Release Date:2024-07-20 18:43:55 Popularity:

With the rapid development of the consumer goods market and the continuous improvement of people's requirements for product quality, the importance of packaging technology in industrial production has become increasingly prominent. As a key equipment in the modern packaging industry, the automatic packaging and sealing machine is widely used in food, medicine, cosmetics, daily necessities and other fields. It not only improves production efficiency, but also ensures the sealing and hygienic safety of the product, becoming an important tool for enterprises to enhance their competitiveness. This article will explore the definition, working principle, advantages and application of automatic packaging and sealing machines in various industries.

1. Definition and working principle of automatic packaging and sealing machine

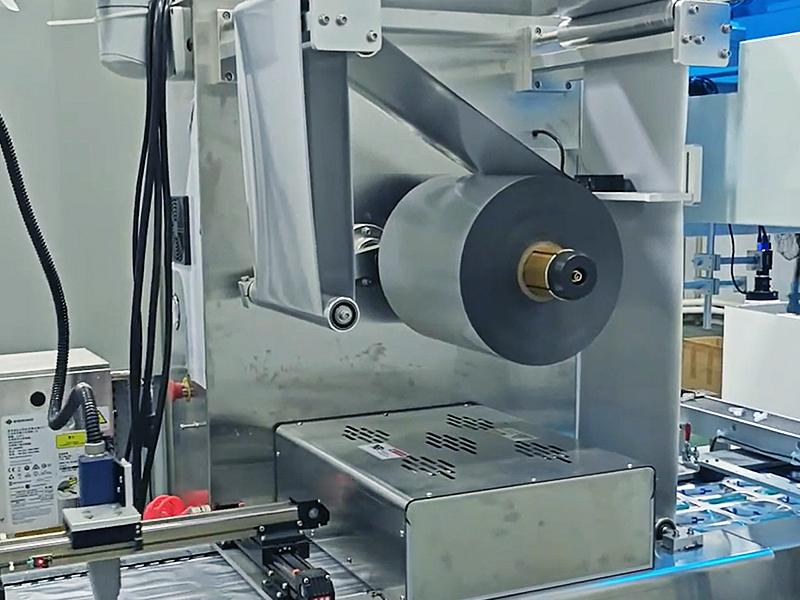

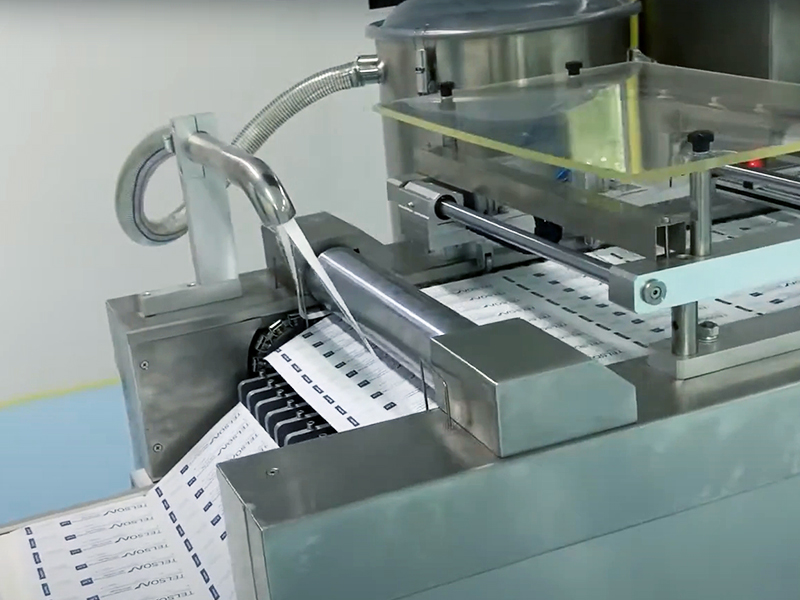

Automatic packaging and sealing machine is a device that automatically completes the product packaging and sealing process by mechanical means. It can put the product into a packaging bag or container, and seal the package by heating, pressing or other means to ensure the safety and stability of the product during storage and transportation.

Its working principle mainly includes the following steps:

1. Feeding: The product enters the packaging area through a conveyor belt or other feeding device.

2. Packaging: The automatic packaging machine puts the product into a pre-prepared packaging bag or container. This process can adopt different packaging forms according to the characteristics of different products, such as bagging, bottled, boxed, etc.

3. Sealing: The packaged products are sealed by the sealing machine. Sealing methods include heat sealing, pressing, bonding, etc. The specific choice depends on the packaging materials and product requirements.

4. Inspection and output: The sealed products are inspected by the inspection device for quality, qualified products are transported to the output area, and unqualified products are rejected.

II. Advantages of automatic packaging and sealing machines

1. Improve production efficiency: The automatic packaging and sealing machine can realize continuous and large-scale packaging and sealing operations, greatly improving production efficiency. Compared with manual operation, automated equipment is faster and has a shorter production cycle.

2. Ensure product quality: Through precise control systems and testing equipment, automatic packaging and sealing machines can ensure the consistent sealing quality of each product and reduce quality differences caused by manual operation.

3. Reduce labor costs: Automated equipment reduces dependence on labor and reduces the labor costs of enterprises. At the same time, it reduces the labor intensity of workers and improves the working environment.

4. Improve safety: The automated packaging and sealing process reduces manual intervention and reduces the risk of work-related injuries. The safety protection measures and emergency stop devices of the equipment ensure the safety of the production process.

5. Achieve hygienic packaging: Automatic packaging and sealing machines usually use easy-to-clean materials such as stainless steel, which meet the hygiene standards of the food and pharmaceutical industries and ensure the hygiene and safety of products.

III. Application fields of automatic packaging and sealing machines

Automatic packaging and sealing machines are widely used in various industries, especially in the fields of food, medicine, cosmetics and daily necessities.

1. Food industry: In the food industry, automatic packaging and sealing machines are used for packaging and sealing of various foods, such as snacks, seasonings, beverages, etc. Through automated equipment, the speed and quality of food packaging have been significantly improved to ensure the freshness and safety of food.

2. Pharmaceutical industry: Pharmaceutical products have extremely high requirements for packaging and sealing. Automatic packaging and sealing machines can meet the strict packaging requirements of products such as medicines and medical devices to ensure the effectiveness and safety of products.

3. Cosmetics industry: Cosmetics such as creams, lotions and other products are packaged efficiently and hygienically through automatic packaging and sealing machines to improve the market competitiveness of products.

4. Daily necessities industry: In the daily necessities industry, automatic packaging and sealing machines are widely used in the packaging of detergents, skin care products, cleaning products and other products, which improves production efficiency and product quality.

IV. Development trend of automatic packaging and sealing machines

With the continuous advancement of science and technology, automatic packaging and sealing machines are developing in the direction of intelligence, greening and multi-function.

1. Intelligence: In the future, automatic packaging and sealing machines will use more technologies such as the Internet of Things, big data, and artificial intelligence to achieve intelligent monitoring and management of the production process. Through data analysis and machine learning, the equipment can automatically optimize the packaging and sealing process to improve production efficiency and product quality.

2. Greening: The enhancement of environmental awareness promotes the greening of automatic packaging and sealing machines. Use more environmentally friendly materials and energy-saving technologies to reduce the impact on the environment during the production process and promote sustainable production.

3. Multi-function: Automatic packaging and sealing machines will have more functions, such as automatic cleaning, automatic material replacement, automatic detection, etc., to meet the diverse needs of different products and markets.

5. Implementation Cases of Automatic Packaging and Sealing Machines

1. A food manufacturing company: After a large food manufacturing company introduced automatic packaging and sealing machines, its production efficiency increased by 30%, and its product qualification rate reached more than 99%, significantly improving its market competitiveness.

2. A pharmaceutical company: A pharmaceutical company achieved efficient packaging and strict sealing of medicines by using automatic packaging and sealing machines, ensuring the safety and effectiveness of its products.

To sum up, as a key equipment in the modern packaging industry, the automatic packaging and sealing machine is promoting the packaging of various industries to be modernized, automated and intelligent with its advantages of high efficiency, high quality, safety and hygiene. In the future, with the continuous innovation of technology and the deepening of its application, the automatic packaging and sealing machine will bring more opportunities and challenges to the packaging industry, and promote the global packaging industry into a new era of more intelligent, efficient and sustainable development.