Release Date:2024-08-15 11:55:36 Popularity:

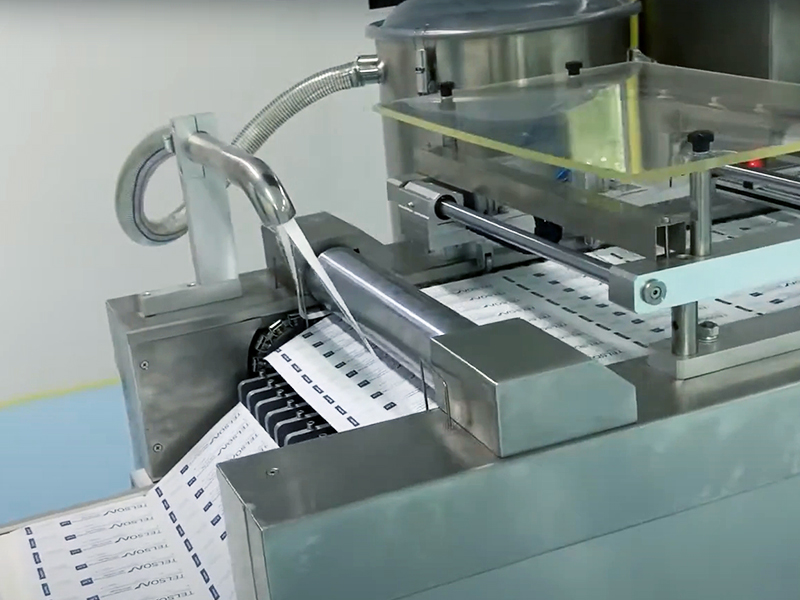

As an efficient packaging equipment, the automatic blister packaging machine occupies an important position in the field of modern industrial packaging. It softens the plastic film by heating it, and then forms it into packaging materials of various shapes by vacuum adsorption or pressure molding. It is widely used in food, electronic products, daily necessities, medicine and other industries. This article will explore the working principle, main components, application fields and advantages of the automatic blister packaging machine in modern industry.

1. Working principle of automatic blister packaging machine

The core working principle of the automatic blister packaging machine is to heat the plastic film to soften it and make it plastic, and then use vacuum adsorption or pressure to make the plastic film close to the mold surface to form the required packaging shape. Its working process generally includes the following steps:

1. Heating plastic film: First, the plastic film (usually PVC, PET, PS and other materials) is sent to the heating area, and the film is heated by the upper and lower heaters to reach the softening temperature and ready for molding.

2. Molding mold: The softened film is sent to the molding area, and the mold is made in advance according to the required packaging shape. The mold is usually made of metal and can be single-cavity or multi-cavity to meet the packaging needs of different products.

3. Vacuum forming or pressure forming: In the forming area, the film is pressed against the mold surface by vacuum forming or pressure forming to form the required packaging shape. Vacuum forming is to evacuate the air in the mold to make the film close to the mold; while pressure forming is to apply air pressure on the surface of the film to make it fit the mold.

4. Cooling and cutting: The formed film is quickly cooled by a cooling device to ensure its shape stability. The packaging material is then cut into independent packaging units and prepared for the next step of filling and sealing.

5. Automatic filling and sealing: In many automatic blister packaging machines, the steps of forming, filling, and sealing are carried out continuously. The product is automatically filled into the already formed blister packaging, and then sealed by heat sealing or other means to form the final packaging product.

2. Composition and structure of automatic blister packaging machine

The automatic blister packaging machine consists of several key components, each of which plays a vital role in the packaging process:

1. Heating system: The heating system is one of the core components of the blister packaging machine. The heater heats the plastic film to the appropriate temperature for molding. The temperature control accuracy of the heating system directly affects the molding effect.

2. Molding mold: The molding mold determines the shape and size of the final package. The design and manufacturing process of the mold directly affect the precision and quality of molding. The mold can be customized according to product requirements to adapt to products of different shapes and sizes.

3. Vacuum and pressure system: The vacuum and pressure system is responsible for keeping the softened film close to the mold surface to ensure the molding effect. The vacuum system evacuates the air in the mold to make the film close to the mold, while the pressure system applies air pressure on the surface of the film to make it fit the mold.

4. Cooling and cutting system: The cooling system is used to quickly cool the formed film to prevent it from deforming in subsequent operations. The cutting system is responsible for cutting the formed film into independent packaging units for subsequent operations.

5. Automatic control system: Modern automatic blister packaging machines are usually equipped with advanced automatic control systems, which can set and monitor various parameters in the packaging process, such as temperature, pressure, speed, etc., through programming to ensure the stability and consistency of the packaging process.

3. Application fields of automatic blister packaging machines

Automatic blister packaging machines are widely used in modern industry, and their main application fields include:

1. Food industry: In the food industry, automatic blister packaging machines are widely used to package various foods, such as fruits, vegetables, cooked food, snacks, etc. Blister packaging can not only extend the shelf life of food, but also improve the display effect of products and attract consumers' attention.

2. Electronic products: Automatic blister packaging machines are often used to package electronic products and accessories, such as mobile phone accessories, batteries, headphones, etc. Blister packaging can effectively protect products and prevent collisions and damage during transportation.

3. Daily necessities: Daily necessities such as cosmetics, cleaning products, toys, etc. are also often packaged in blister packaging. Blister packaging can not only improve the grade of products, but also increase the beauty of their shelf display.

4. Pharmaceutical industry: In the pharmaceutical industry, automatic blister packaging machines are used to package various medicines, medical devices, etc. Blister packaging can ensure the safety of medicines, prevent pollution and moisture intrusion, and facilitate storage and transportation.

4. Advantages of automatic blister packaging machines

The wide application of automatic blister packaging machines in the modern packaging industry stems from its significant advantages:

1. Efficient production: Automatic blister packaging machines can achieve continuous automated production, greatly improving production efficiency, and are particularly suitable for large-scale production needs.

2. Beautiful packaging: Blister packaging machines can produce packaging that conforms to the shape of the product, improve the beauty and grade of the product, and also increase the market competitiveness of the product.

3. Product protection: Blister packaging provides good sealing and protection, which can effectively protect the product and extend its shelf life and service life.

4. Save labor costs: The automatic blister packaging machine has a high degree of automation, which can reduce manual operations, improve consistency and quality in the production process, and reduce labor costs.

5. Versatility: The automatic blister packaging machine can adapt to the packaging needs of products of various materials and shapes, and has a wide range of applicability.

As an important equipment in modern packaging technology, the automatic blister packaging machine has become an important tool for various industries to improve production efficiency and product quality with its high efficiency, precision and wide applicability. With the development of industrial automation, the functions and performance of blister packaging machines will continue to improve, bringing greater economic benefits and market competitiveness to enterprises. In the future, the automatic blister packaging machine will continue to play an important role in all walks of life and promote the progress and innovation of packaging technology.