Release Date:2024-07-16 15:26:29 Popularity:

In the fierce competition in the global manufacturing industry, intelligent automated production lines are becoming an important means for enterprises to improve production efficiency, reduce costs and enhance competitiveness. Intelligent automated production lines realize the automation, digitization and intelligence of the production process by integrating modern information technology, automation control technology and intelligent manufacturing technology, thus bringing revolutionary changes to enterprises.

1. Definition and characteristics of intelligent automated production lines

Intelligent automated production lines refer to the comprehensive intelligentization of production equipment and production processes based on traditional automated production lines, combined with technologies such as the Internet of Things, big data, and artificial intelligence, through intelligent perception, intelligent control, and intelligent decision-making. It has the following salient features:

1. Efficiency: Intelligent automated production lines can achieve continuous and uninterrupted production, greatly improving production efficiency. By optimizing the production process, waste and waiting time during production are reduced.

2. Flexibility: Unlike traditional fixed production lines, intelligent automated production lines are highly flexible. It can quickly adjust production plans and production line configurations according to production needs, and adapt to multi-variety, small-batch production models.

3. Accuracy: The intelligent automated production line uses high-precision sensors and intelligent control systems to achieve precise control and monitoring of the production process, ensuring the consistency and stability of product quality.

4. Adaptability: Intelligent automated production lines can continuously optimize production parameters, automatically adjust production strategies, and improve production efficiency and product quality through data analysis and machine learning.

2. Core technology of intelligent automated production line

The realization of intelligent automated production lines requires the support of a variety of core technologies, including the Internet of Things, big data, artificial intelligence, robotics, cloud computing, etc.

1. Internet of Things (IoT): IoT technology realizes interconnection between equipment and equipment, equipment and systems by embedding sensors and communication modules in production equipment and production lines, and collects production data in real time to provide a basis for intelligent decision-making.

2. Big data: Big data technology provides data support for production optimization by storing, processing and analyzing massive data generated during the production process, mining the patterns and values behind the data.

3. Artificial intelligence (AI): Artificial intelligence technology analyzes and models production data through algorithms such as machine learning and deep learning to achieve intelligent optimization and predictive maintenance of the production process.

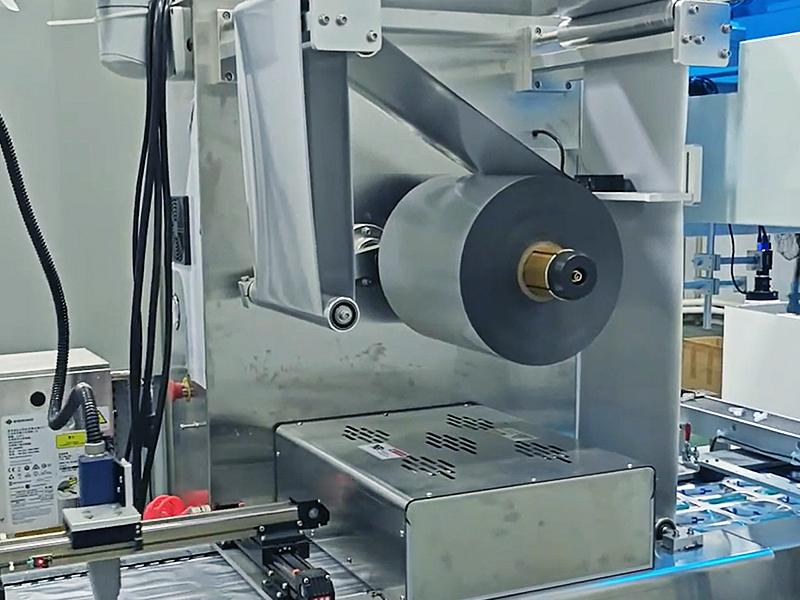

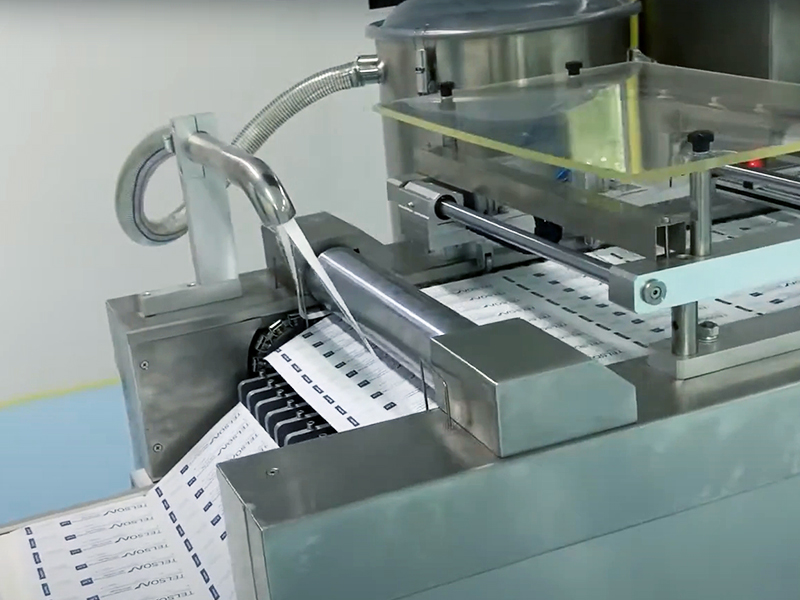

4. Robot technology: Modern industrial robots play an important role in intelligent automated production lines. They can complete a variety of tasks such as welding, assembly, and handling, improving production efficiency and precision.

5. Cloud computing: Cloud computing technology supports large-scale data processing and complex model calculations of intelligent automated production lines by providing powerful computing power and storage resources.

3. Application and prospects of intelligent automated production lines

Intelligent automated production lines are widely used in various industries. Taking the automobile manufacturing industry as an example, intelligent automated production lines can automate the entire process from parts production and assembly to vehicle inspection, improving production efficiency and product quality. In the electronics manufacturing industry, intelligent automated production lines can achieve high-precision assembly and testing of electronic components, reducing defective rates and production costs.

In addition, intelligent automated production lines also have broad application prospects in food processing, pharmaceutical manufacturing, home appliance production and other fields. With the continuous advancement of technology and the reduction of costs, intelligent automated production lines will be further popularized, promoting the transformation of the manufacturing industry to intelligence and digitalization.

4. Challenges of intelligent automated production lines

Although intelligent automated production lines have many advantages, they still face some challenges in their promotion and application. The first is technical challenges. Intelligent automated production lines involve the integration and application of multiple complex technologies, and technical difficulties need to be overcome. Secondly, there is the cost challenge. The construction and maintenance costs of intelligent automated production lines are high, which puts great financial pressure on small and medium-sized enterprises. In addition, the application of intelligent automated production lines also requires supporting management systems and talent support.

In summary, intelligent automated production lines, as the future development direction of the manufacturing industry, have broad application prospects and huge development potential. With the continuous advancement of technology and the continuous promotion of applications, intelligent automated production lines will become an important engine for promoting the high-quality development of the manufacturing industry.