry to develop in a more efficient and sustainable direction.