Release Date:2024-09-11 11:55:12 Popularity:

With the rise of industry 4.0, automation technology in the manufacturing industry is increasingly elevated, automated assembly line manufacturers as the main promoter of this technology, plays an irreplaceable role. Automated assembly line not only significantly improves production efficiency and product quality, but also reduces labor costs, and reduces errors in human operation. By seamlessly connecting all aspects of the production process, the automated assembly line provides a more efficient and intelligent production solution for modern enterprises. In this article, we will discuss the role of automated assembly line manufacturers in modern industry, advantages and its future development trend.

First, the definition and application of automated assembly line

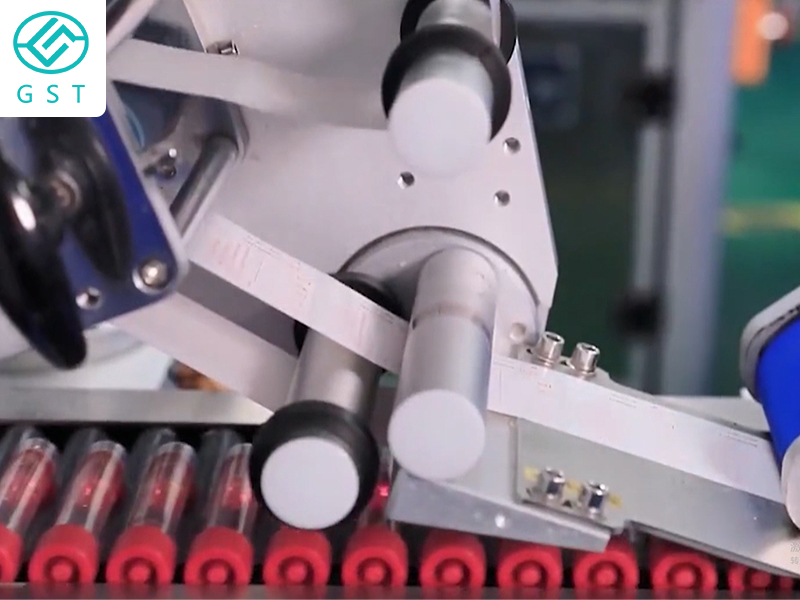

Automated assembly line refers to a series of mechanical equipment, transmission systems and intelligent control systems in manufacturing, to realize the fully automated operation of products from raw materials to finished products. The production process usually includes feeding, processing, assembling, testing, packaging and other aspects, each of which is completed by machinery and equipment, and the various processes are connected through the transmission system to form a continuous and stable production process.

Automated assembly line is widely used in various industries, such as automobile manufacturing, electronics production, food processing, pharmaceutical production, home appliance manufacturing and so on. According to different production needs, automated assembly line can be customized design, to adapt to different product types and production scale.

Second, the core competitiveness of automated assembly line manufacturers

1. Technological innovation and R & D capabilities: the design and production of automated assembly line requires strong technical support, automated assembly line manufacturers usually have a high level of R & D capabilities and technological innovation. The production needs of each industry are different, so manufacturers need to develop suitable automation solutions for different products and production processes. Technological innovation is not only reflected in the intelligent control of equipment and optimization of mechanical structure, but also in the flexibility and expandability of the production line.

For example, in the field of automobile manufacturing, assembly line manufacturers must develop automated assembly systems that can handle different models of vehicles, and these systems are capable of efficiently assembling a wide range of parts through simple programming adjustments. In addition, with the development of Internet of Things (IoT) technology, more and more manufacturers are integrating intelligent sensors, data acquisition and monitoring systems into their production lines to realize real-time monitoring and management of production data.

2. Customized production capacity: Another core competitiveness of automated assembly line manufacturers is their customized services. Different enterprises have different production processes, product specifications and plant layout, so the standardized assembly line equipment often can not fully meet their needs. Automated assembly line manufacturers through in-depth communication with customers to understand their specific production processes and needs, to provide customized assembly line design solutions. Customized production capacity allows manufacturers to provide customers with more accurate and efficient equipment to ensure that the production line to maximize the operating effect.

For example, in the food processing industry, different types of food have different requirements for the production line's hygiene standards, processing methods, packaging forms and so on. Manufacturers can design an automated assembly line that meets the standard according to the characteristics of the food to ensure the safety and hygiene of the production process.

3. Efficient after-sales service system: automated assembly line involves a variety of equipment, complex technology, so the degree of perfection of the after-sales service system directly affects the customer's production efficiency. Automated assembly line manufacturers usually provide a full range of after-sales service, including equipment installation and commissioning, operation training, regular maintenance and troubleshooting. Efficient after-sales service system can help customers quickly solve production problems encountered to ensure the normal operation of the assembly line.

Third, the advantages of automated assembly line

1. Improve production efficiency: automated assembly line can significantly improve production efficiency through a continuous, stable production process. Traditional manual operation requires a lot of time and labor, while automated equipment can run uninterruptedly, greatly reducing the production cycle.

2. Reduce production costs: through the automated assembly line, enterprises can reduce the dependence on manual labor and reduce labor costs. In addition, the automated operation of the assembly line can also reduce material waste, improve production efficiency, thus further reducing the unit cost of production.

3. Improve product quality: automated equipment can maintain a high degree of consistency in the production process, avoiding errors and instability that may occur in manual operation. Through precise control and monitoring systems, the assembly line can ensure that the quality of each product is up to standard.

4. Improve safety: In certain dangerous production environments, such as high temperature, chemical processing and other fields, the automated assembly line can replace manual operation, reduce the risk of workers working in harsh environments, and ensure the safety of production.

Fourth, the future development trend of automated assembly line manufacturers

With the continuous progress of science and technology, the application of automated assembly line will be further expanded, manufacturers are facing higher market demand. In the future, automated assembly line manufacturers will pay more attention to the application of intelligent technology, such as artificial intelligence, robotics, Internet of Things and big data analysis. These emerging technologies will make the automated assembly line more flexible and intelligent, realizing functions such as self-monitoring, fault prediction and autonomous adjustment.

In addition, the green concept will also become an important trend in the future design of automated assembly lines. Manufacturers will consider the efficient use of energy and recycling of waste in the design of production lines to meet the requirements of environmental protection.

Automated assembly line manufacturer is an important force to promote the process of modern industrial automation, through technological innovation, customized production and perfect after-sales service, to help enterprises achieve efficient and intelligent production mode. With the continuous development of intelligent technology in the future, the automated assembly line will further improve production efficiency, reduce costs, and bring more advanced production solutions for various industries.